Intelligent robotic arm

A technology of intelligent machinery and screw rods, which is applied in the field of mechanical arms, can solve the problems that the connecting rod mechanism is difficult to adapt and the mechanical arm is difficult to bend, and achieve the effects of compact structure, protection of screw rods, and large bending range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

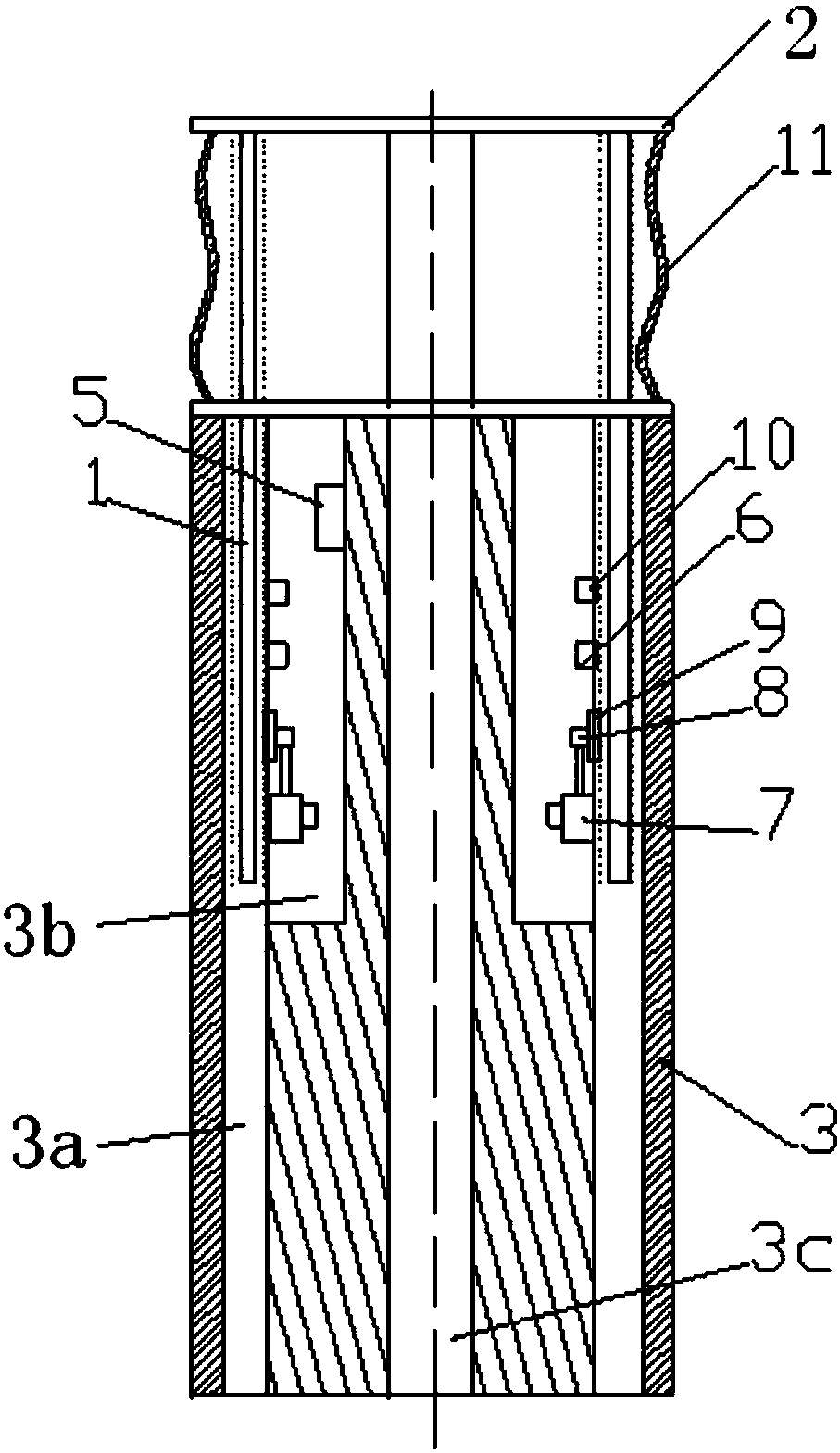

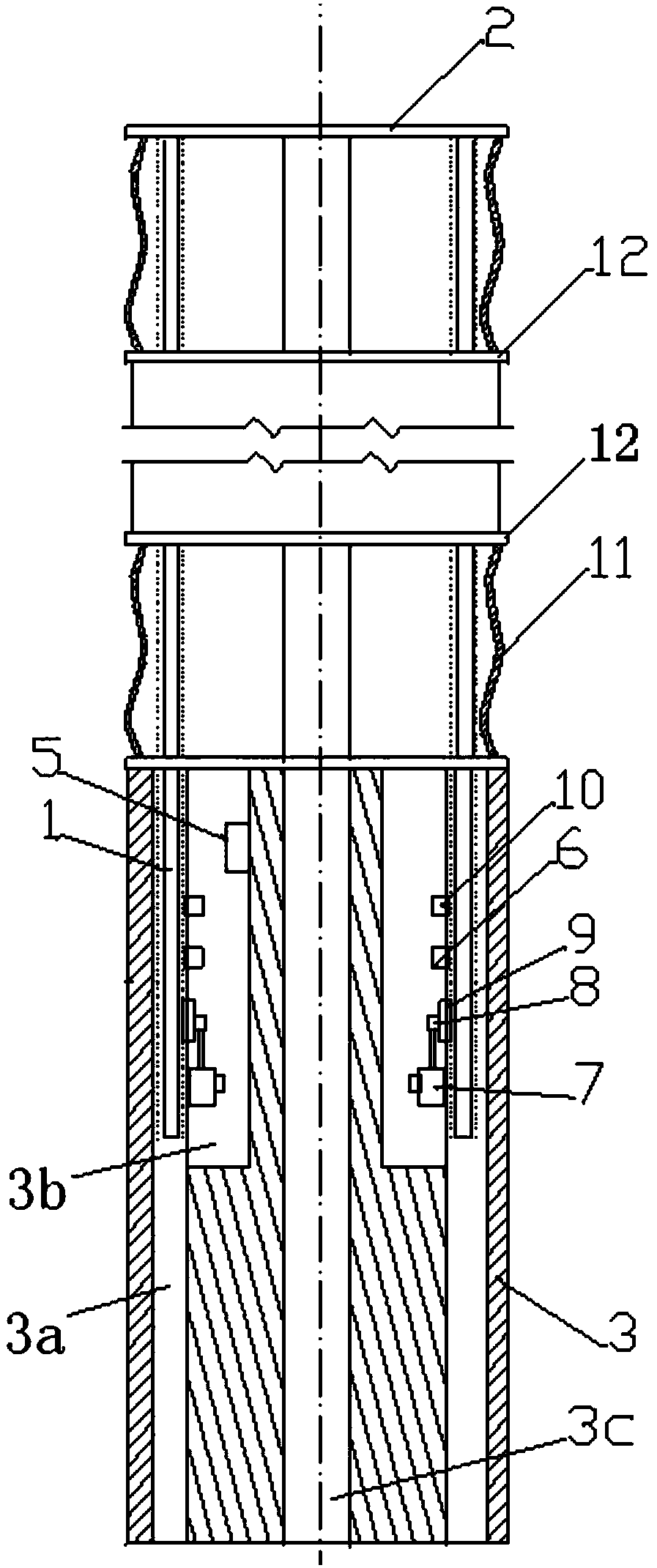

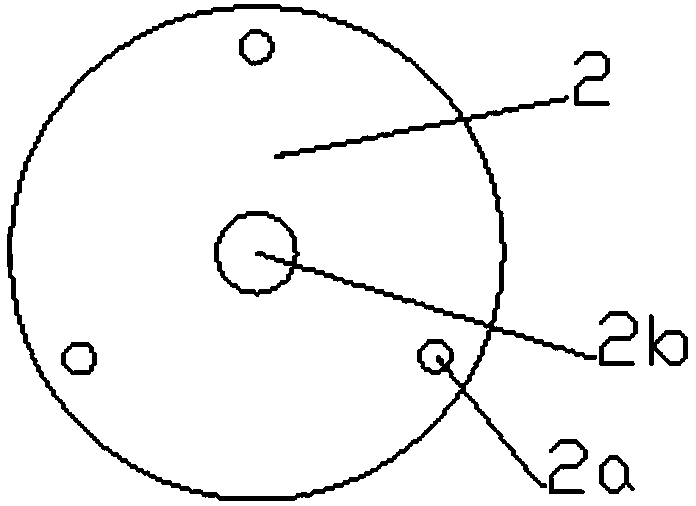

[0016] Embodiment: the present invention includes screw rods 1 and at least one joint. The screw rods 1 are at least three. The joints include a head module 2 and a base 3 provided with a guide hole 3a and an installation cavity 3b. The head module 2 is provided with at least three installation holes 2a, the number of the guide holes 3a is at least three, and one end of each screw rod 1 is connected with the universal ball head 4 arranged in the installation holes 2a, The other ends of the screw rods 1 are located in the guide holes 3a and are provided with a driving device for driving the screw rods 1, and the driving device is arranged in the installation cavity 3b. The present invention also includes a control mechanism, which includes a PLC controller 5 and a first position sensor 6 for collecting the displacement signal of the screw mandrel 1, which are all arranged in the installation cavity 3b, and the first position sensor 6 is at least Three and all are connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com