Air column mat convenient to inflate and manufacturing process thereof

A preparation process and air column technology, which is applied in the field of air column cushions that are easy to inflate and its preparation process, can solve the problems of low inflation efficiency and affecting packaging efficiency, and achieve the effect of high inflation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0031] preferred embodiment

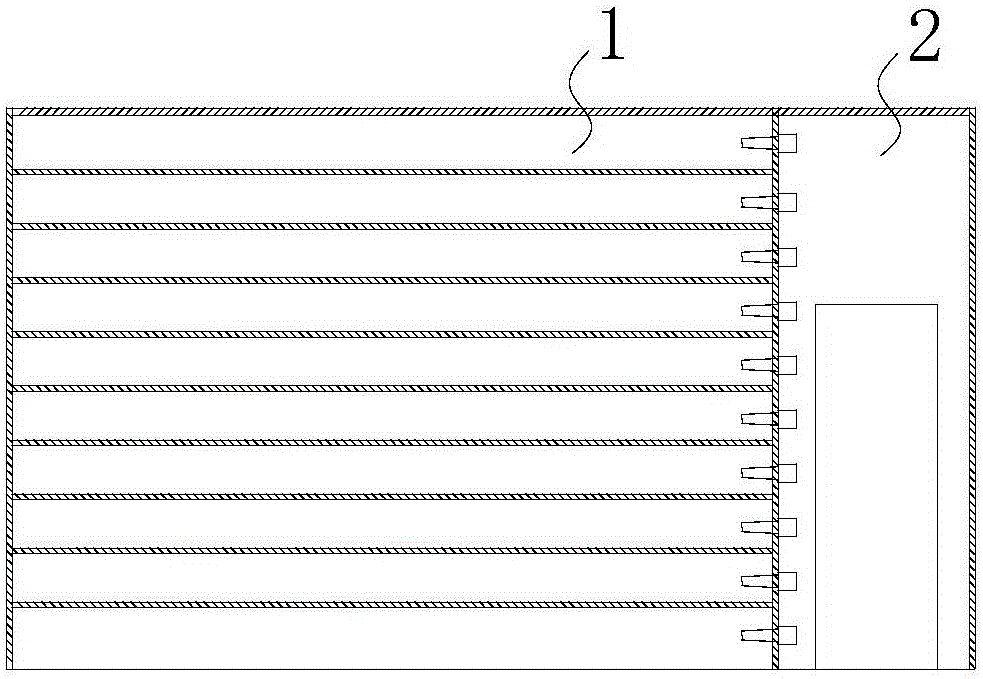

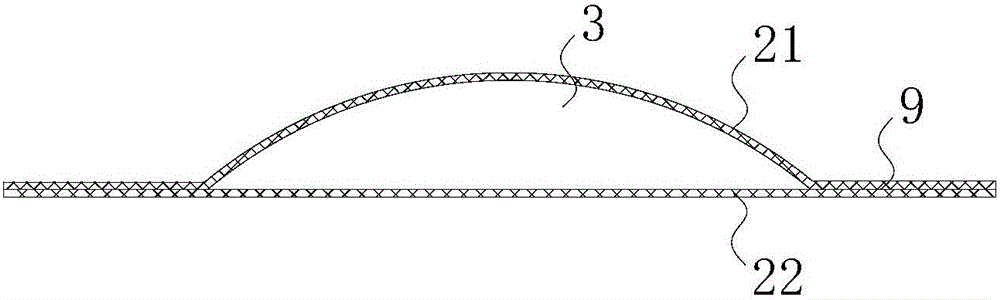

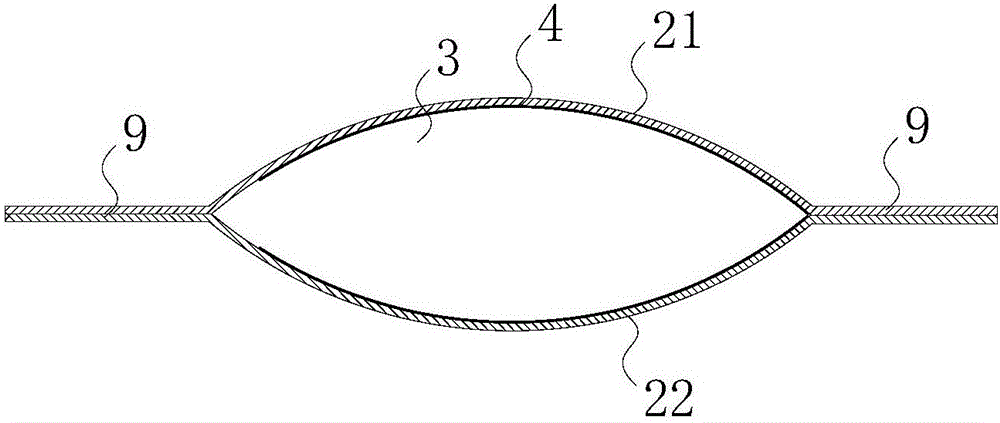

[0032] The preferred embodiment discloses an air column cushion which is easy to inflate. Such as Figure 1-Figure 6 As shown, the air column cushion described in this embodiment includes at least one set of air column groups, and each group of air column groups includes several air columns 1 separated by air column heat sealing lines, and one end of each group of air column groups or the corresponding An air intake channel 2 is arranged between the adjacent air column groups, and an inflatable port 3 is left between the first sealing film 21 and the second sealing film 22 constituting the air intake channel 2. Channel 2 to inflate the corresponding air column group.

[0033] The present embodiment is convenient to inflate the air column cushion air inlet channel 2 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com