Suspension type damper used for high speed rotating machine

A high-speed rotation and damper technology, applied in the field of mechanical parts, can solve the problems of low natural frequency oil film viscous damping performance, low first-order natural frequency of flywheel energy storage system, small radial stiffness of axial permanent magnet bearing, etc. Viscous damping, good processing performance and performance, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

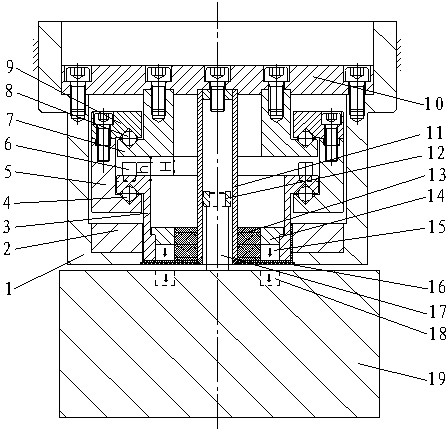

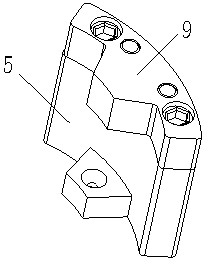

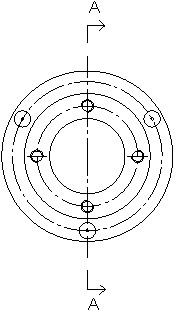

[0014] like Figure 1 to Figure 4 As shown, a suspension damper used in high-speed rotating machinery of the present invention includes an oil film ring fixing frame 1, an oil film ring 2, an oil film journal 3, a ball fixing frame 7, a damper fixing plate 10, a sealing limiter Position post 11, soft magnetic ring 14, stator 15 of permanent magnet bearing, oil sealing plate 16 and combination pendant. The oil film ring fixing frame 1 is an annular body. The oil film ring fixing frame 1 is fixed on the frame. The oil film ring 2, the oil film journal 3, the ball fixing frame 7, the damper fixing plate 10, the sealing limit post 11, the soft magnetic ring 14, the stator 15 of the permanent magnet bearing, the oil sealing plate 16 and the combination pendant are all fixed on the oil film ring. in rack 1. The upper part of the oil film ring fixing frame 1 is fixedly connected to the damper fixing plate 10 . A sealing limit post 11 is arranged in the cavity of the oil film ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com