Laying method for main cable of flat tension cable bridge and applied double-layer cable saddle

A flat-stayed cable bridge and cable saddle technology, applied in bridge construction, bridges, bridge parts, etc., can solve problems such as the limitation of the scope of application of the cable saddle, the large bending strength of the main cable wire, etc., and improve the stability and safety of the bridge. , Improve the scope of application, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

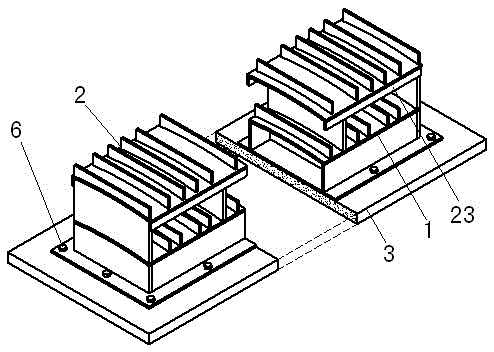

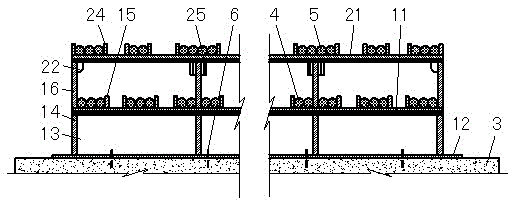

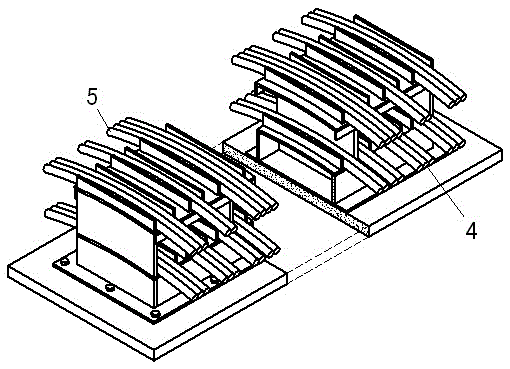

[0028] This example Figure 1-3 As shown, it consists of the lower cable saddle 1 and the upper layer cable saddle 2. The lower layer of cable saddle 1 is fixed on the foundation 3, while the upper layer of cable saddle 2 and the lower layer of cable saddle 1 are clamped. Both the lower cable saddle 1 and the upper layer cable saddle 2 are steel structures. like Figure 4-7 As shown, the lower cable saddle 1 includes a lower cable bearing plate 11 , a base plate 12 , a wing plate 13 , a lower partition 14 , a middle partition 15 and a supporting plate 16 . like Figure 8-11 As shown, the upper cable saddle 2 includes an upper cable board 21 , a horizontal clamping plate 22 , a vertical clamping plate 23 and an upper partition 24 . The lower cable bearing plate 11 and the upper cable bearing plate 21 are arc-shaped plates along the bridge direction, and are used to support the upper main cable 5 and the lower main cable 4 . An upper partition 24 is arranged above the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com