Method for evaluating performance of multistage hydraulic jetting fracturing pipe column

A fracturing string and hydraulic jetting technology, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of no hydraulic jet fracturing string performance evaluation method, large cost loss, waste of resources, etc. , to achieve the effect of significant application effect and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In order to solve the problem of safety evaluation of multi-stage hydraulic jet fracturing strings and tools in horizontal wells, the present invention provides a performance evaluation method for multi-stage hydraulic jet fracturing strings, which is mainly applicable to multi-stage hydraulic jet fracturing in vertical wells and horizontal wells The safety analysis of pipe string performance can reduce costs and save resources, and has greater economic benefits and strong practicability.

[0036] A method for evaluating the performance of a multi-stage hydraulic jet fracturing string, the evaluation method comprising the following steps:

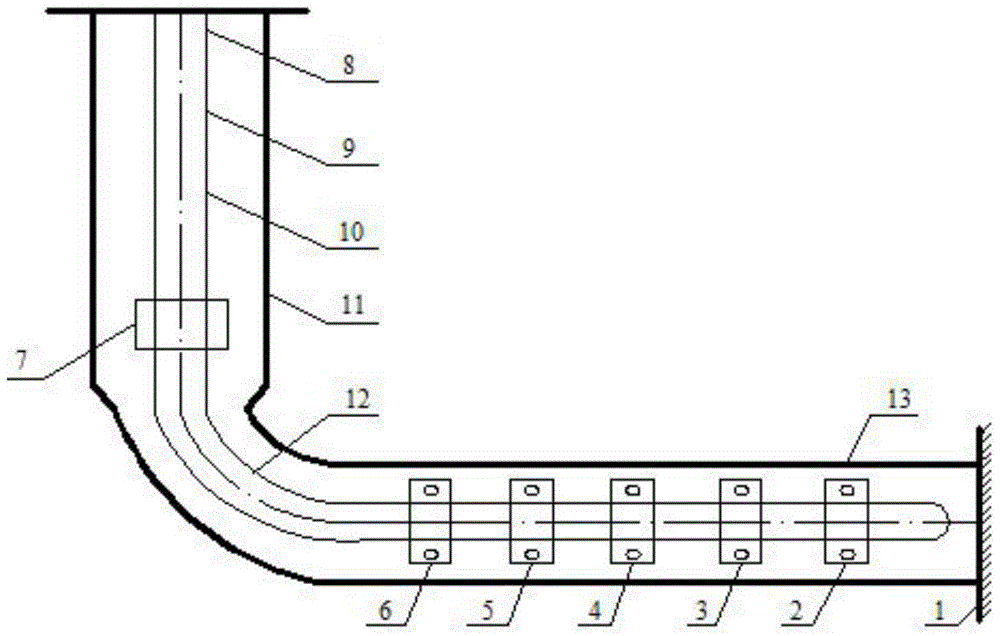

[0037] 1) Tubing string combination: Calculate the tensile stress safety factor of each tubing section of the hydraulic jet fracturing string according to the tensile strength of the tubing, the length of the tubing string, and the unit weight per meter, and calculate the tensile stress of the hydraulic jet fracturing string in the en...

Embodiment 2

[0049]Based on Example 1, in this embodiment, in step 1), safety factor of tensile stress=tensile strength of fracturing string / weight of string, weight of string=length of string×unit weight per meter.

[0050] Before the evaluation, it is necessary to determine the basic data of drilling and completion of each well required for the analysis

[0051] Combined with drilling and completion engineering data, according to each well's "Oil Testing (Gas) Geological Design" and "Oil Testing (Gas) Engineering Design" to obtain the well body structure data (including casing technical parameters), wellbore trajectory parameters (including well depth, well inclination and azimuth), logging data (oil (gas) bearing intervals, perforated intervals), formation prediction pressure and temperature and other data.

[0052] Determine the hydraulic jet fracturing string structure and construction data for each well required for analysis

[0053] Combined with well logging data, according to the...

Embodiment 3

[0076] Based on the above two embodiments, in this embodiment, the performance analysis and evaluation of the first section (4195m) of the jet fracturing string is carried out.

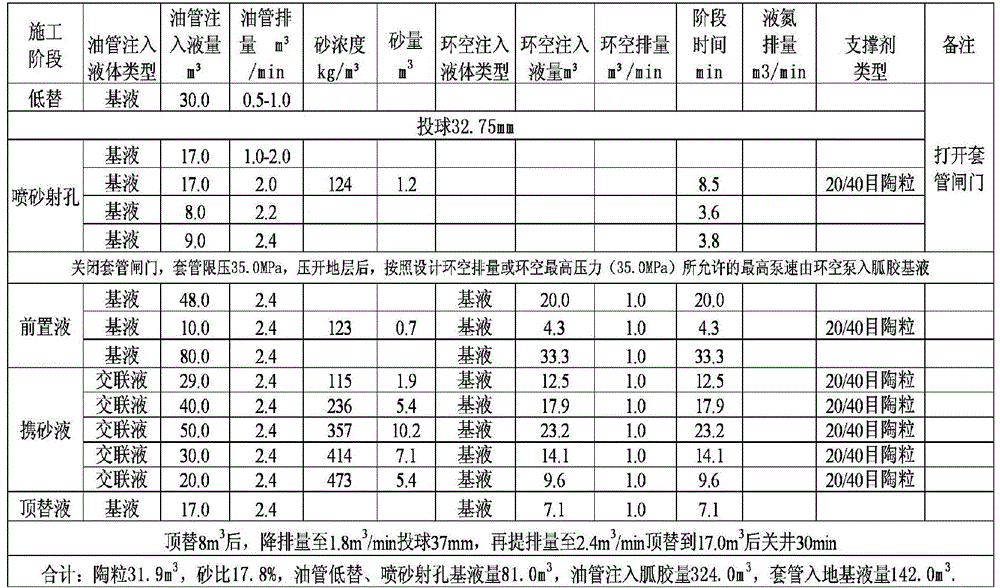

[0077] Table 1 is the jet fracturing pump injection schedule for the first section (4195m) of the well. Combined with the structural data of the fracturing string, the wellbore structure data, the properties of the liquid, etc., the performance of the first section (4195m) of the jet fracturing string is calculated. Analysis and evaluation:

[0078] Table 1. Jet fracturing pumping schedule for the first stage (4195m)

[0079]

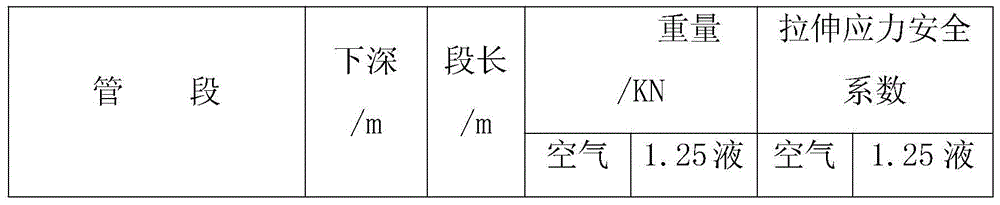

[0080] (1) String combination

[0081] It can be seen from Table 2 that the tensile stress safety factor of the whole well string in air is greater than 1.24, and the tensile stress safety factor in 1.25 liquid is greater than 1.47. Therefore, from the perspective of longitudinal tensile strength, the combination of pipe strings is basically reasonable, and the strength of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com