Ultra-precise low-speed ball screw linear feeding device

A technology of ball screw and linear feed, which is applied in feeding devices, large fixed members, metal processing machinery parts, etc., can solve the problems of strong magnetic field, poor stability and dynamic performance of the device, inconvenient assembly and disassembly, etc. Achieve the effect of ultra-low speed smooth linear motion, reduce friction and fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

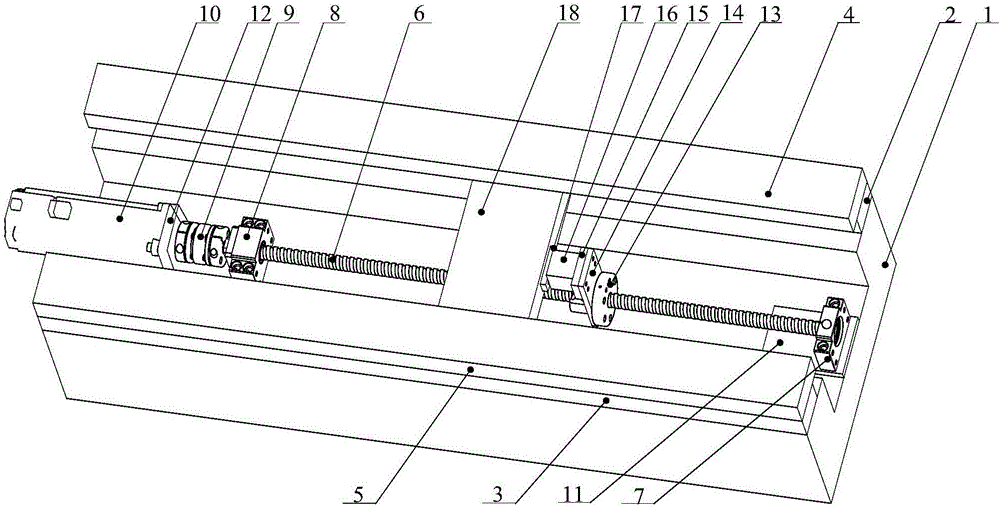

[0030] Such as figure 1As shown, the structure of the ultra-precision low-speed ball screw linear feed device is: the guide rail base 1 is U-shaped, and the upper part of one side is provided with the first side guide rail 2 and the first upper side guide rail 4 sequentially from bottom to top, and the other The upper part of one side is provided with the second side guide rail 3 and the second upper side guide rail 5 successively from bottom to top, and the left and right sides of the guide rail base 1 are parallel to each other and equal in height, and the first side guide rail 2 and the second side guide rail 3 are connected to each other. Parallel and equal height, the first upper side guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com