Method for recovering sulfuric acid from waste acid produced by anthraquinone production

A production process, anthraquinone waste acid technology, applied in the direction of sulfur trioxide/sulfuric acid, etc., can solve the problems of complex operation and low added value of products, and achieve the effects of simple operation, reduced consumption, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

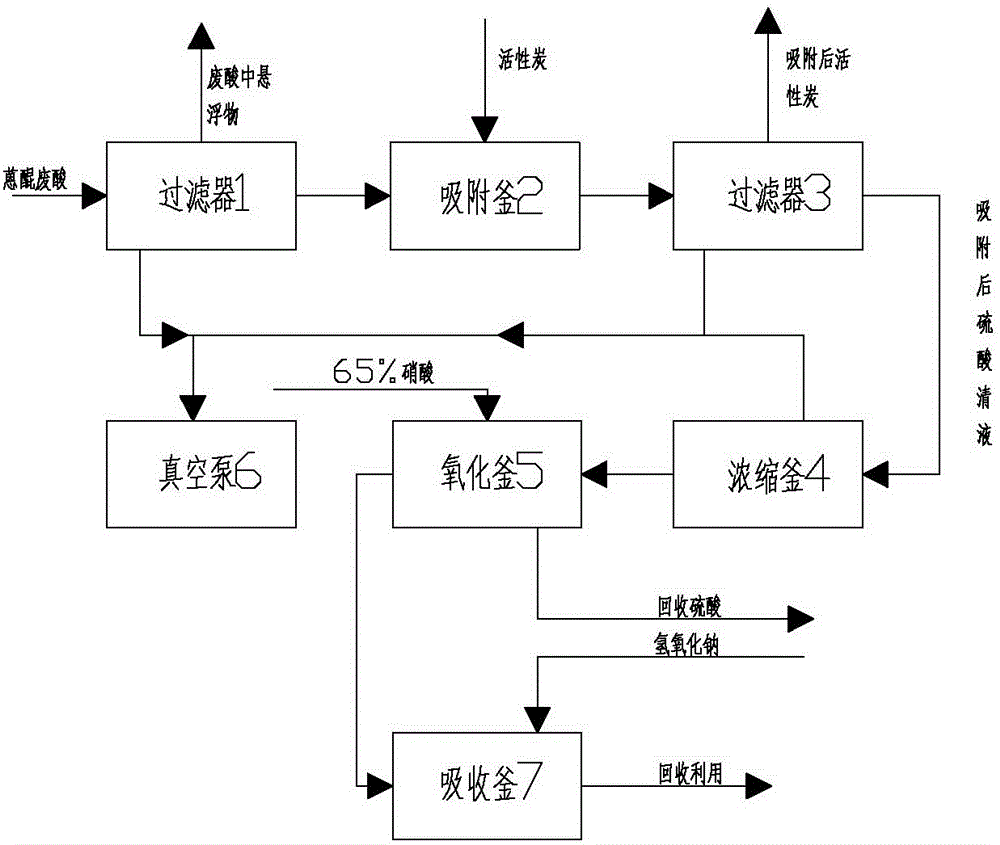

[0015] The present invention will be further described below in conjunction with specific embodiments and drawings:

[0016] Activated carbon adsorption and nitric acid oxidation are used to treat the anthraquinone waste acid under the following method conditions: the anthraquinone waste acid is subjected to solid-liquid separation in the filter 1, and the suspended matter in the waste acid is separated to obtain a relatively pure waste acid solution. After the spent acid solution reaches the adsorption tank 2, add 3% of its weight activated carbon to the spent acid solution, turn on stirring and heating, raise the temperature to 80°C to stop heating, and stir to maintain the tank temperature for 2 hours, then pass through the filter 3 for solid-liquid Separate. The temperature of activated carbon during adsorption is 50-90°C. The waste acid filtrate separated by the filter 3 is sent to the concentration tank 4, and the concentration tank is heated to 180-200°C under the vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com