Mold type installation device for material pulling and removing

A technology for installing devices and modes, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as slow operation of equipment, economic losses, casualties, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

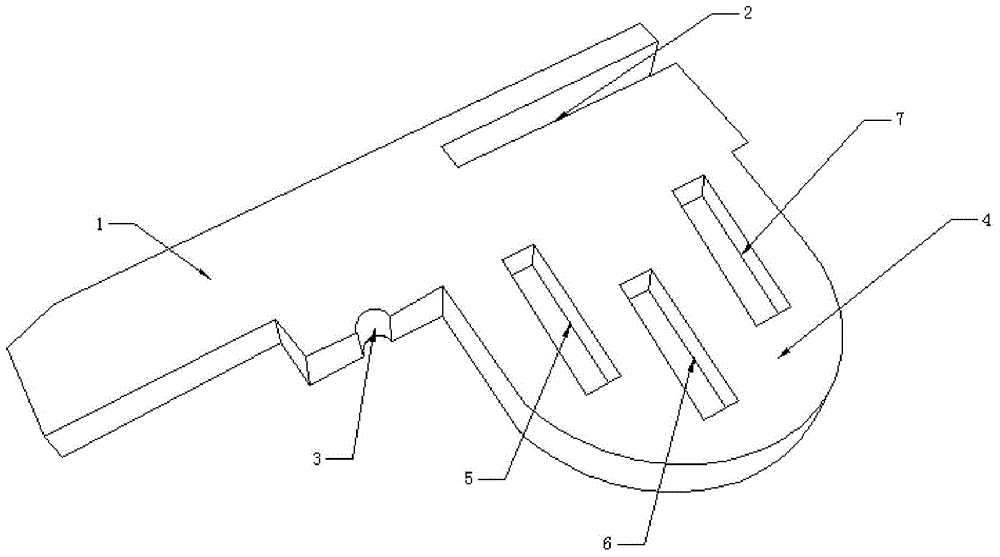

[0013] The pattern pulling material removal installation device includes the pattern lever 1, which is installed at the pulling place. The top of the front end of the pattern lever 1 is provided with a pull groove 2 for pulling the material, and the front side of the pattern lever 1 is provided with a groove for removing residual materials. The clearing installation plate 4, the side of the middle part of the mode lever 1 is provided with a fixing buckle 3 for fixing the device, and the middle part of the clearing installation plate 4 is provided with a first installation groove 5, a second installation groove 6, and a second installation groove for installing a cleaning device. Three mounting slots 7.

[0014] The first mounting groove 5, the second mounting groove 6, and the third mounting groove 7 are distributed in triangular positions.

[0015] Pulling chute 2 is provided with a material return trough inside.

[0016] The embodiments of the present invention have been de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com