Ultra-pure hemodialysis concentrated solution manufacturing system and manufacturing technology

A technology of hemodialysis and manufacturing process, applied in dialysis systems, suction devices, etc., can solve problems such as contamination and non-ultra-pure raw and auxiliary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

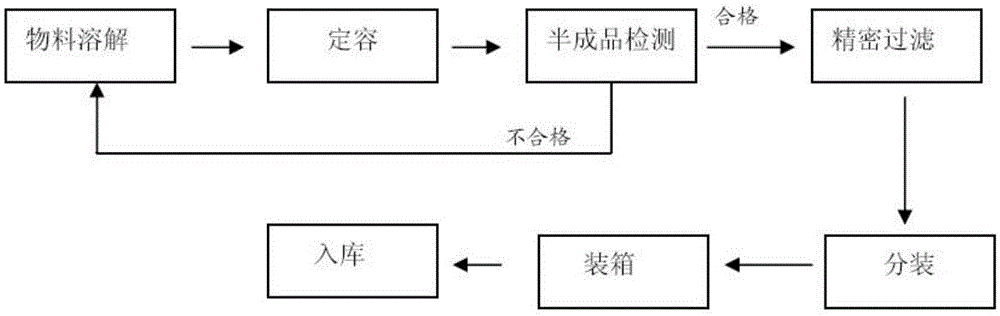

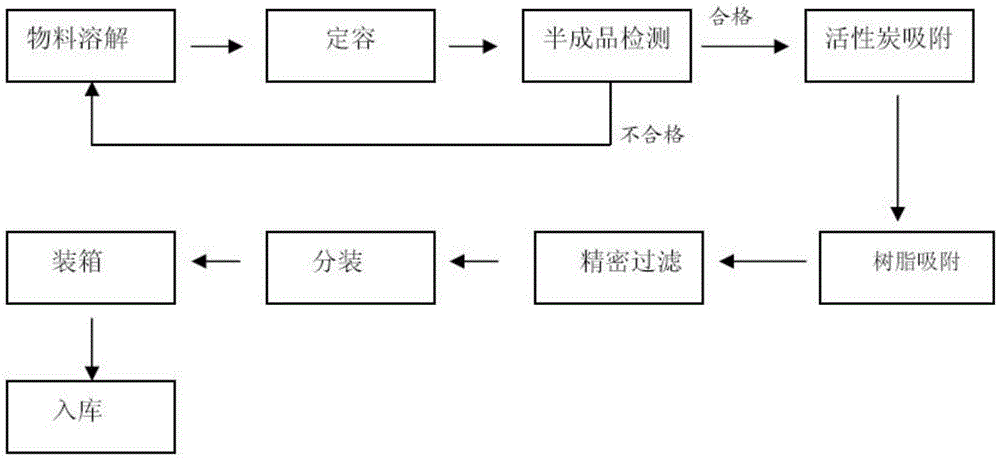

[0016] The following is attached with the manual figure 2 , 3 , the ultra-pure hemodialysis concentrate manufacturing system and process of the present invention are described in detail:

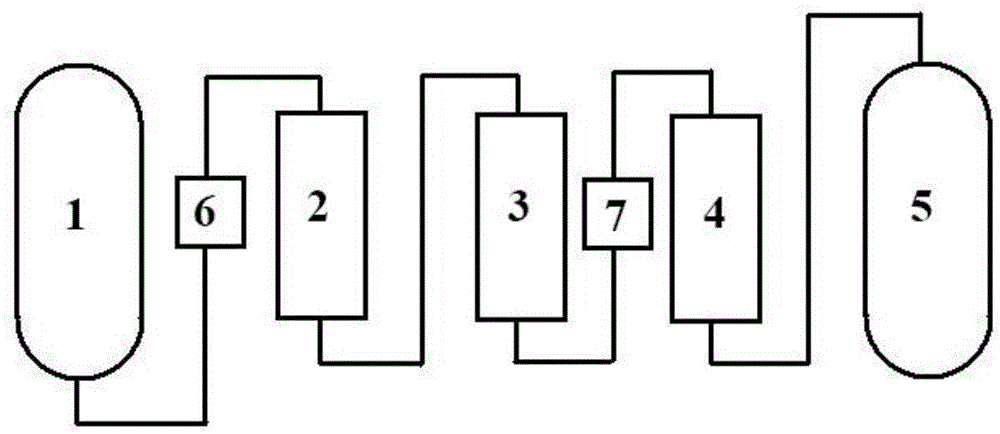

[0017] Such as image 3 As shown, the ultra-pure hemodialysis concentrate manufacturing system includes: a dynamic mixing and dissolving tank, an activated carbon adsorber, a modified resin adsorber, a precision filter, a liquid storage tank, and a set between the dynamic mixing and dissolving tank and the activated carbon adsorber The first pressure regulating pump, the second pressure regulating pump arranged between the modified resin adsorber and the precision filter; the dynamic mixing and dissolving tank has a heating function; the materials used are: sodium chloride, potassium chloride, chlorine Calcium chloride, magnesium chloride, glacial acetic acid, sodium bicarbonate; the manufacturing process includes: mixing and dissolving materials, constant volume, semi-finished product in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com