Method for obtaining variable toe-in curve of wheels

A toe-in and curve technology, applied in the field of automobile chassis performance test, to achieve the effect of easy installation and disassembly, increase the adjustable range and save test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

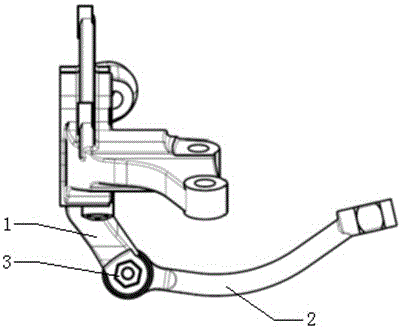

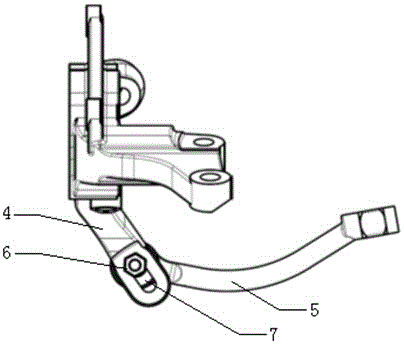

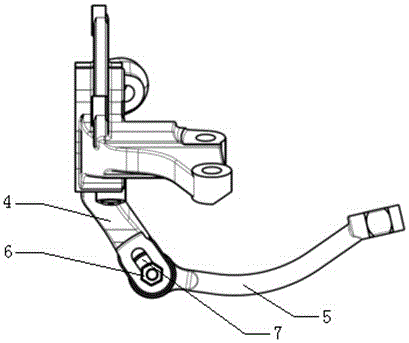

[0018] see figure 2 or image 3 As shown, a method for obtaining the variable toe curve of a wheel, the steering knuckle sample used in this method includes a steering knuckle arm 4, a steering tie rod 5, a bolt 6 connecting the steering knuckle arm and the steering tie rod, and the steering knuckle arm 4 Bolt hole 7 on the top is oval; The method comprises the following steps:

[0019] The first step is to measure the basic static parameters of the four-wheel alignment: first adjust the connection position of the steering knuckle arm 4 and the steering tie rod 5 to the upper end of the bolt hole 7, and lock the steering knuckle arm 4 and the steering tie rod 5, as figure 2 As shown, then install it on the vehicle, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com