Material distribution device and vibrating screening machine

A material distribution device and vibrating screen technology, which can be used in filter screens, solid separation, chemical instruments and methods, etc., can solve the problems of processing cost and processing time increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

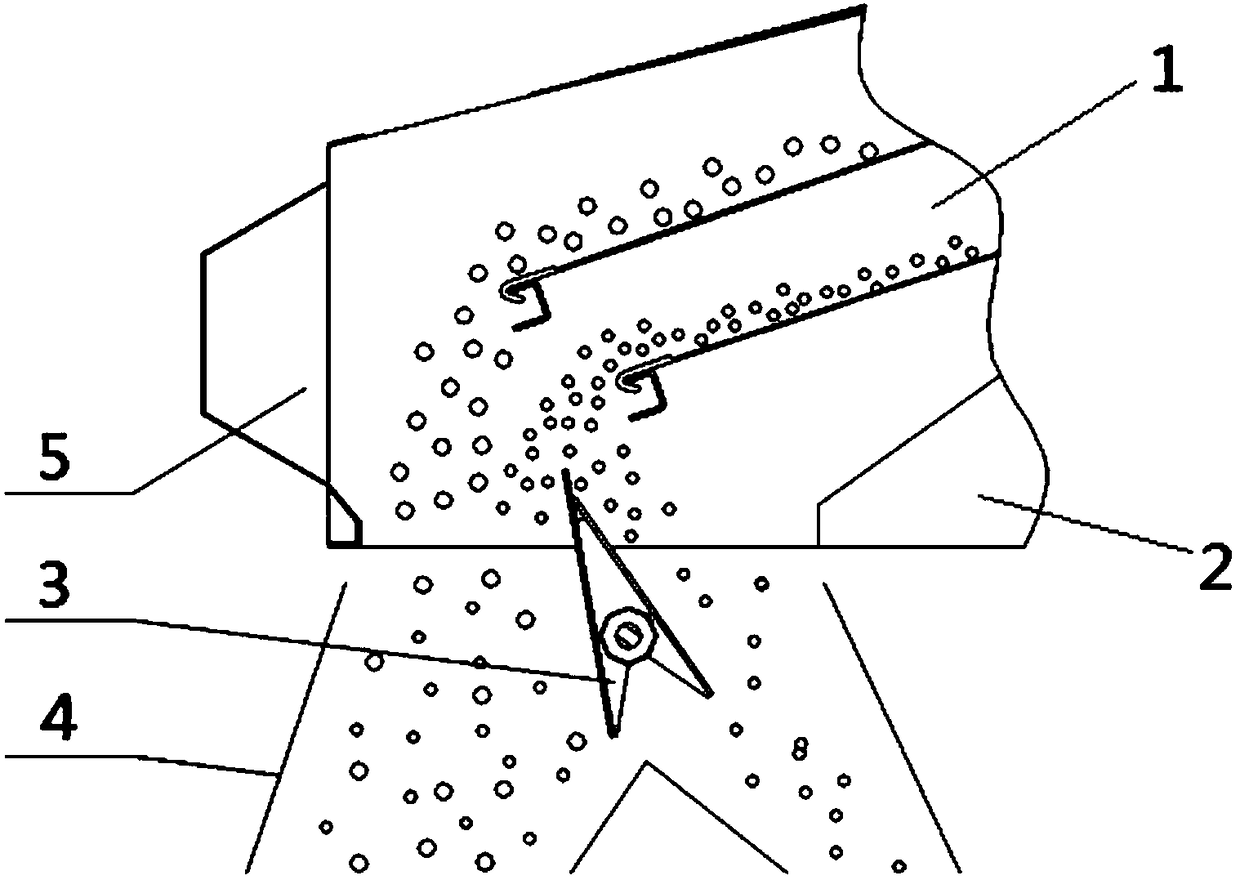

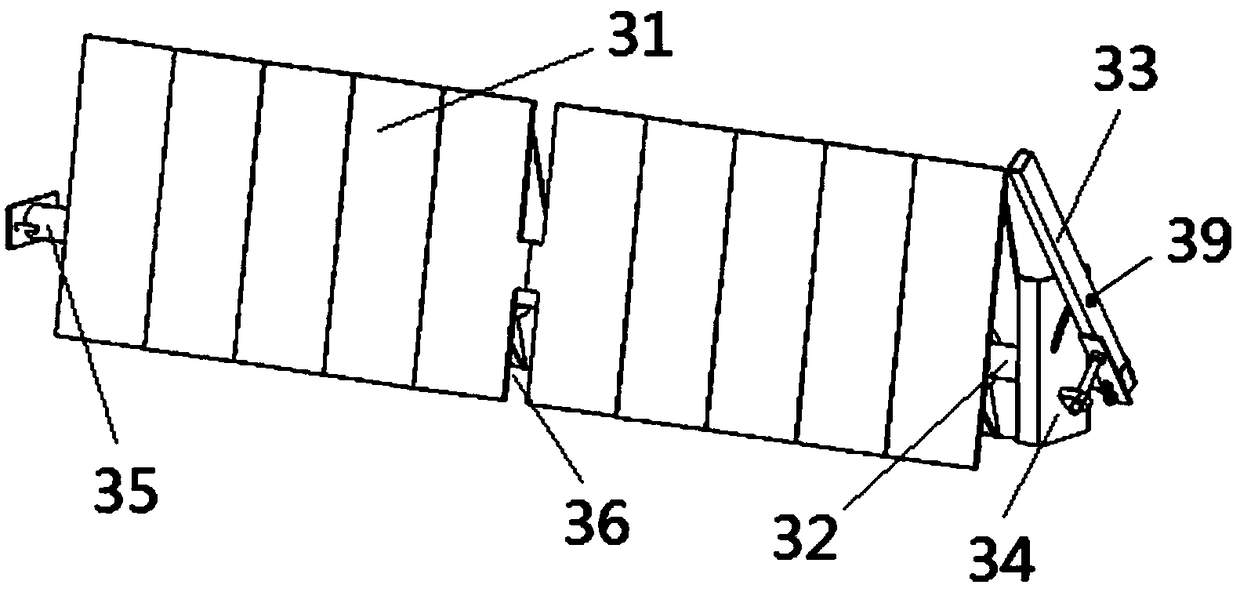

[0026] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0027] After the existing vibrating screening machine screens the material into materials of different particle sizes, it is directly discharged through the independent channel of the guide groove, so the obtained