horizontal reactor

A technology for horizontal reactors and reaction chambers, applied in chemical/physical/physical-chemical stationary reactors, detailed information, chemical instruments and methods of chemical/physical/physical-chemical reactors, etc. It can be fully utilized, affect the concentration distribution and temperature distribution, and affect the production capacity of the reactor, so as to shorten the production time, increase the reaction space, and prevent back-mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

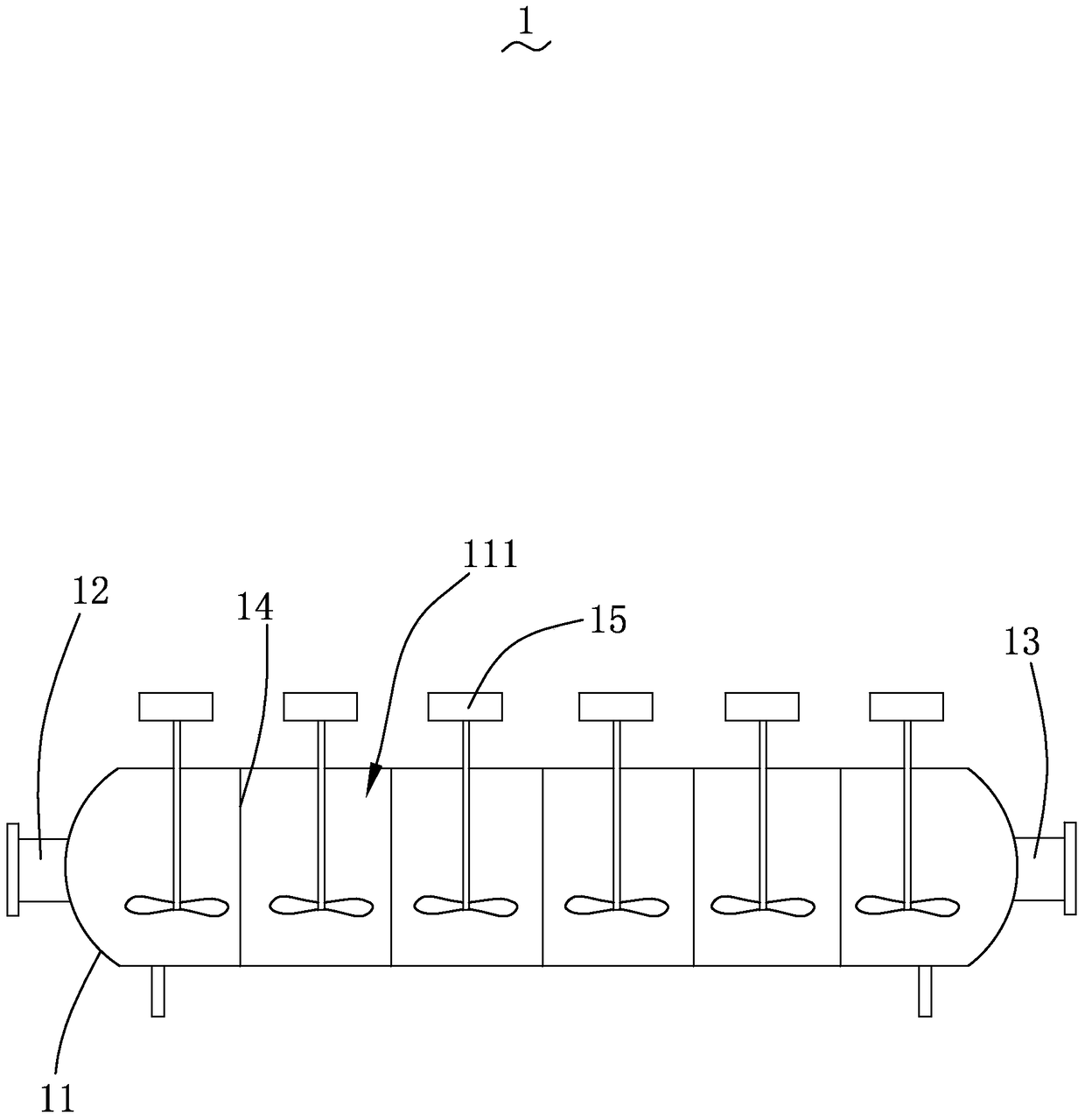

[0023] see figure 1 , is a schematic structural view of the horizontal reactor of the present invention. The horizontal reactor 1 includes a housing 11 with a receiving space (not labeled), a feed inlet 12 , a feed outlet 13 , a plurality of partitions 14 and a stirring device 15 . The feed port 12 and the discharge port 13 are located at both ends of the housing 11, the feed port 11 is used to transport the reaction material into the housing 11, and the discharge port 13 Used to output the reacted product. A plurality of partitions 14 are arranged at intervals in the housing space of the housing 11 perpendicular to the flow direction of the material along the material inlet 12 to the outlet 13 . The stirring device 15 is used to stir the materials so that the reactants can be mixed evenly and the reaction efficiency can be improved.

