Railway vehicle axle box rubber anti-vibration pad with built-in dynamic vibration absorber

A technology for dynamic vibration absorbers and rail vehicles, which is applied in the installation of axle boxes, railway car body parts, bogies, etc., can solve the problem of high-frequency torsional vibration cracking of the frame, increased normal/abnormal load of the axle, and increased secondary suspension. Parts load and other issues, to achieve the effect of improving torsional fatigue reliability, improving lateral stability, and improving fatigue reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

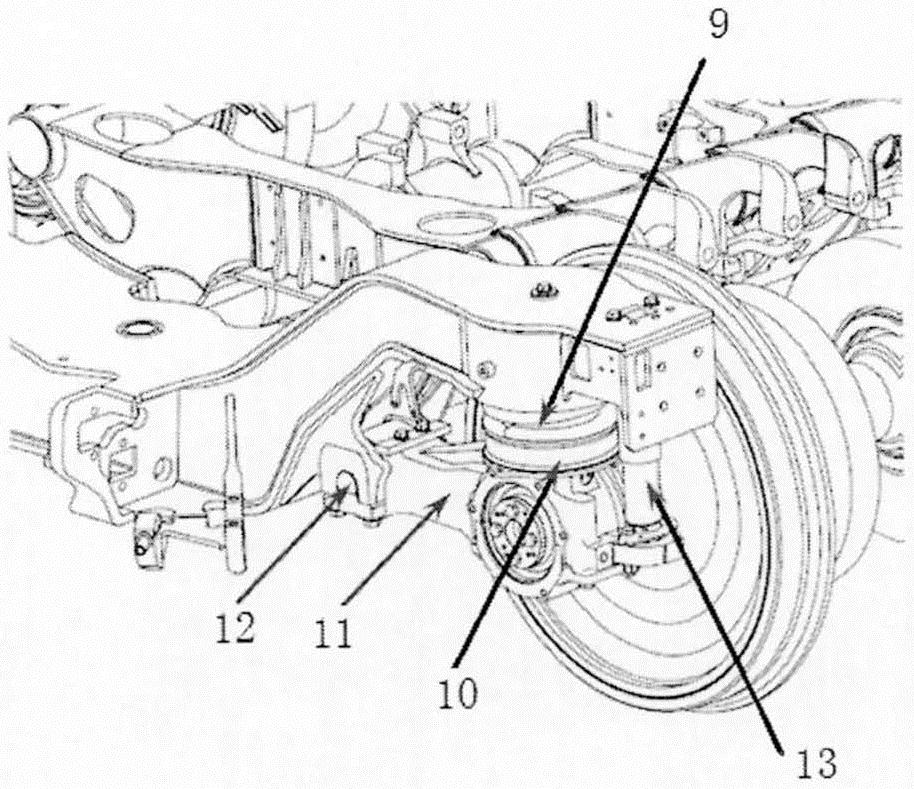

[0028] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

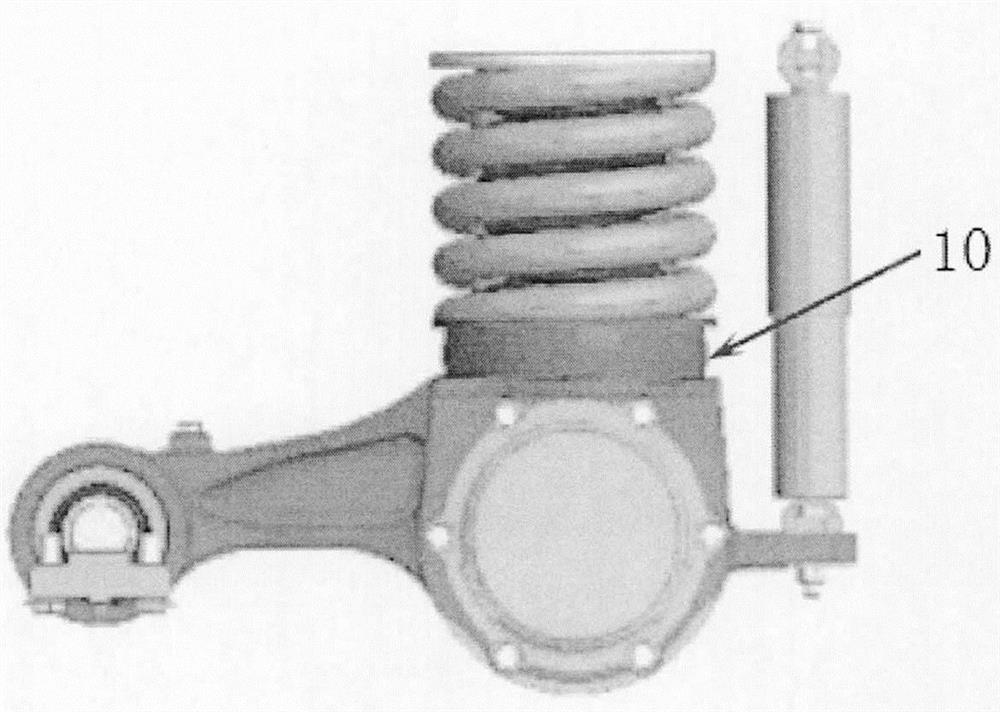

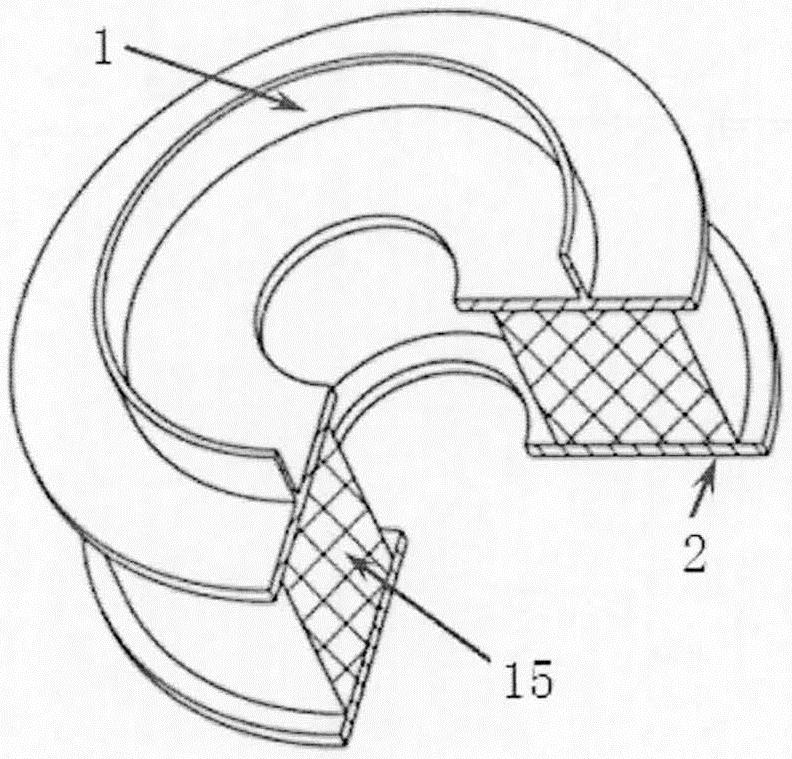

[0029] The upper and lower metal backing plates are circular flat metal sheet structures, and the lower backing plate is a metal ring thin plate structure, which is in contact with the top of the pivot arm axle box when installed; the upper backing plate is a metal ring thin plate plus an annular spring stop structure, During installation, the upper plane is in contact with the steel spring support ring used in combination with the inner and outer rings of the axle box, and the spring stopper is used to limit the spring position of the inner and outer rings to avoid bumping. The rubber body is vulcanized between the upper and lower backing plates, and the middle part of the whole / split rubber body is vulcanized and installed with a metal mass block as a dynamic vibration absorber. There is a certain space between the mass block and the upper and lower b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com