materials are each of a single particle size. If the mixed materials are required, they need to pass through other Proportional mixing of these single particle size materials is carried out by advanced transportation equipment.

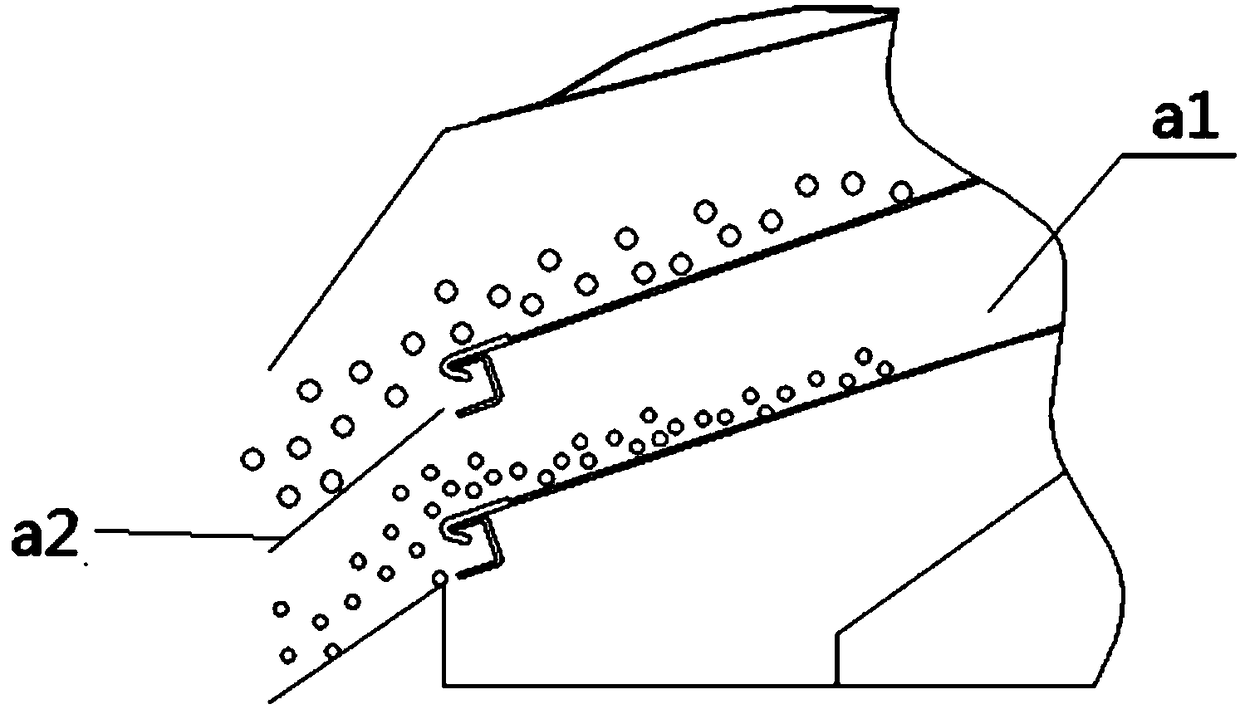

[0028] The present invention adds a material distributing device to the vibrating screening machine, and uses the material distributing plate in the material distributing device to distribute the screened materials, so that the screened materials with different particle sizes can be divided according to the preset ratio. Mixing is carried out, and the angle of the material distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com