Vacuum Cleaning Tool, Especially Hand-Held Nozzle, for a Vacuum Cleaner

a vacuum cleaner and hand-held technology, applied in the field of vacuum cleaners, can solve the problems that the alignment error of the holder provided in the housing of the support shaft does not affect the support action of the turbine, and achieve the effect of minimal power loss and minimal fluctuation of the power of the turbin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

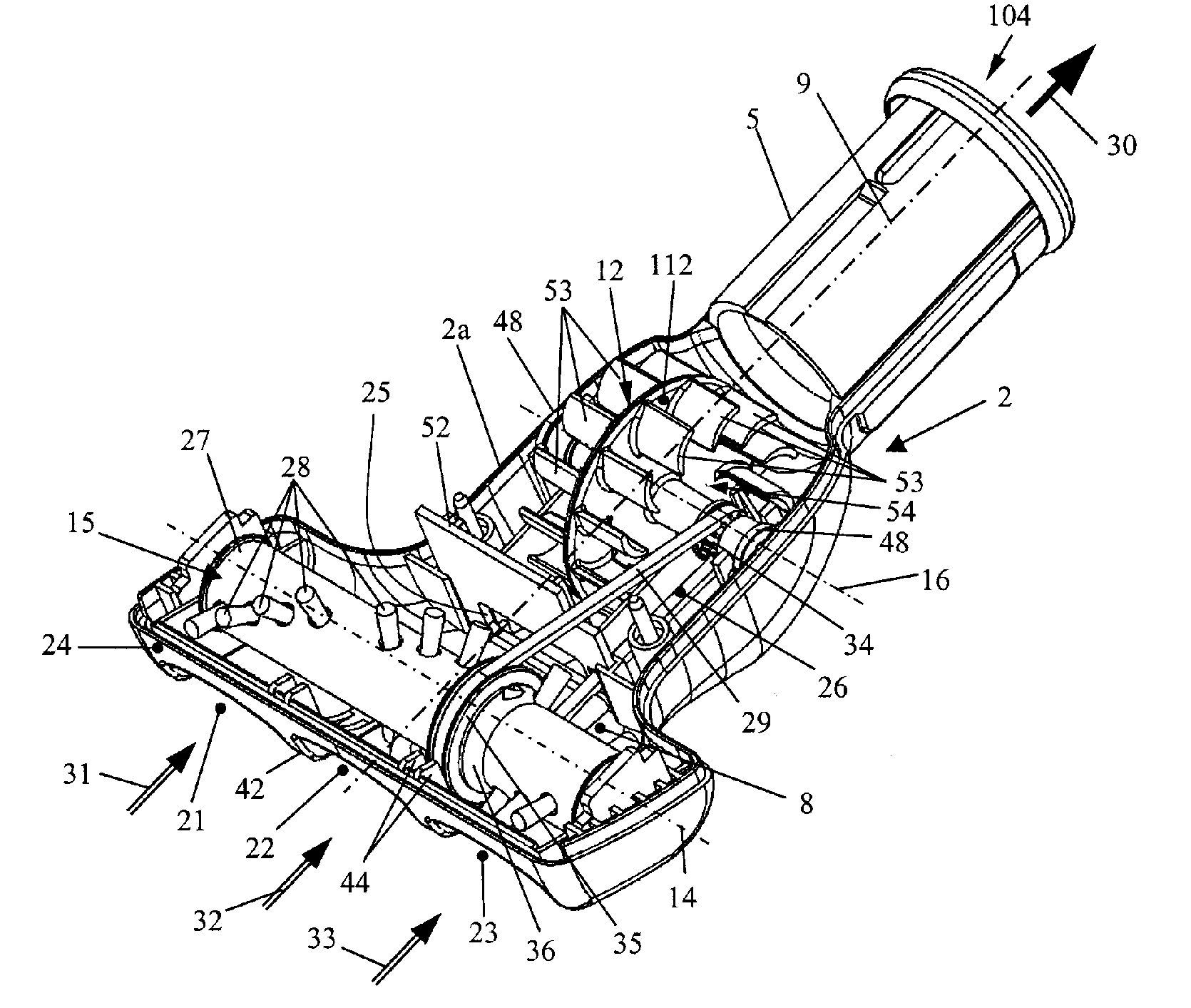

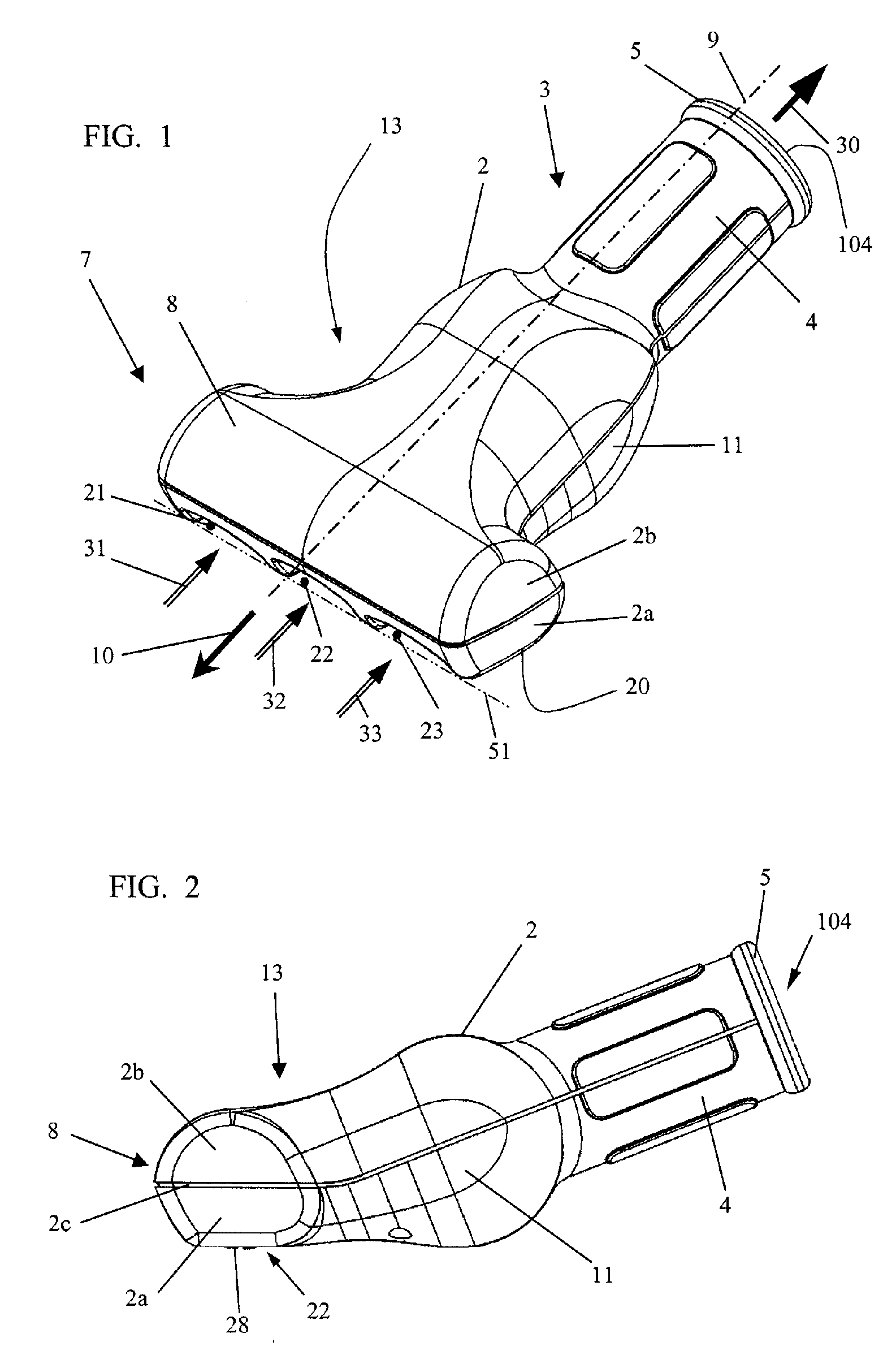

