A pure long straw bagging machine used for edible fungus cultivation

An edible fungus and bagging machine technology, applied in application, horticulture, botany equipment and methods, etc., can solve the problems of low cutting or crushing work efficiency, uneven distribution of raw materials, low utilization rate of fungus bags, etc. Reasonable collocation layout, scientific and reasonable structure composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

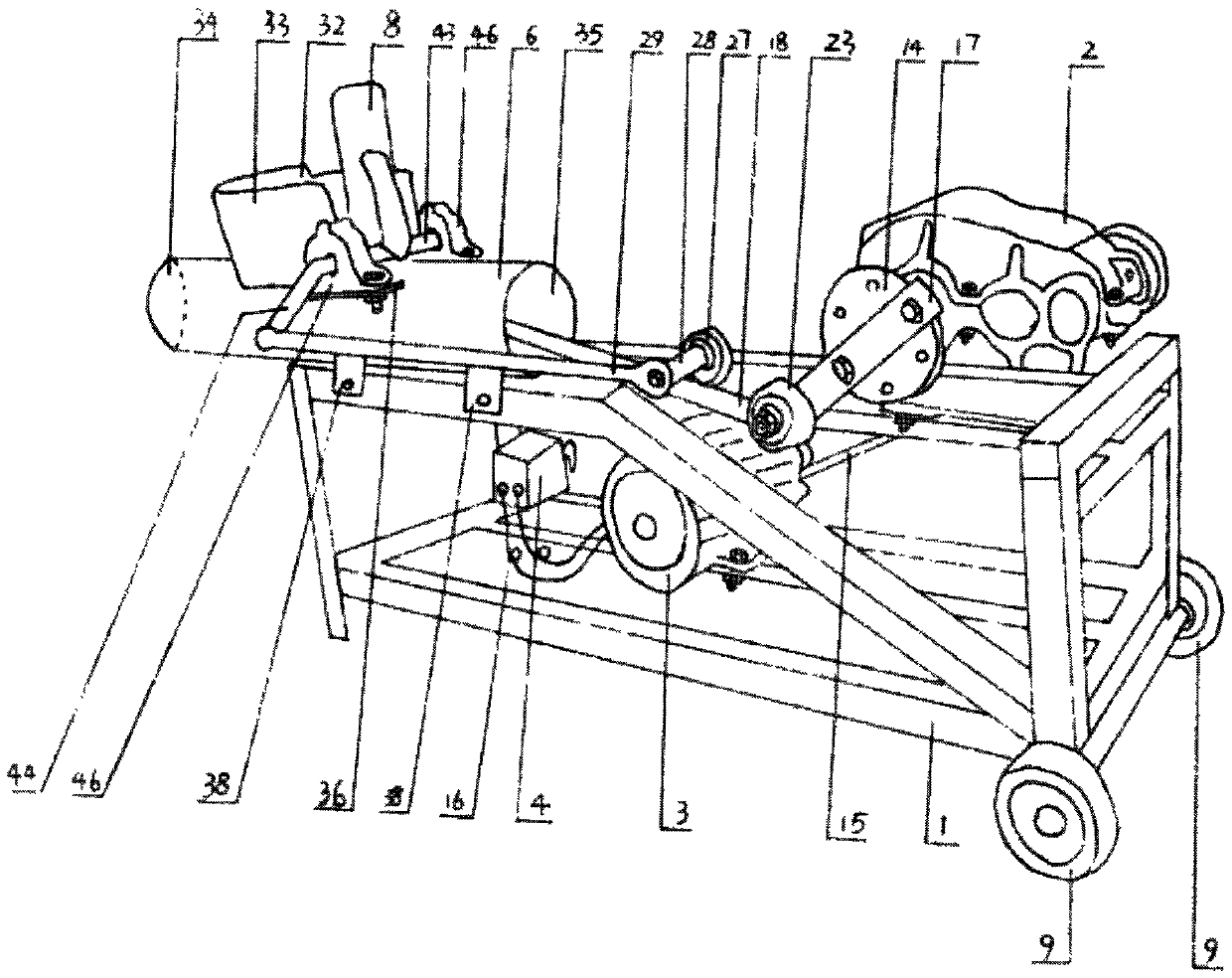

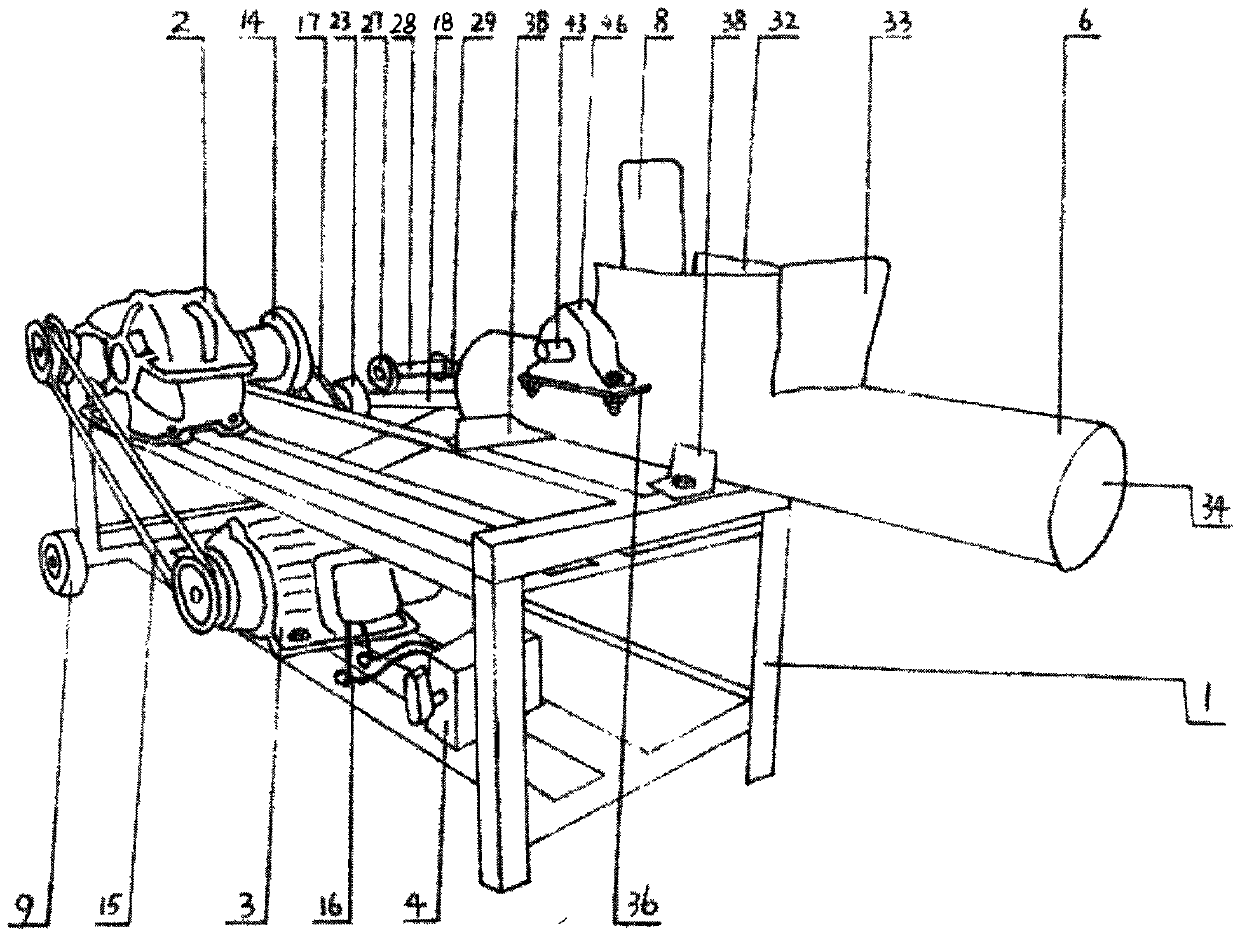

