Pressure-resistant single-layer two-color hose and preparation method thereof

A two-color tube and single-layer tube technology, which is applied to tubular articles, other household appliances, household appliances, etc., can solve the problems of high equipment cost, delamination of PVC hoses, and leakage of liquid from cracks in the pipe layers, and reduce the difficulty of the preparation process. , The effect of reducing accident rate and equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

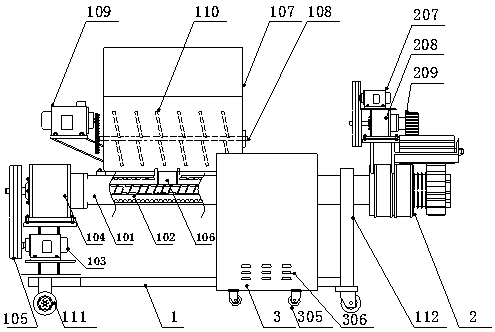

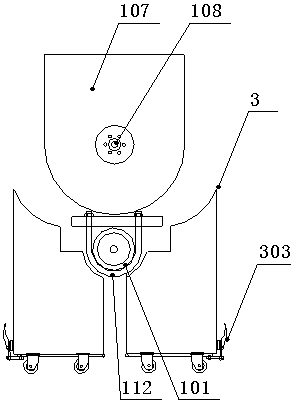

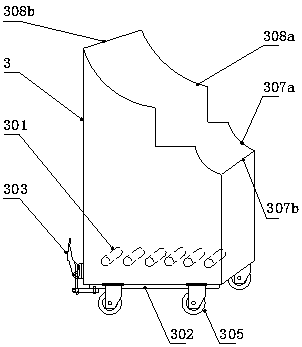

Method used

Image

Examples

Embodiment 1

[0062] (1) After pulverizing 80 parts of polyvinyl chloride and 5 parts of chemical fiber in the bottom raw material, put them into the hopper of the extruder, heat and dry at 90°C for 0.5h, and control the speed of the stirring device in the hopper to 30r / min;

[0063] (2) After the drying is completed, 5 parts of epoxidized soybean oil and dioctyl phthalate are added to the hopper, wherein dioctyl phthalate accounts for 5% by weight of the plasticizer total amount, stir After uniformity, the temperature of the hopper and the screw at the feed inlet is directly raised from the drying temperature to the melting temperature of 150°C, and the raw material is heated to a molten state and finally extruded through the screw and machine head;

[0064] (3) After the strip-shaped melt extruded by the extruder in step (2) is water-cooled, dried, and pulverized, it enters two extruders successively to exhaust and extrude respectively in a molten state. Said extruder adopts single-laye...

Embodiment 2

[0068] (1) After pulverizing 120 parts of polyvinyl chloride and 30 parts of chemical fiber in the bottom raw material, put them into the hopper of the extruder, heat and dry at 130°C for 2 hours, and control the speed of the stirring device in the hopper to 180r / min ;

[0069] (2) After the drying is completed, add 40 parts of epoxidized soybean oil and dibutyl ester to the hopper, wherein the weight percentage of dibutyl ester to the total amount of plasticizer is 15%, and after stirring evenly, put the hopper and the feed The screw at the mouth is directly heated from the drying temperature to the melting temperature of 160°C, and the raw material is heated to a molten state and finally extruded through the screw and the machine head;

[0070] (3) After the strip-shaped melt extruded by the extruder in step (2) is water-cooled, dried, and pulverized, it enters two extruders successively to exhaust and extrude respectively in a molten state. Said extruder adopts single-laye...

Embodiment 3

[0074] (1) After crushing 90 parts of polyvinyl chloride and 10 parts of chemical fiber in the bottom raw material, put them into the hopper of the extruder, heat and dry at 100°C for 1 hour, and control the speed of the stirring device in the hopper to 60r / min ;

[0075] (2) After the drying is completed, add 10 parts of epoxidized soybean oil and dibutyl phthalate to the hopper, wherein dibutyl phthalate accounts for 10% by weight of the plasticizer total amount, stir After uniformity, the hopper and the screw at the feed inlet are directly heated from the drying temperature to the melting temperature of 155°C, and the raw material is heated to a molten state and finally extruded through the screw and the machine head;

[0076] (3) After the strip-shaped melt extruded by the extruder in step (2) is water-cooled, dried, and pulverized, it enters two extruders successively to exhaust and extrude respectively in a molten state. Said extruder adopts single-layer two-color tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com