Cooling liquid recovery system of vertical machining centre

A recovery system and coolant technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of no impurity reminder function, no separation of coolant and other impurities, etc., so as to facilitate chip removal and prevent blockage , the effect of timely reminder function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

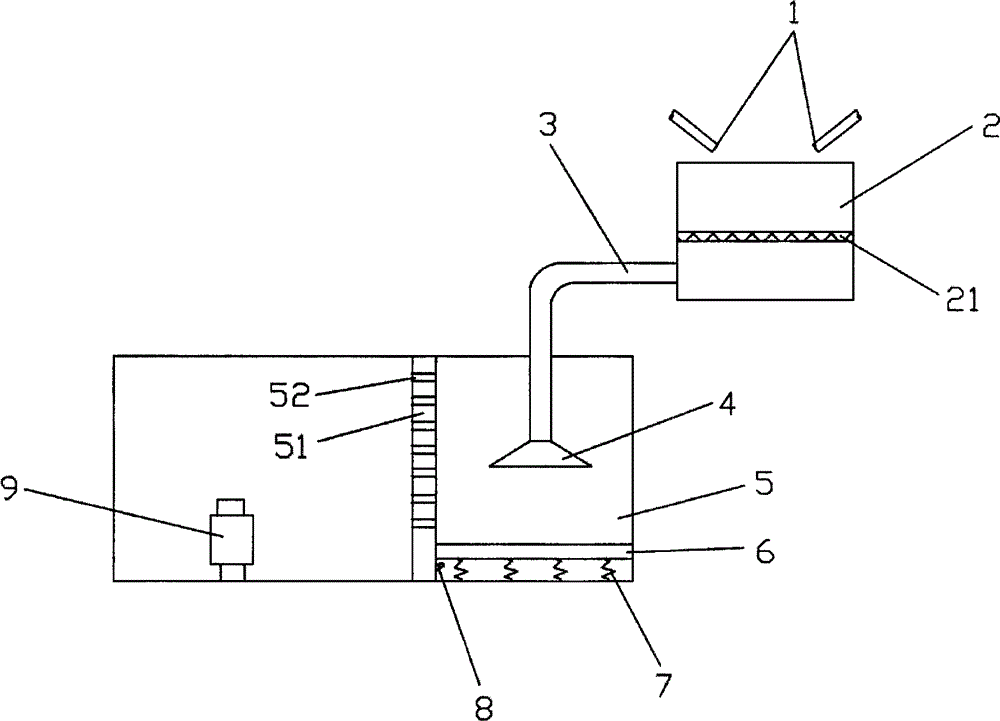

[0012] Such as figure 1 As shown, a coolant recovery system for a vertical machining center includes a coolant inlet 1 and a primary filter box 2 for collecting liquid flowing out of the coolant inlet 1, and a filter screen is arranged in the primary filter box 2 21. The primary filter box 2 is also connected with a liquid outlet pipe 3, and the liquid outlet pipe 3 is also connected with a water outlet nozzle 4, and the liquid flowing out from the water outlet nozzle 4 flows into the final filter box 5, and the water outlet nozzle 4 Extending into the final filter box 5, the final filter box 5 below the water outlet nozzle 4 is provided with a magnetic adsorption plate 6 for absorbing iron filings, the bottom of the magnetic adsorption plate 6 is connected with one end of a spring 7, and the spring The other end of 7 is installed on the bottom of the ultimate filter box 5, and a switch 8 for controlling the opening and closing of the warning light is also provided under the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com