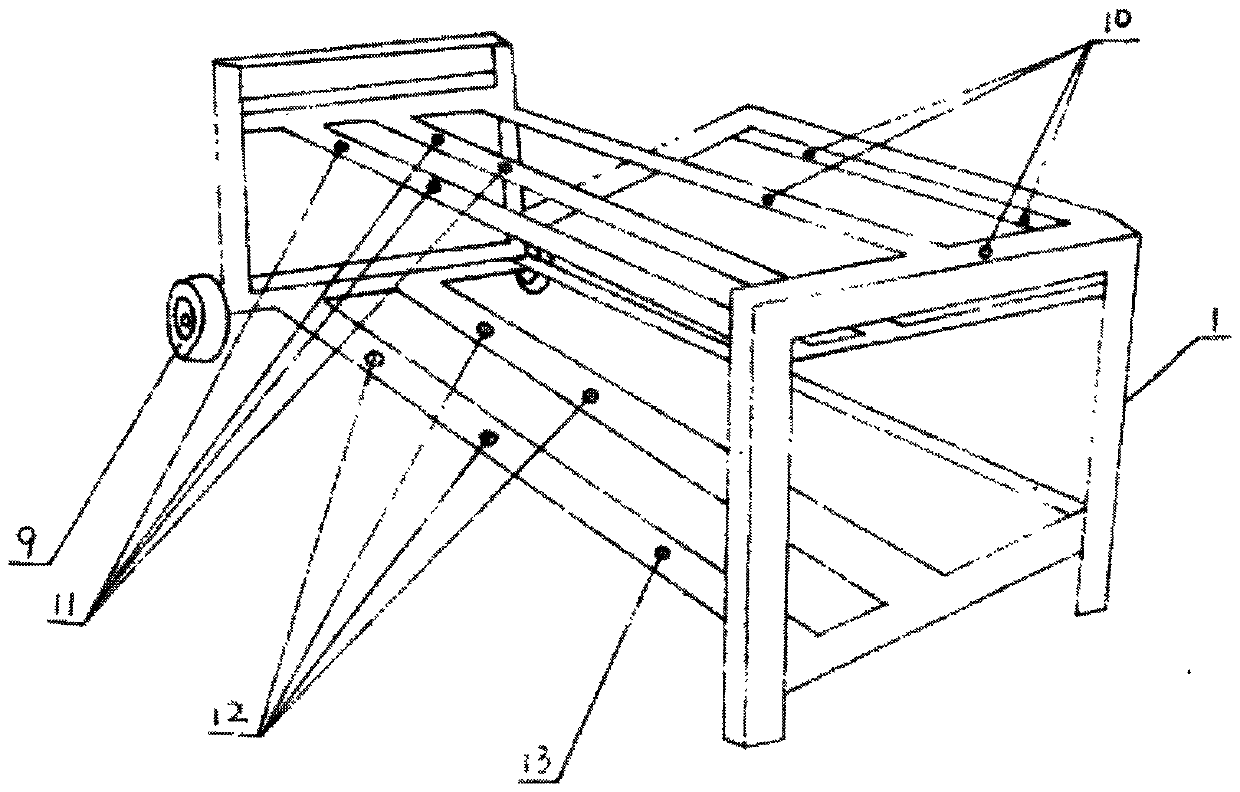

[0041] Now in conjunction with accompanying drawing, the present invention is described in detail:

[0042] The structure of the present invention is composed of a body frame (1), a gearbox (2), a motor (3), a motor switch (4), a linkage pull rod (5), an inlet and outlet barrel path (6), a feeding sleeve (7), The binder plate (8) is composed of; wherein, the gearbox (2) is arranged on the middle rear end of the body frame (1), the motor (3) is arranged on the lower middle part of the body frame (1), and the motor switch (4) is It is arranged at the front end of the lower layer of the body frame (1), and the inlet and outlet channel (6) is arranged at the front end of the upper layer of the body frame (1); the linkage pull rod (5) is connected with the feeding sleeve (7) and the pressure plate (8) at the same time ), the feeding sleeve (7) is placed in the inlet and outlet channel (6), and the pressure plate (8) is placed next to the feed port of the inlet and outlet channel (6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com