Rail device with material positioning mechanism

A material positioning and track technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of complex positioning mechanism structure, increase equipment failures, affect production work and other problems, achieve good positioning effect, reduce equipment failures, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

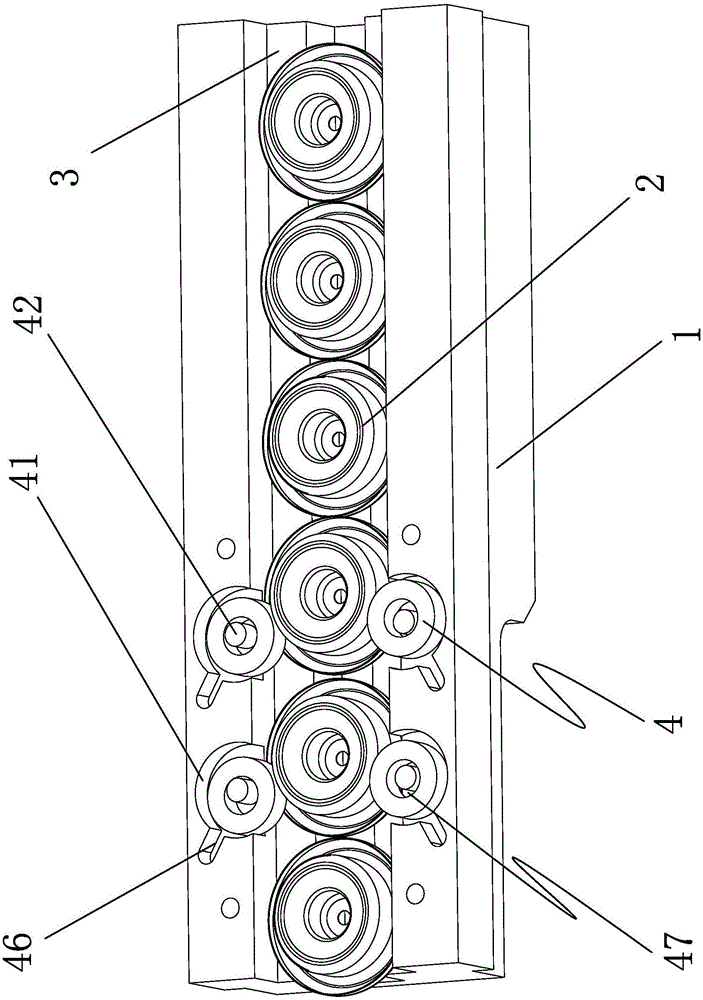

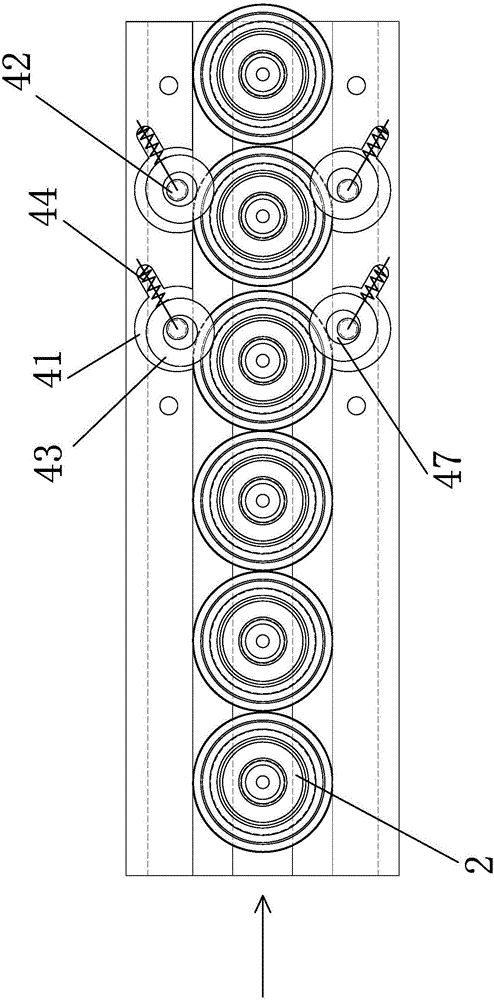

[0023] The first embodiment of the movable roller mechanism 4 in the present invention includes a mounting groove 41 arranged on the track seat 1, a pin shaft 42 is arranged in the mounting groove 41, and a There is a roller 43 that can swing relative to the pin shaft 42 , and an elastic member 44 that can push the roller 43 to the material 2 is arranged in the installation groove 41 .

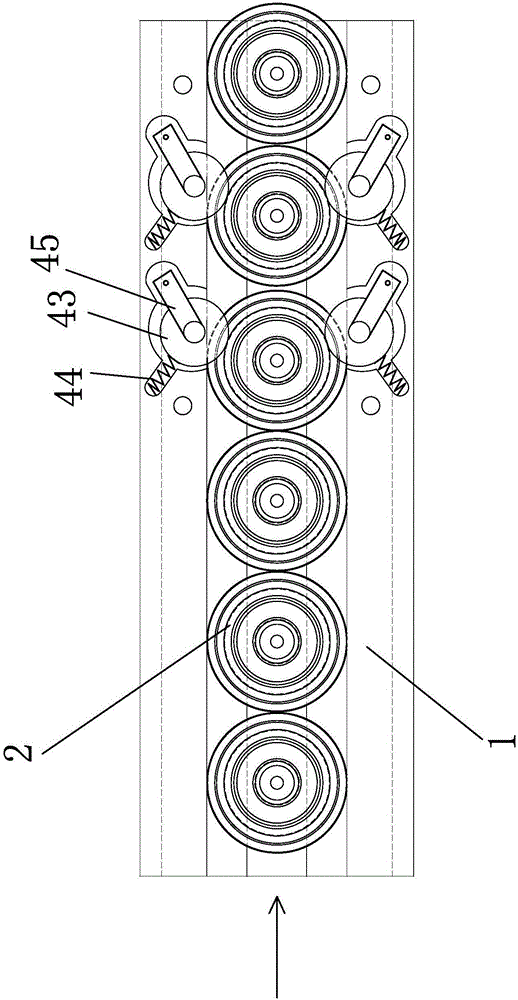

[0024] The second embodiment of the movable roller mechanism 4 described in the present invention includes a mounting groove 41 arranged on the track seat 1, a swing arm 45 is arranged in the mounting groove 41, and one end of the swing arm 45 is connected to the mounting In the groove 41 , a roller 43 is arranged on the other end of the swing arm 45 , and an elastic member 44 capable of pushing the roller 43 to the material 2 is arranged in the installation groove 41 .

[0025] In the present invention, the track seat 1 is provided with a connection groove 46 communicating with the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com