rtm method with intermediate fiber layer

A technology of intermediate fibers and fiber segments, which is applied in the field of manufacturing fiber composite components, can solve problems such as high mold costs and production costs, and achieve the effect of improving process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

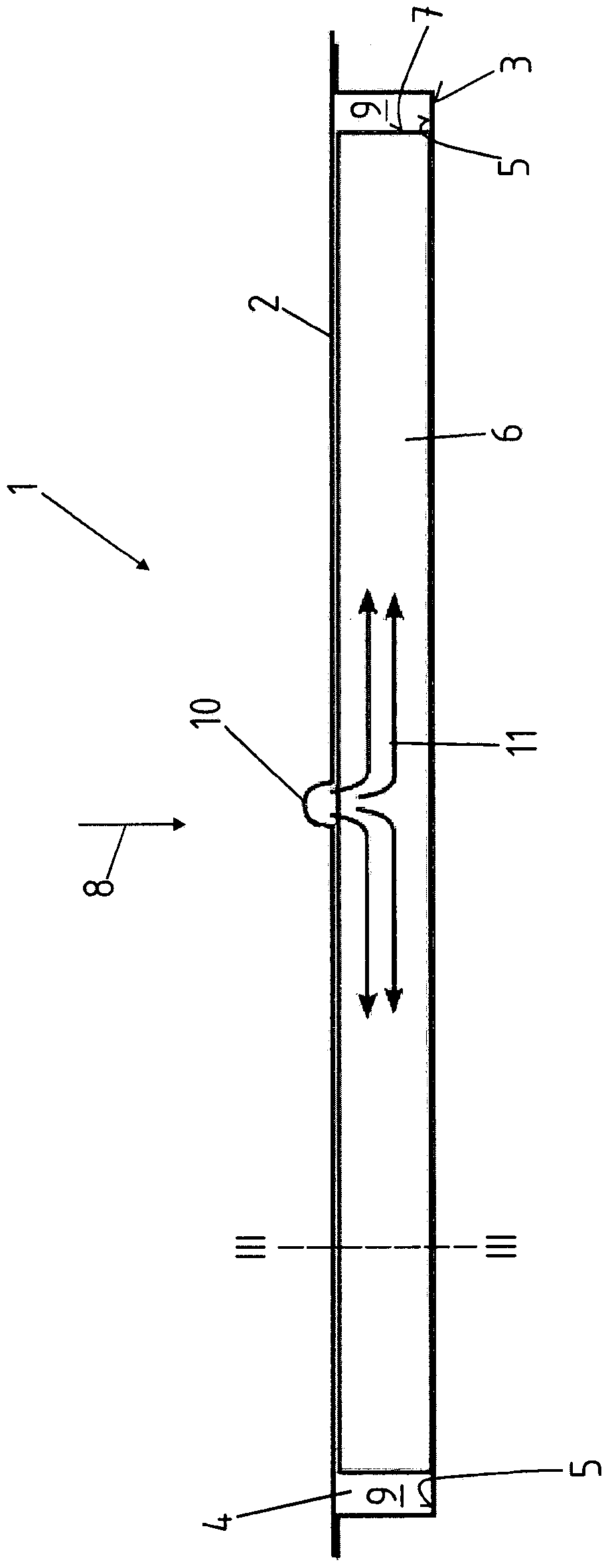

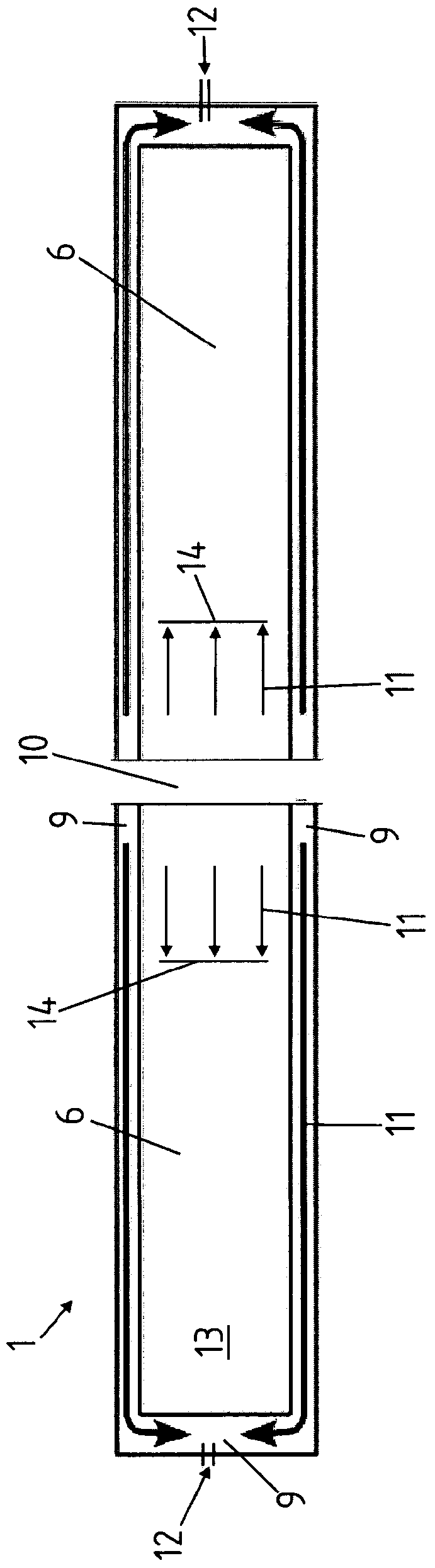

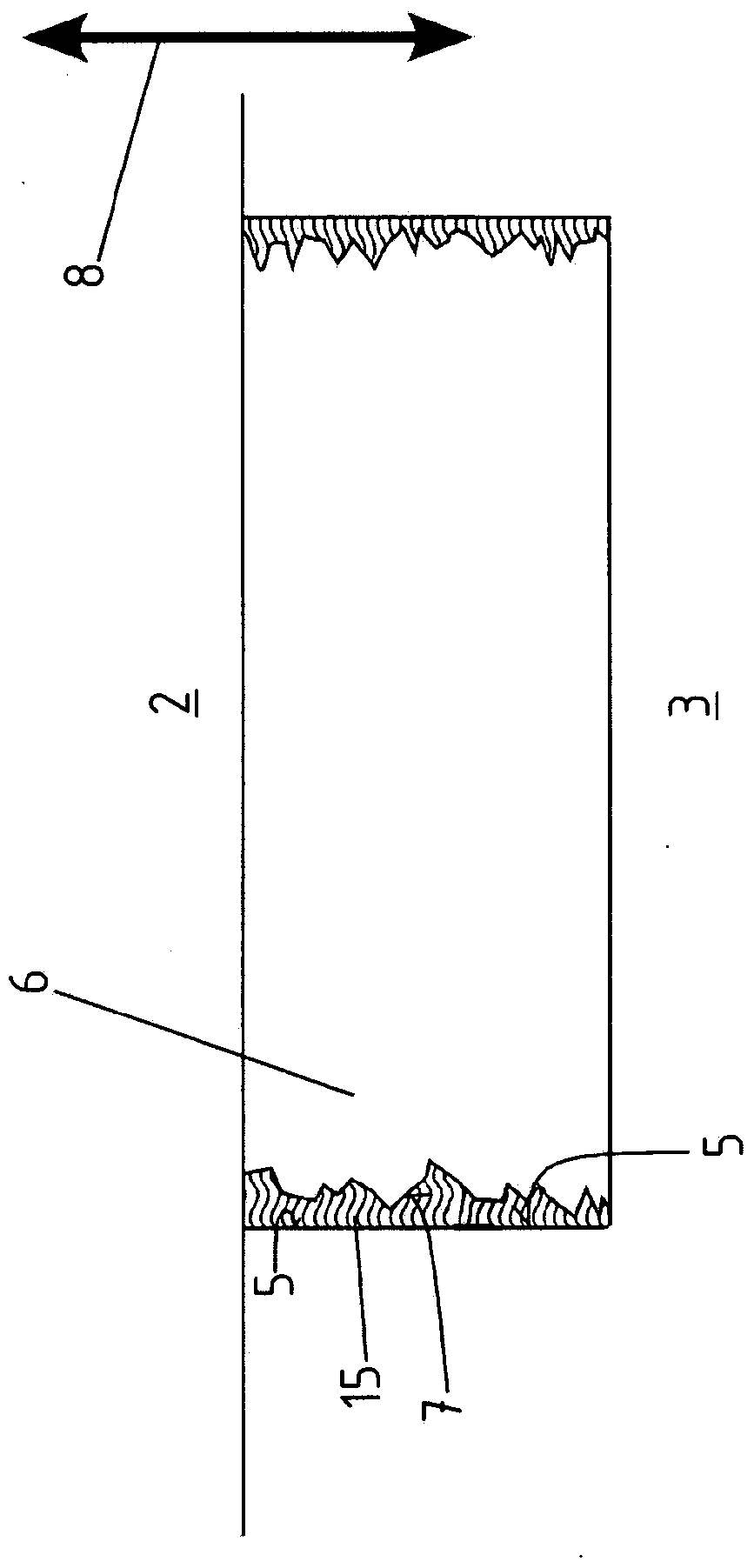

[0038] figure 1 A schematic mold 1 is shown with an upper mold 2 and a lower mold 3 , which is closed and thus has a mold cavity 4 . An inner surface 5 is formed in the mold cavity 4 . Furthermore, the fibrous material blank 6 is introduced into the mold cavity 4, wherein the outer surface 7 of the fibrous material blank 6 is in abutting contact with the inner surface 5 of the mold cavity 4, in particular substantially transversely to the extrusion stroke. In the area oriented in direction 8. However, a clearance space 9 remains, in which the outer surface 7 of the fiber material blank 6 does not come into abutting contact with the inner surface 5 of the mold cavity 4 . In the central region, resin injection openings are arranged in the form of strip gates 10 , so that the resin injected through these openings flows through the fiber material blank 6 . in press figure 2 Clearly visible in the top view of , the vacated space 9 is not only as in figure 1 remains equally on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com