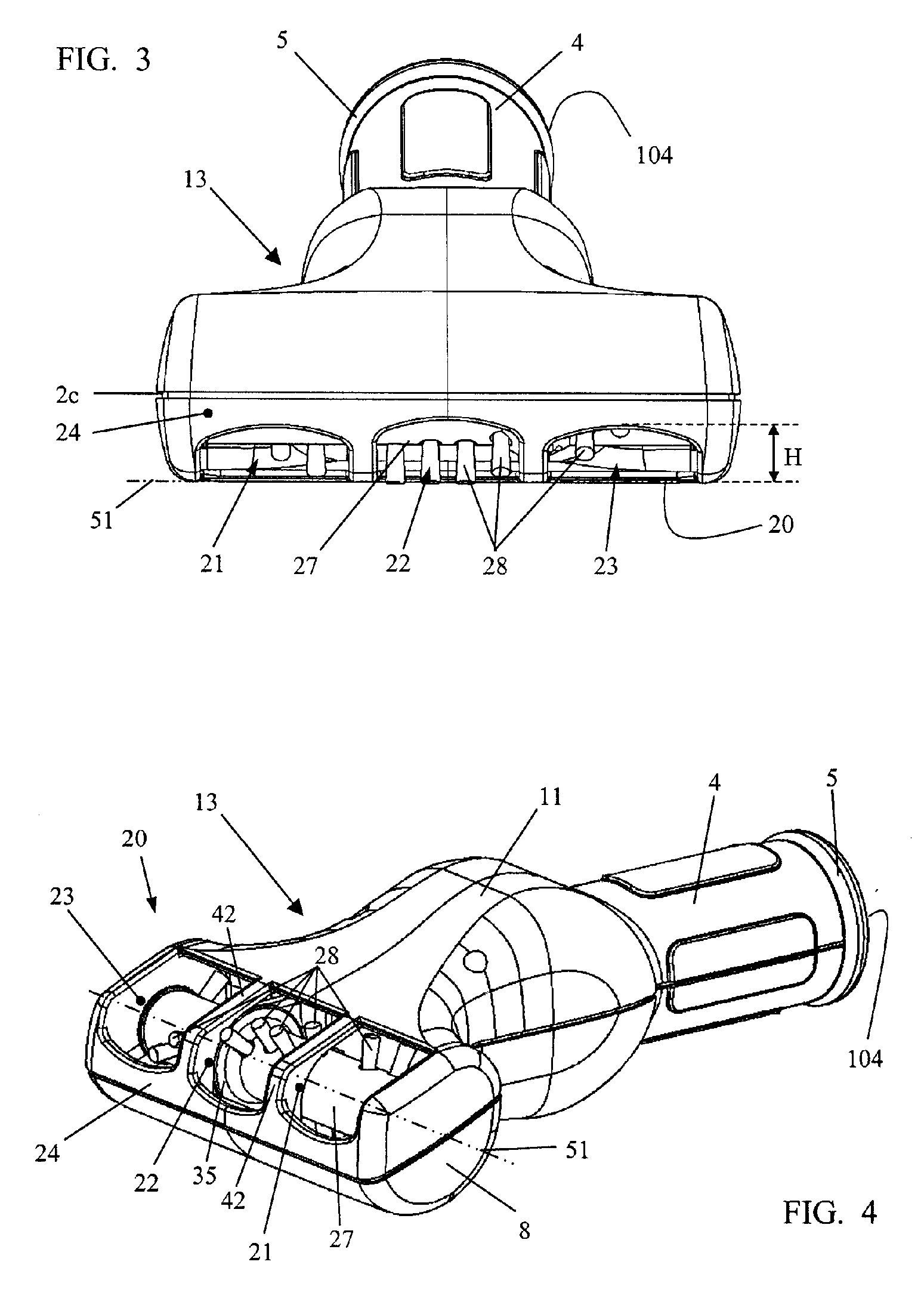

[0031] The vacuum cleaning tool 1 according to the invention illustrated in the Figures is provided to be connected to a vacuum hose of a vacuum cleaning device, not illustrated, particularly a vacuum cleaner. For this purpose, the housing 2 assembled from a housing top part 2b and a housing bottom part 2a is provided at its rearward end 3 with a connecting socket 4 that is formed as a unitary or monolithic part of the housing 2. As can be seen in particular in the section illustrations of FIG. 6 and FIG. 7, a socket insert 5 is inserted into the connecting socket 4 (see section illustration of FIG. 6); the socket insert 5 has a stepped inner diameter S1, S2 in order to receive in a vacuum-tight way connecting tubes of different diameters. For this purpose, the first section 71 formed at the open end 104 is provided with an inner diameter S1 that is greater than the inner diameter S2 of the inwardly positioned second section 72 that neighbors the turbine chamber 11. Preferably, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com