Contact with fixed fracture and having short-circuit current breaking capability and vacuum arc extinguishing chamber

A short-circuit current and contact technology, used in high-voltage/large-current switches, electrical switches, high-voltage air circuit breakers, etc., can solve the problems of complex vacuum interrupter structure, lack of vacuum arc composite magnetic field control, etc., and achieve excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

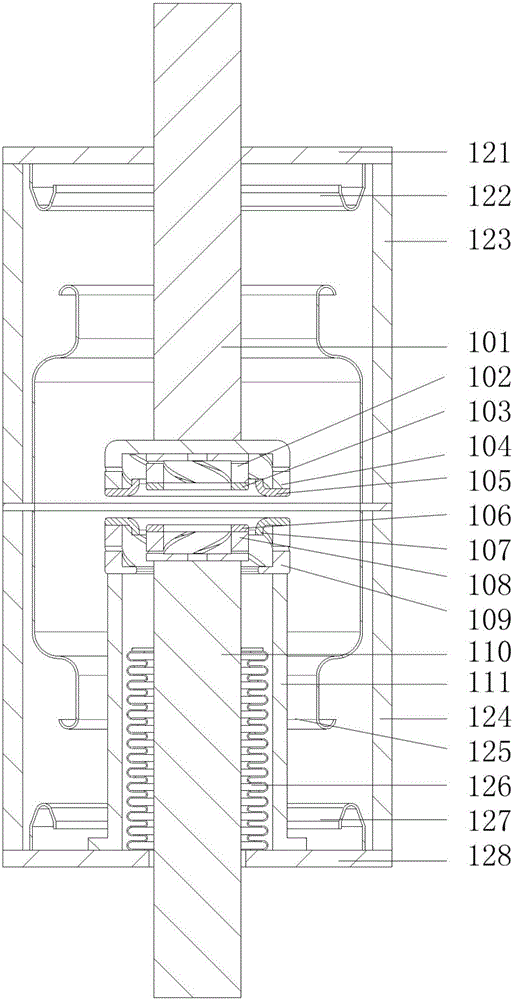

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

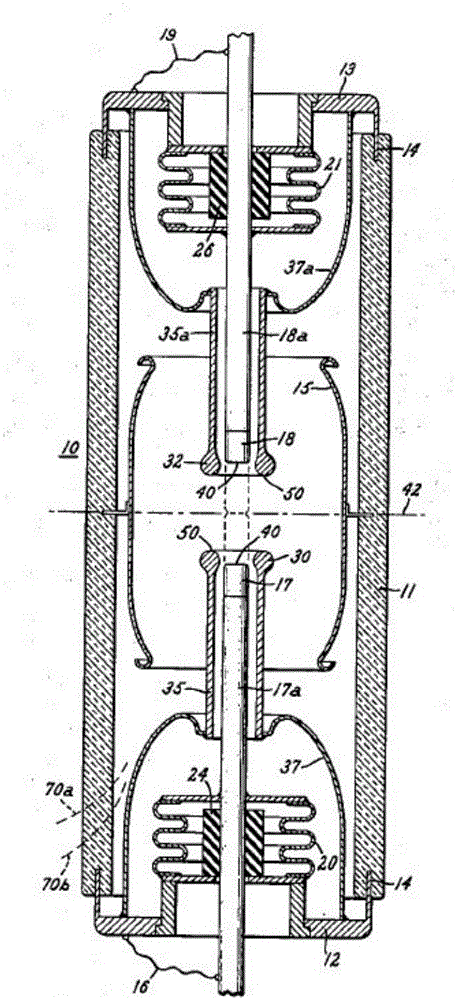

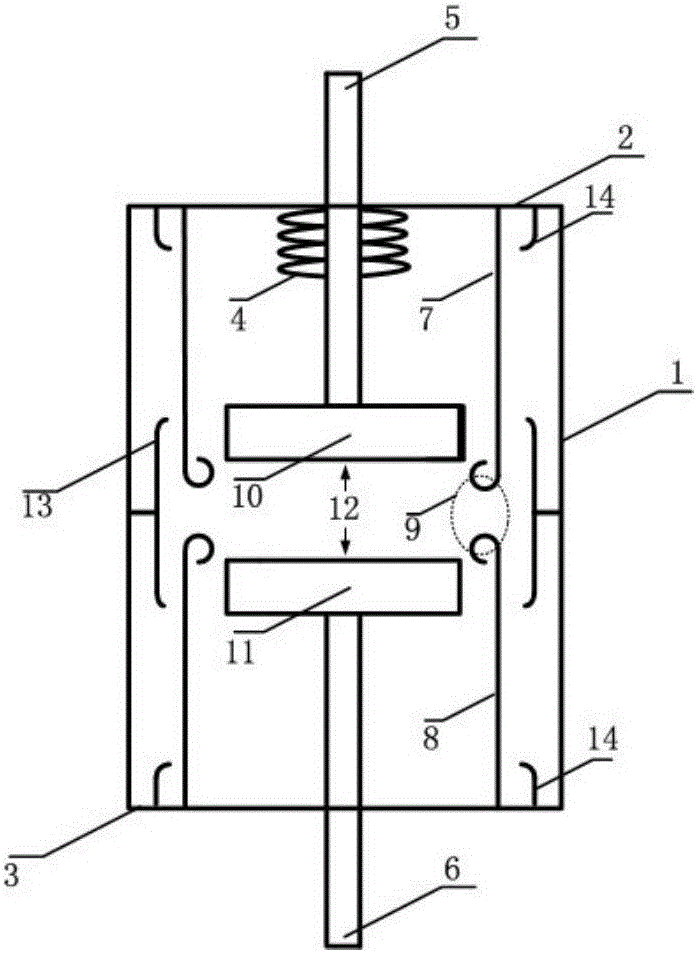

[0031] The present invention has a contact with a fixed fracture and short-circuit current breaking capability, including a static side structure part and a moving side structure part. The static side structure part includes a static side conductive rod 101, and a static The side large-diameter magnetic field contact 104, the static-side large-diameter contact material 105 welded to the lower end of the static-side large-diameter magnetic field contact 104, the static-side small-diameter magnetic field contact 102 welded to the inner bottom surface of the static-side large-diameter magnetic field contact 104 The lower end of the static-side small-diameter magnetic field contact 102 is welded with a static-side small-diameter contact material 103; the static-side small-diameter magnetic field contact 102 and the welded static-side small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com