Coating rapid dispersion or mixing multi-purpose tester test bottle fixture

A technology of fixing devices and test bottles, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as failure, missing experiments, waste efficiency, etc., and achieve the effect of cost saving and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

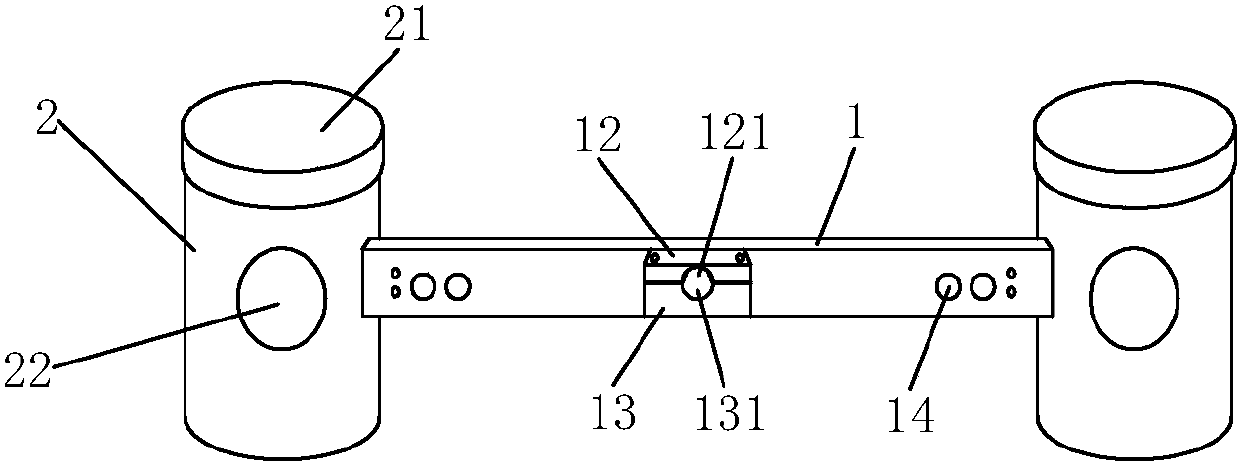

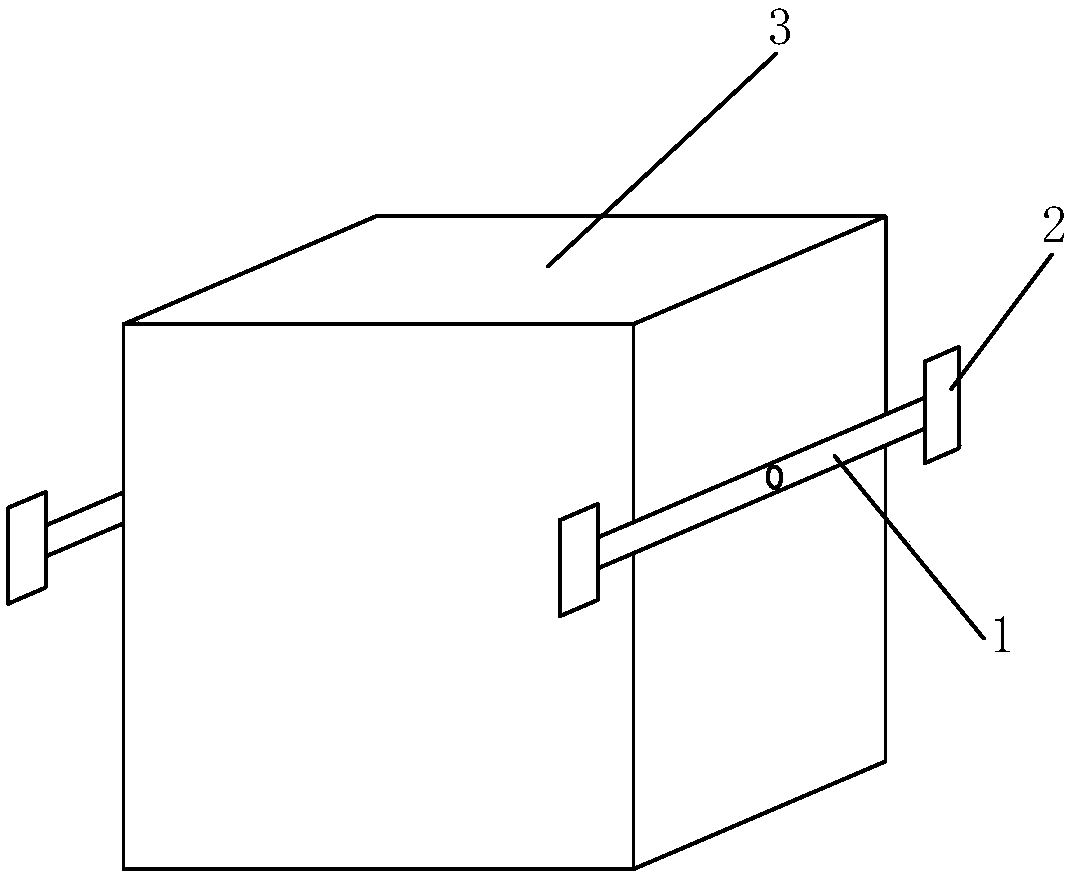

[0021] A test bottle fixing device for a multi-purpose tester for rapid dispersion or mixing of paint, comprising a connecting rod 1, and the two ends of the connecting rod 1 are respectively equipped with a test bottle fixing device, and the test bottle fixing device is open at the upper end, closed at the lower end, and hollow The test bottle clamp body 2 of cylindrical structure, the open end of the upper end of the test bottle clamp body 2 is provided with a clamp body cover 21 that can be opened and closed, and the connecting rod 1 is quickly dispersed or mixed with the paint in a detachable manner for multi-purpose testing The active axis of the device is connected. The side wall of the test bottle clamp body 2 is provided with a through hole, through which the separation of the samples in the test bottle can be observed, and the test bottle can be easily pushed out through the through hole to facilitate taking the test bottle. The middle part of the clip body cover 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com