An injection-molded support bolt device and its construction method

An anchor rod and injection molding technology, which is applied in the direction of anchor rod installation, earthwork drilling, infrastructure engineering, etc., can solve the problems of restricting rapid support, low efficiency, and cumbersome anchor rod support technology, and achieves universality and practicability. , Improve the support effect and simplify the effect of the support process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

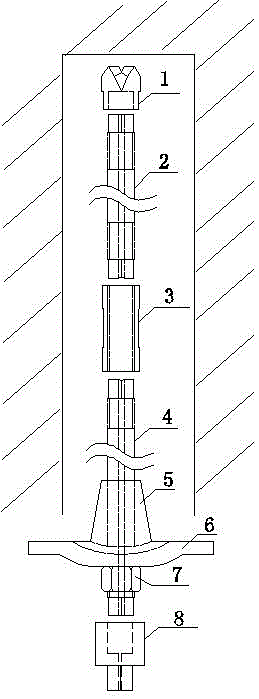

[0038] A kind of support bolt construction method, comprises the following steps:

[0039] a. Tightly connect the inner threaded end of the anchor drill bit with the outer threaded end of the front end anchor rod, the anode end of the front end anchor rod body is connected to the cathode end of the injection-molded hybrid connector, start the anchor drill rig to connect the anchor drill bit and the front end anchor The rod body is slowly pushed into the anchor end face, and at the same time, water is injected into the through hole of the anchor rod from the water supply pipeline, part of the water is injected into the drill hole through the through hole, and part of the water flows out through the injection molding mixing connector through the drainage pipeline;

[0040] b. Reserve the anode end of the front-end bolt body, remove the injection-molded hybrid connector and the bolt rig, and close the external water injection;

[0041] c. Tightly connect the other anode end of th...

Embodiment 2

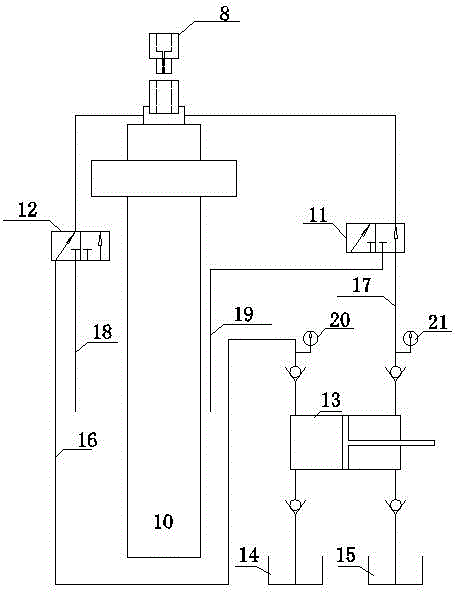

[0046] Such as Figure 5 Shown, another kind of support bolt construction method, comprises the following steps:

[0047] a. Tightly connect the inner threaded end of the anchor drill bit with the outer threaded end of the front end anchor rod, the anode end of the front end anchor rod body is connected to the cathode end of the injection-molded hybrid connector, start the anchor drill rig to connect the anchor drill bit and the front end anchor The rod body is slowly pushed into the anchor end face, and at the same time, water is injected into the through hole of the anchor rod from the water supply pipeline, part of the water is injected into the drill hole through the through hole, and part of the water flows out through the injection molding mixing connector through the drainage pipeline;

[0048] b. Reserve the anode end of the front-end bolt body, remove the injection-molded hybrid connector and the bolt rig, and close the external water injection;

[0049] c. Tightly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com