Automobile engine air distribution cam suitable for variable two-stage air valve lift

A technology of automobile engine and valve lift, applied in the direction of valve driving device, valve details, etc., can solve the problems of not being able to adapt to different requirements of valve lift, and achieve the effects of improving inflation efficiency, avoiding resonance, and improving power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

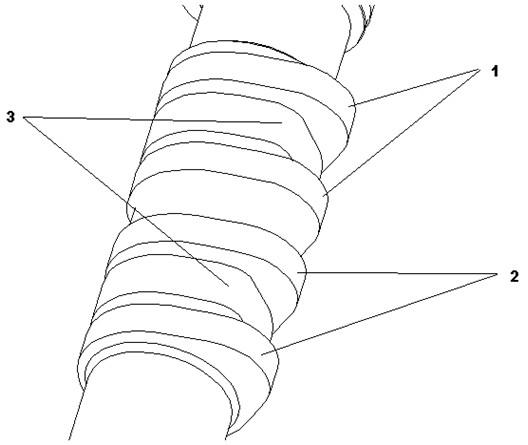

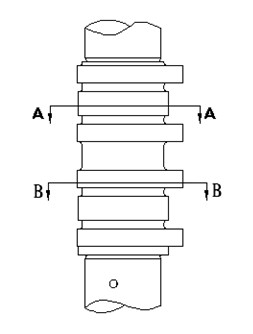

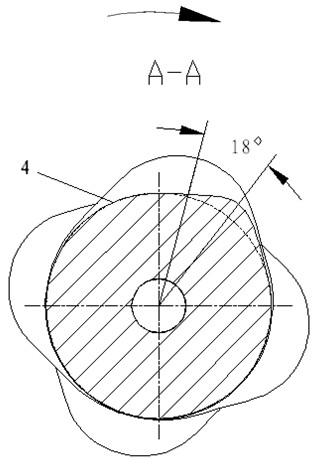

[0019] see figure 1 , figure 2 , image 3 and Figure 4 , two high-lift cams 1, 2 and one low-lift cam 3 are designed for one valve, and the low-lift cam 3 is arranged between the two high-lift cams 1 and 2. The angle between high-lift cams 1 and 2 and low-lift cam 3 is 18°, the maximum deviation of valve lift is less than ±0.05mm, the width of high-lift cam is 7.1mm, and the width of low-lift cam is 9.2mm. The radius of the base circle 5 of the high-lift cam is different from the radius of the base circle 4 of the low-lift cam, the radius of the high-lift base circle is 17.745mm, and the radius of the low-lift base circle is 16.61mm.

[0020] see Figure 5 and Figure 6 , the two cam buffer sections are designed differently according to the structural needs, the height 6 of the buffer section of the high-lift opening section is 0.42mm, the opening speed is 0.01mm / deg, the height 7 of the buffer section of the closing section is 0.52mm, and the closing speed is 0.02mm / de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com