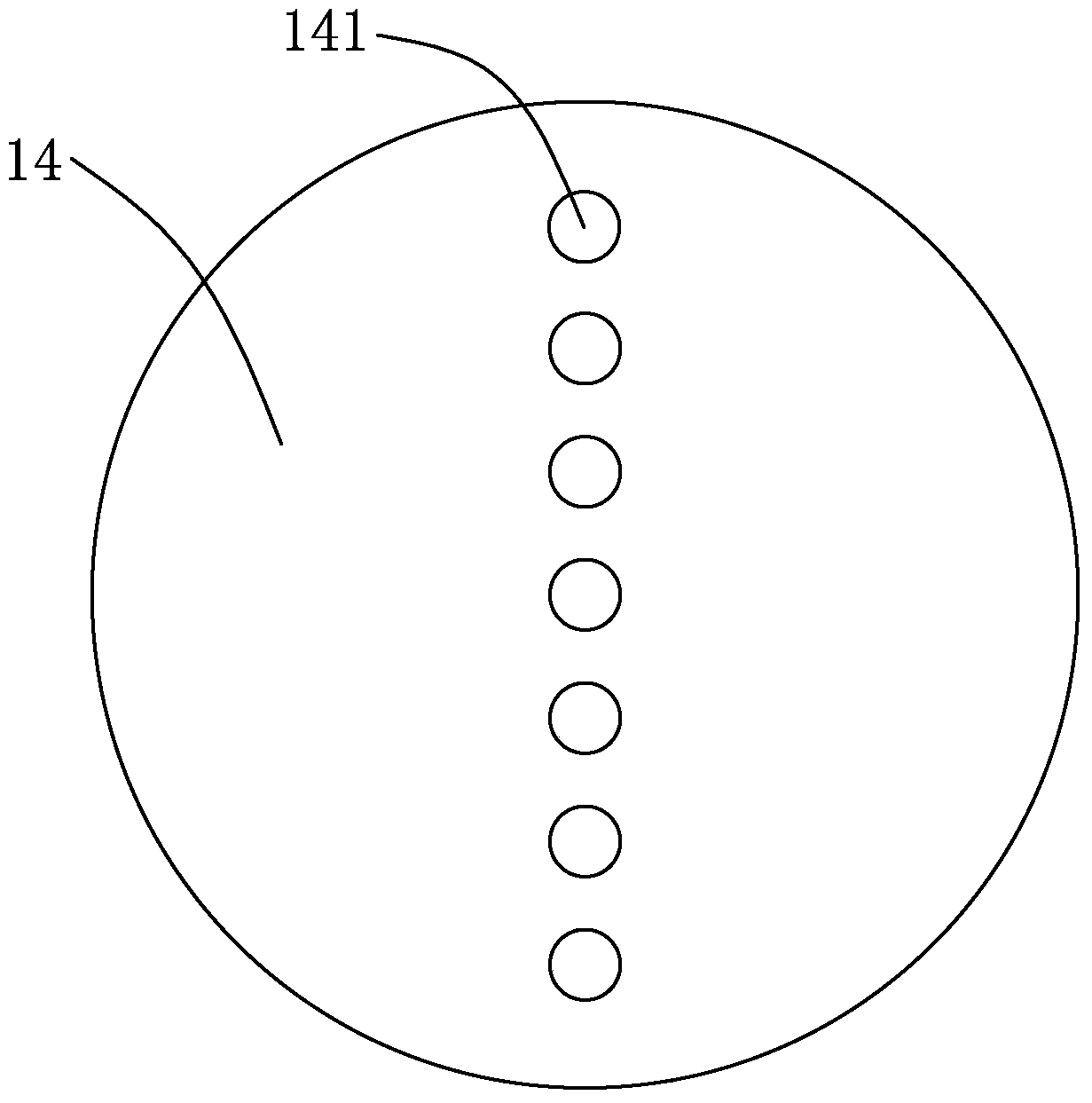

[0024] The number of the partitions 14 is 1-7. Correspondingly, the accommodation space of the housing 11 is divided to form 2-8 reaction ch...

Embodiment 2

[0034] The structure of the horizontal reactor in this embodiment is basically the same as that in Example 1, the difference lies in the distribution of the guide flow holes in the separator. The partition structure of this embodiment will be described in detail below.

