Compression cable

A cable and core wire technology, applied in the field of cables, can solve problems such as cable core breaking, cable breaking, and cable rolling, achieving good compression resistance, reducing friction, and enhancing the ability to resist electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

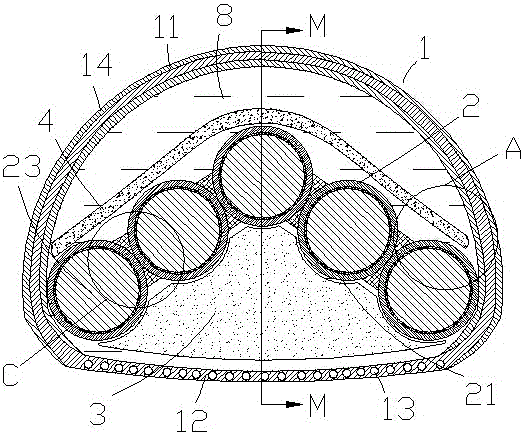

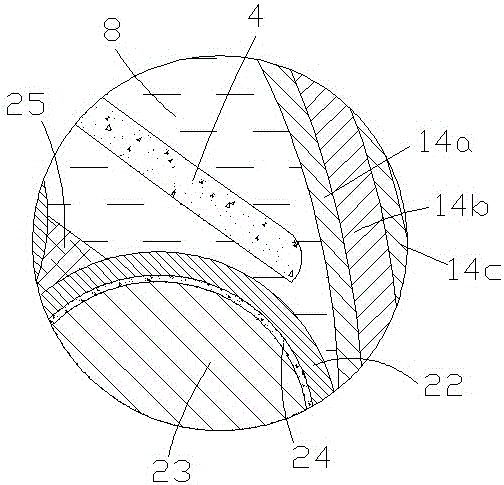

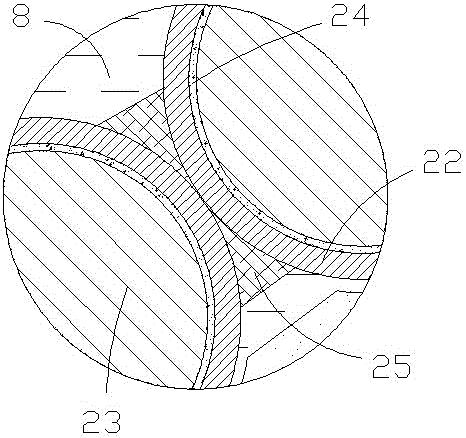

[0021] The compression-resistant cable of the present invention includes a cable body 1. The cable body 1 includes an armor layer 11 and several core wires 2 placed in the armor layer 11. It is characterized in that: the bottom of the armor layer 11 is flat, and the armor layer The bottom of the inner cavity of the loading layer 11 is provided with a flexible base 3, and the flexible base 3 is provided with seat grooves 21 having the same number as the core wires 2. The core wires 2 are fixed in the seat grooves 21, and the core wires 2 include metal cable cores 23. And the sheath 22 wrapped outside the metal cable core 23, the liquid lubricant layer 24 is filled between the sheath 22 and the metal cable core 23, the liquid lubricant layer 24 makes the sheath 22 and the metal cable core 23 not contact, relatively A connecting colloid 25 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com