Bend output torque speed reducer

A technology of output torque and reducer, applied in the field of elbow output torque reducer, can solve the problems of inconvenient installation, small output torque, loose mounting bolts, etc., and achieve simplified bracket design, consistent rotation angle, output rotation big moment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

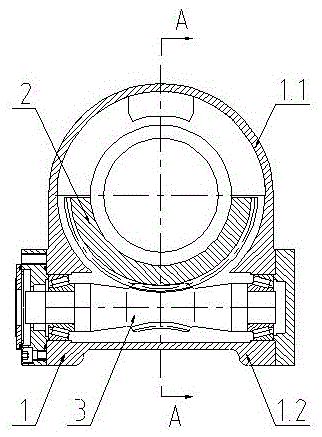

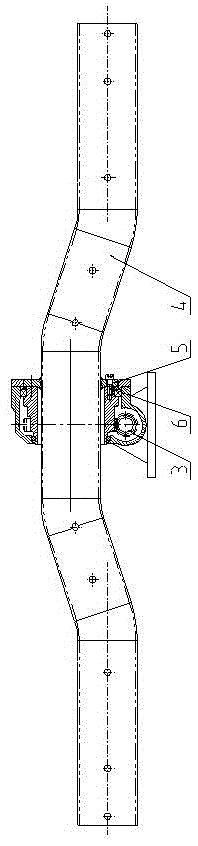

[0020] Such as figure 1 , figure 2 As shown, an elbow output torque reducer in this embodiment includes a base 1, the base 1 includes a seat ring 1.1 and a shaft housing 1.2, and a rotary gear 2 is arranged inside the seat ring 1.1, The shaft housing 1.2 is provided with a worm 3, the rotary gear 2 is meshed with the worm 3, the center of the rotary gear 2 is equipped with an output elbow 4, and the outer side of the output elbow 4 is fixedly provided with a flange 5, The flange 5 is fixedly connected with the rotary gear 2 through connecting bolts 6 .

[0021] In addition to the above-mentioned embodiments, the present invention also includes other implementations, and any technical solution formed by equivalent transformation or equivalent replacement shall fall within the protection scope of the claims of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com