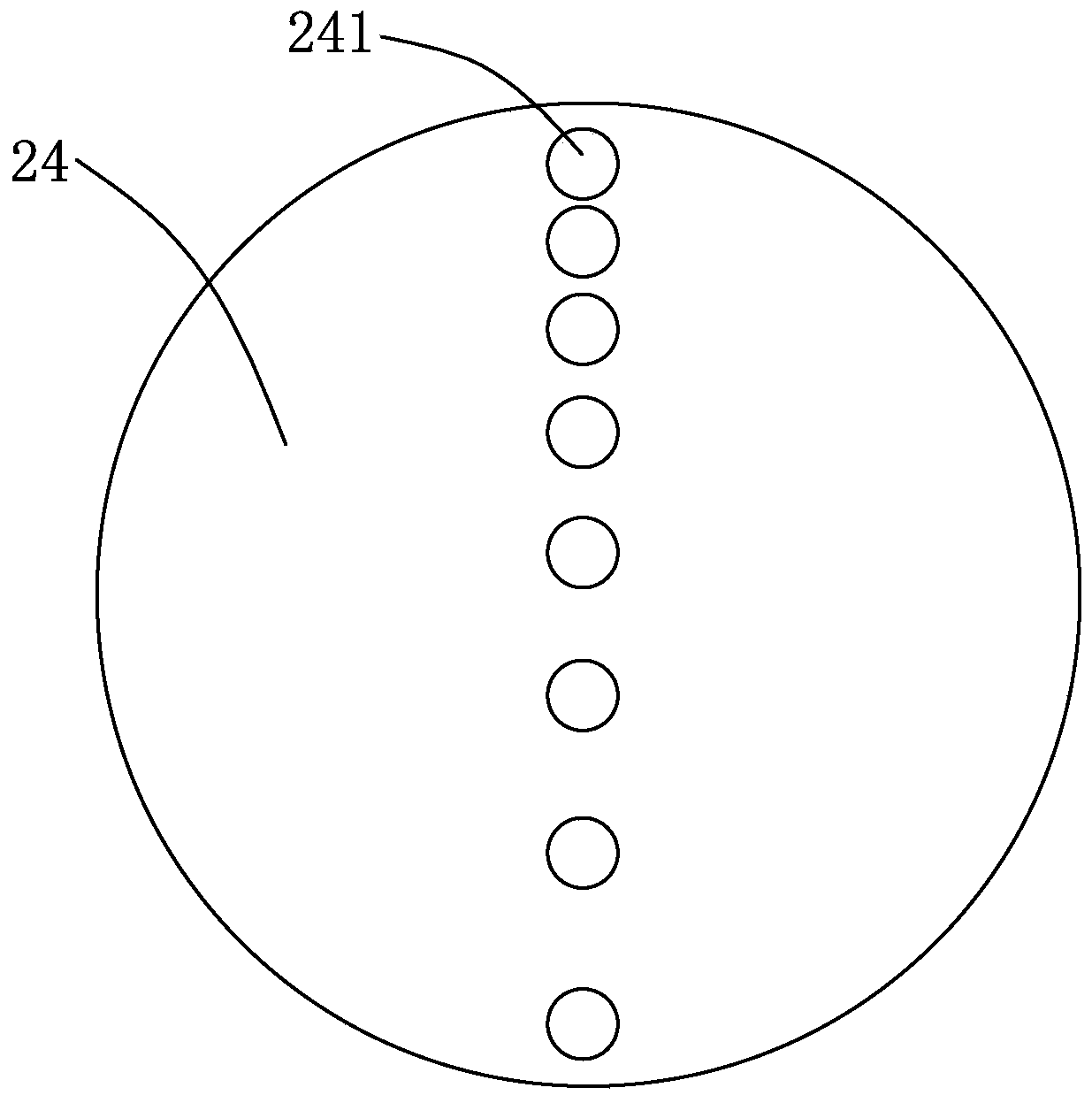

[0035] see again image 3 ,for figure 1 Schematic diagram of the second embodiment of the separator in the horizontal reactor shown. Each of the partitions 24 is provided with a plurality of diversion holes 241, and the diversion holes 241 are distributed along the depth direction of the material in the reaction chamber 111, that is, the diversion holes 241 correspond to different liquid levels. . The opening ratio of the guide flow holes 241 on each of the separators 24 is 0.02%-10%.

[0036] Along the direction from the bottom to the top of the reaction chamber 111 , the distance between two adjacent guide flow holes 241 gradually decreases, that is, the number of openings of the guide flow holes 241 at ...

Embodiment 3

[0040] The structure of the horizontal reactor in this embodiment is basically the same as that in Example 1, the difference lies in the distribution of the guide flow holes in the separator. The partition structure of this embodiment will be described in detail below.

[0041] see again Figure 4 ,for figure 1 The structural schematic diagram of Embodiment 3 of the separator in the horizontal reactor shown. Taking three consecutive partitions as an example, along the flow direction of the material, the three partitions are successively represented as 34a, 34b, 34c, and each of the partitions 34a, 34b, 34c is respectively provided with several guides. The flow holes are indicated as 341a, 341b, 341c, respectively.

[0042] The guide flow holes 341a, 341b, 341c are respectively distributed along the depth direction of the materials in the reaction chamber 111 . The opening ratio of the corresponding guide holes 341a, 341b and 341c on each of the separators 34a, 34b and 34c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com