Fixed-frequency nonlinear rubber vibration isolator for floating slab track and design method

A rubber vibration isolator, nonlinear technology, applied in the design of fixed-frequency nonlinear rubber vibration isolators, in the field of fixed-frequency nonlinear rubber vibration isolators, can solve the problem that the vibration isolation performance of floating plates cannot be further improved, and the condition of heavy vehicles The vertical displacement of the track is large and the vibration isolation performance cannot be provided, so as to achieve the effect of easy maintenance, stable vibration isolation performance and vertical displacement suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

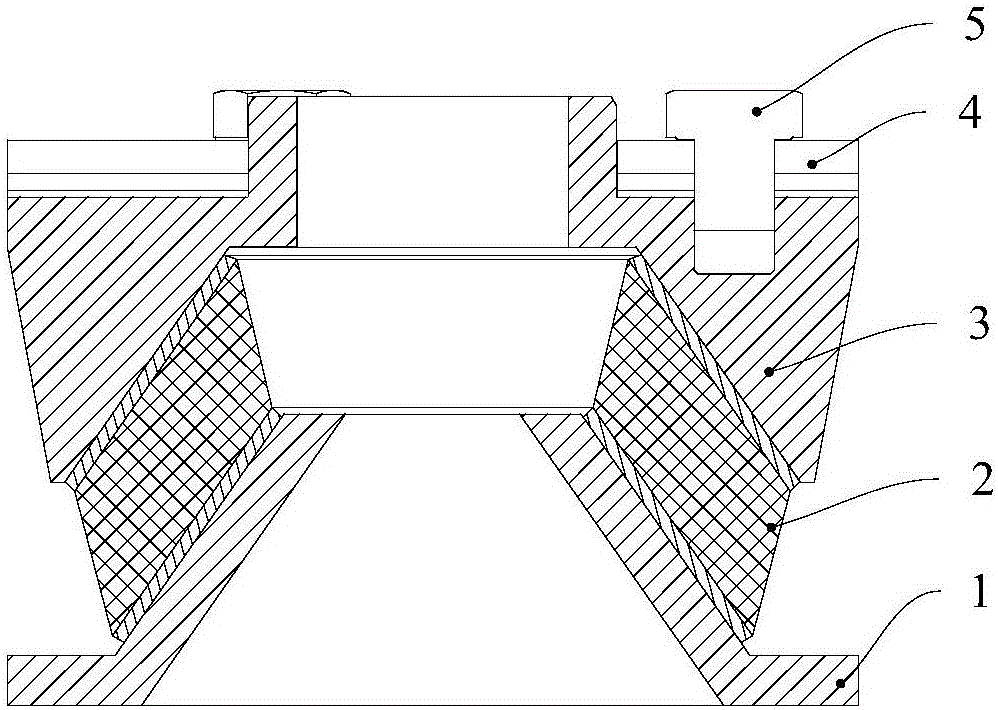

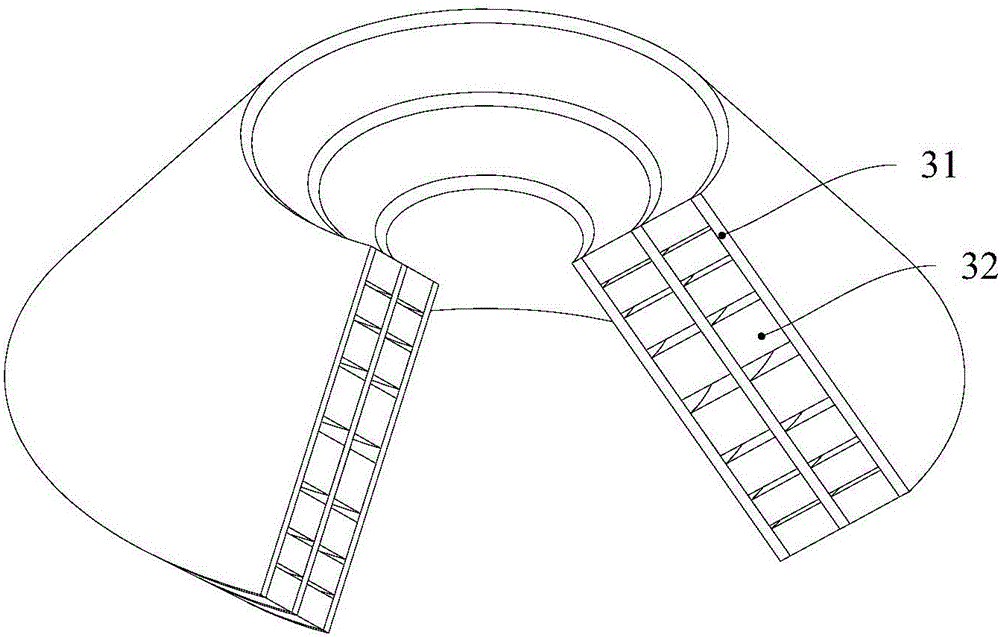

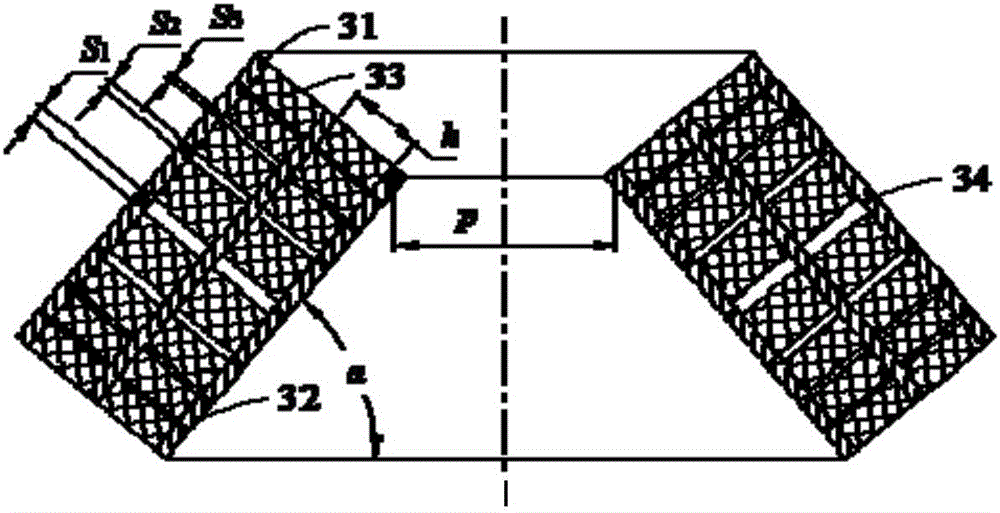

[0029] refer to figure 1 , figure 2 with image 3 , a fixed-frequency non-linear rubber vibration isolator for a floating slab track of the present invention, comprising a base 1, a conical rubber pile 2, an upper support seat 3, a height-adjusting backing plate 4 and a locking screw 5, the top surface of the base 1 It fits with the inner tapered surface of the conical rubber pile 2, and the bottom surface of the upper support seat 3 fits with the outer tapered surface of the tapered rubber pile 2. The conical rubber stack 2 includes a coaxial inner conical steel disc 31, an outer and inner conical steel disc 32, and an inner conical steel disc 31, an outer and inner conical steel disc 32 that is fixedly connected to it. At least one layer of tapered rubber body, the tapered rubber body is composed of tapered rubber ring units 34 spaced apa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com