Drain flushing and cleaning system

A drainage pipe and sewage cleaning technology, which is applied in the direction of waterway system, sewer pipe cleaning, water supply equipment, etc., can solve the problems of low efficiency, large economic loss, poor drainage, etc., and achieve the effect of avoiding underground operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

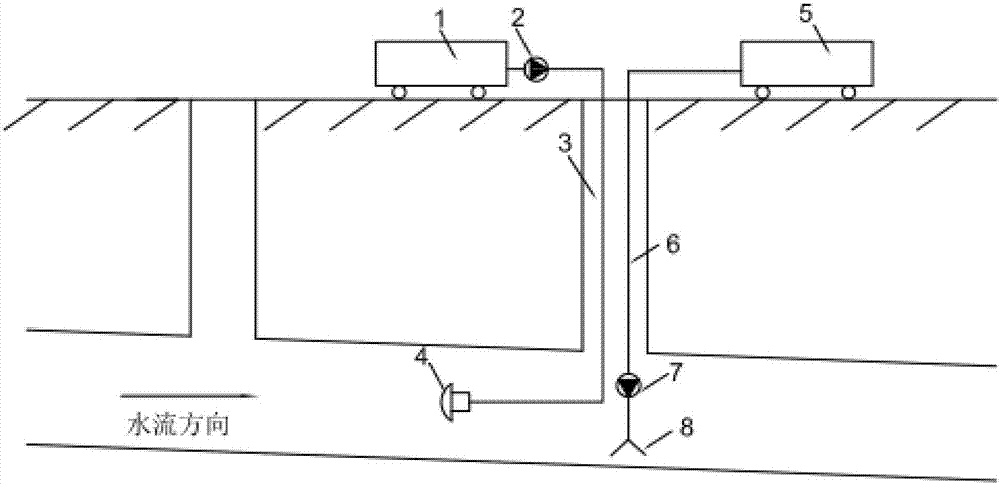

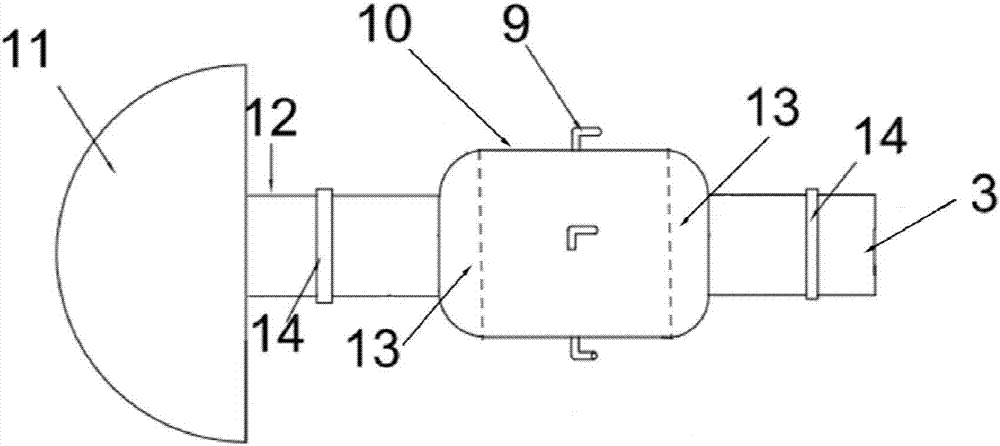

[0014] The flushing and cleaning system of the drainage pipeline, the flushing water tank 1, the high-pressure water pump 2 and the rotating multi-hole nozzle 4 are connected through a pressure-resistant hose 3 to form a set of flushing executive components. The water tank 1 is flushed, and the water flow is pumped into the cylindrical cavity 10 of the rotating multi-hole nozzle 4 through the high-pressure water pump 2, and is sprayed out from the water flow conduit 9. The conical mud suction port 8, the mud suction pipe 6, the sludge pump 7 and the ground sewage collecting vehicle 5 are connected as a set of cleaning executive components. Because the water flow conduit 9 has a jetting angle, the high-pressure water pump pumps the water in the water tank into the pressure-resistant hose 3 and shoots it out through the water flow conduit 9. When the water flow hits the wall,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com