A plate shaping roller press

A rolling press and plate technology, applied in the direction of veneer press, plywood press, lamination, etc., can solve the problems of multiple production turnover sites, lower product qualification rate, and long production cycle, so as to shorten the production cycle and improve the quality of finished products. The effect of low machine cost and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

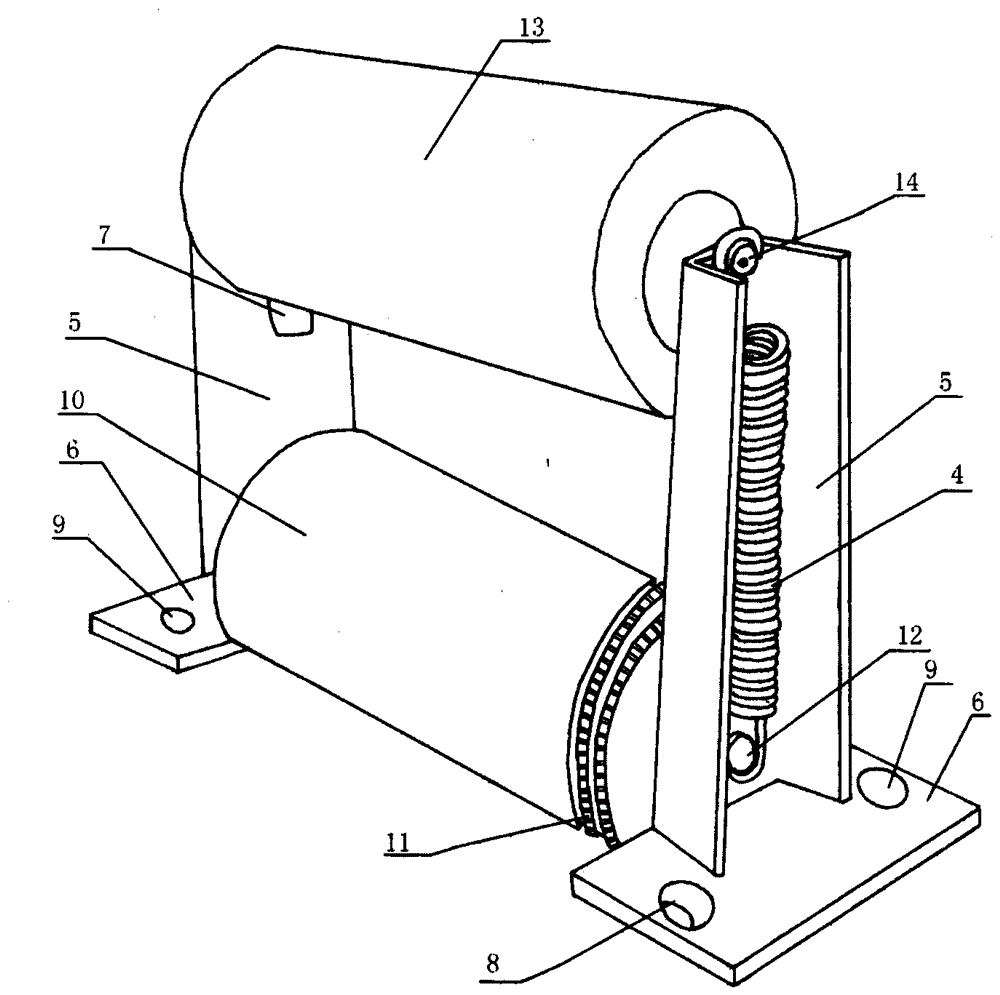

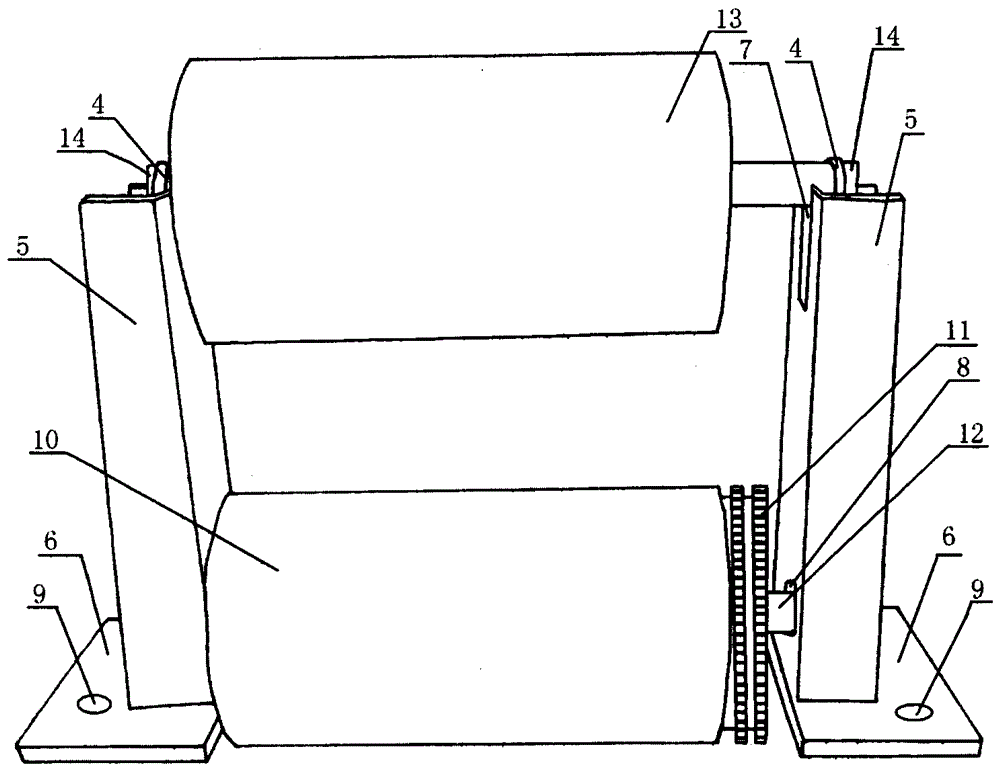

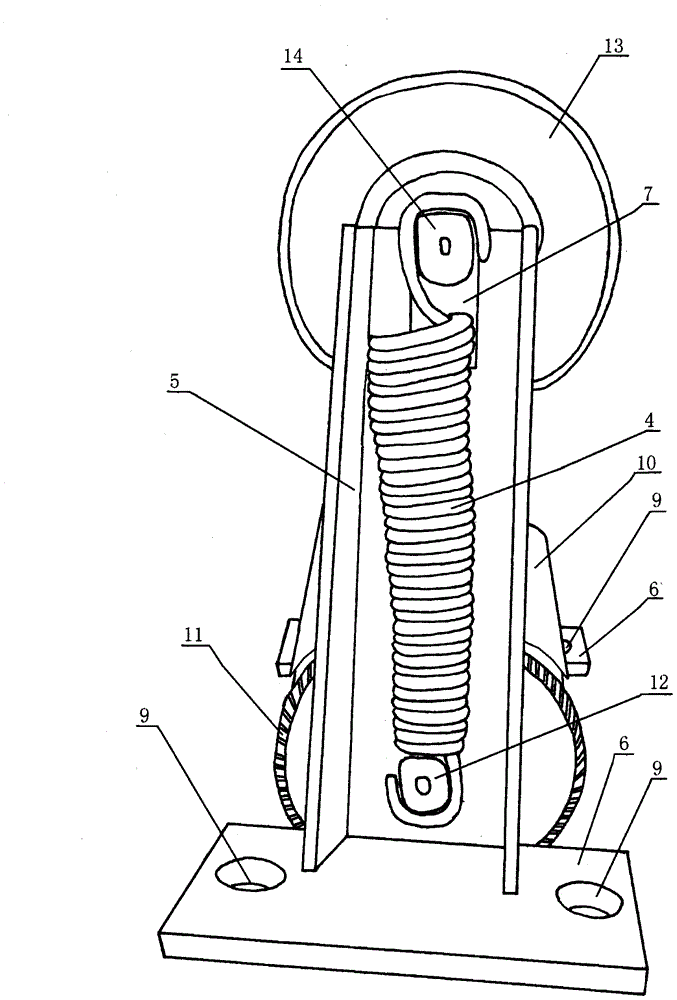

[0039] Now in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0040] The invention is composed of a body frame (1), a driving pressure roller (2), an auxiliary dynamic pressure roller (3) and a spring (4).

[0041] figure 1 Shown is the structural representation of the present invention. Among them, 4 is the spring (4), 5 is the frame body (5), 6 is the frame foot (6), 7 is a liftable axis (7) provided on the upper part of the frame body, and 8 is the lower part of the frame body. A shaft hole (8) that is provided with, 9 is the fixed screw hole (9) that is respectively provided with on the left and right sides of frame pin, and 10 is effective working roller one (10), and 11 is transmission sprocket wheel (11), and 12 It is shaft core one (12), 13 is effective working roller two (13), and 14 is shaft core two (14).

[0042] figure 2Shown is also a structural schematic diagram of the present invention. 4 is a spring (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com