A potential energy conversion device

A conversion device, potential energy technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as large consumption of electric energy or thermal energy, and achieve unique measures, scientific and rational structure, and innovative ideas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

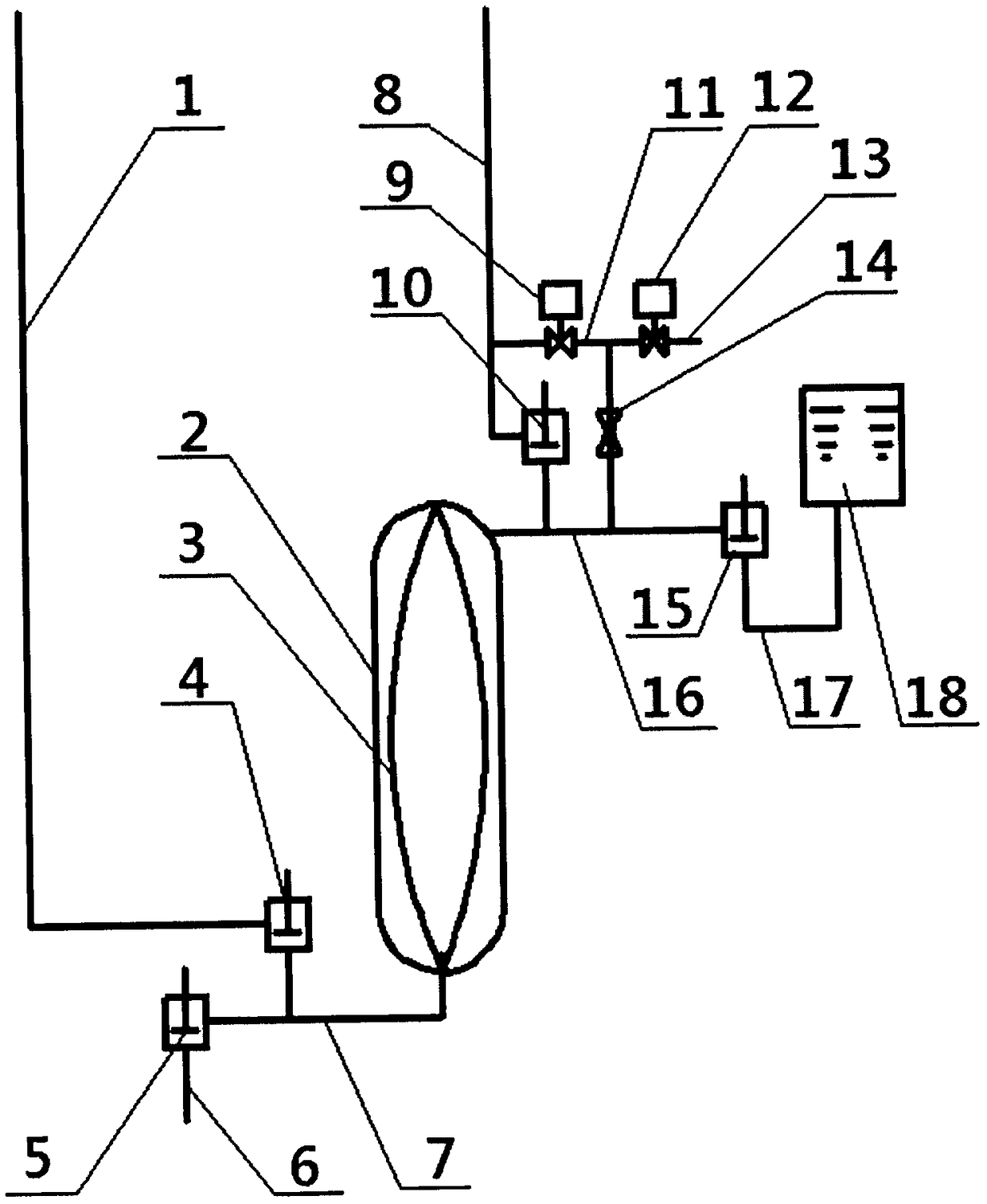

[0023] Under the control of the industrial control system, water, as the upward material, passes through the upward material feed valve (15) from the upward material buffer tank (18) along the pipeline four (17), and enters the pressure vessel (2) and the diaphragm (3) along the pipeline three (16). ), close the upstream material feed valve (15), open the pressure balance valve (9) between the upward material pipeline and the pressure vessel, and a small amount of upward material passes through the throttling buffer (14) along the three ( 16) Enter the pressure vessel (2), the internal pressure of the pressure vessel rises and reaches a pressure balance with the upward material pipeline, the industrial control system controls the downward material feed valve (4) to open, and the downward material with potential energy enters the pressure vessel (2) and the diaphragm In another space between (3), the pressure is transmitted to the upward material through the diaphragm (3), and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com