Transport mechanism

A technology for transporting materials and receiving troughs, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., and can solve problems such as vibration or falling of product parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

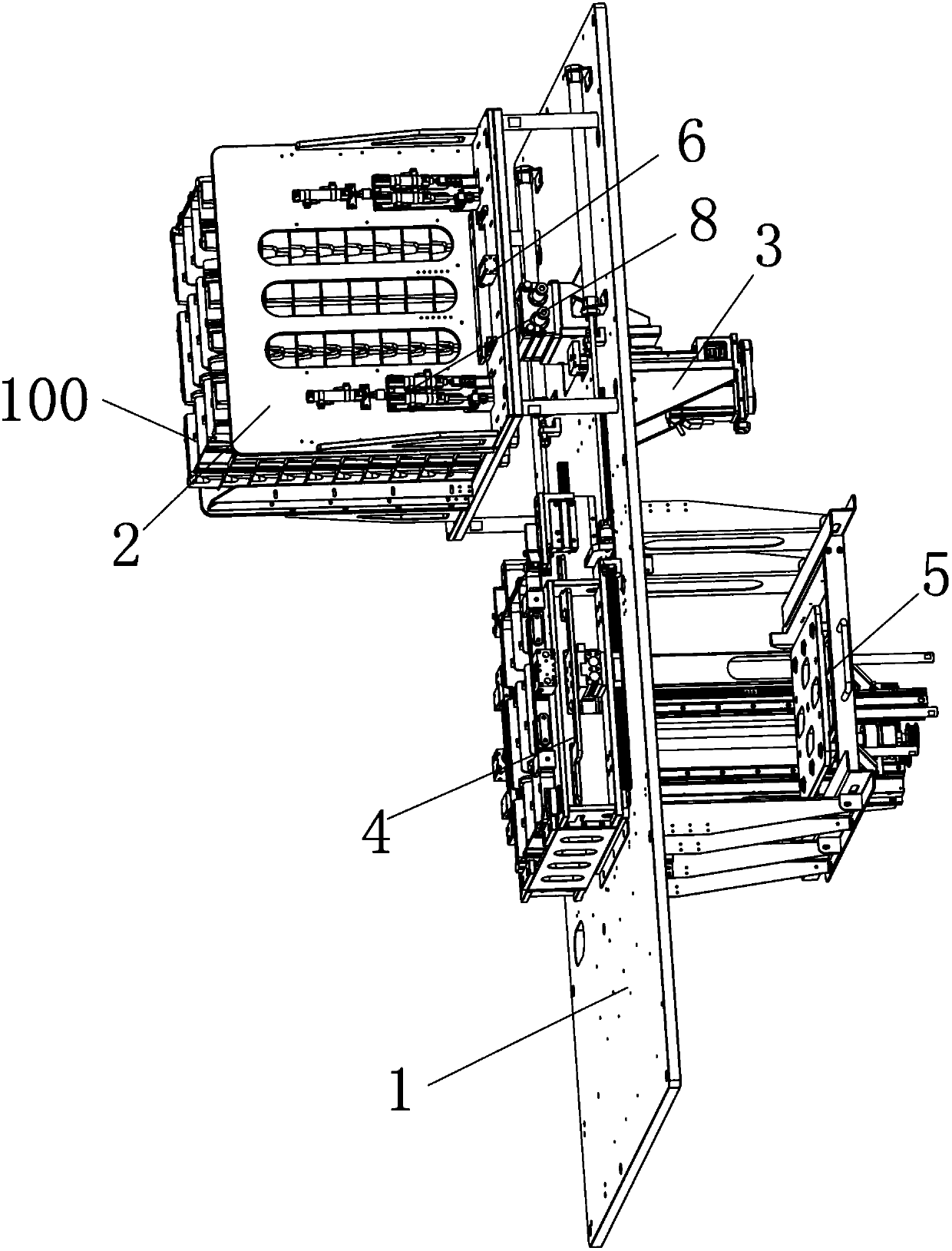

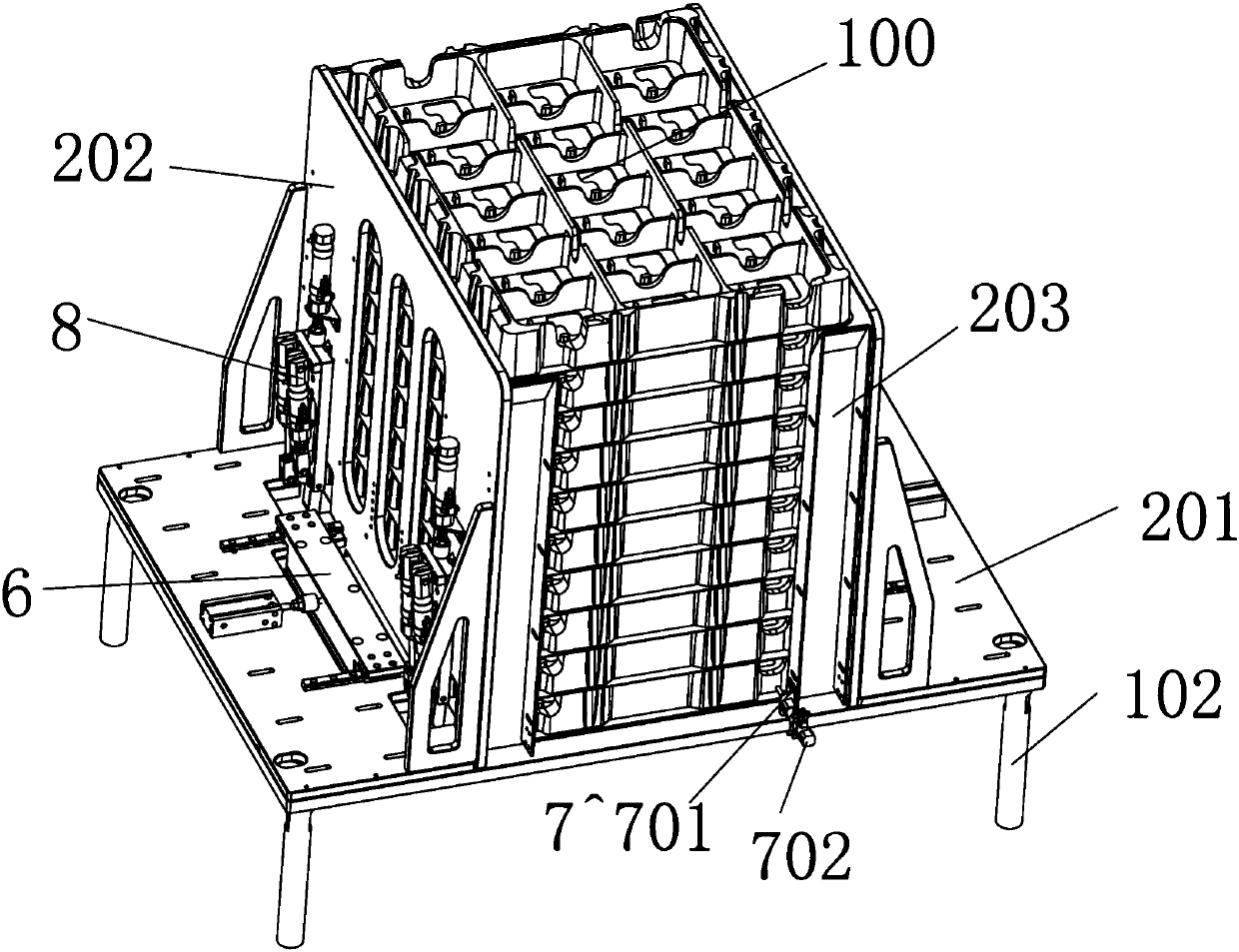

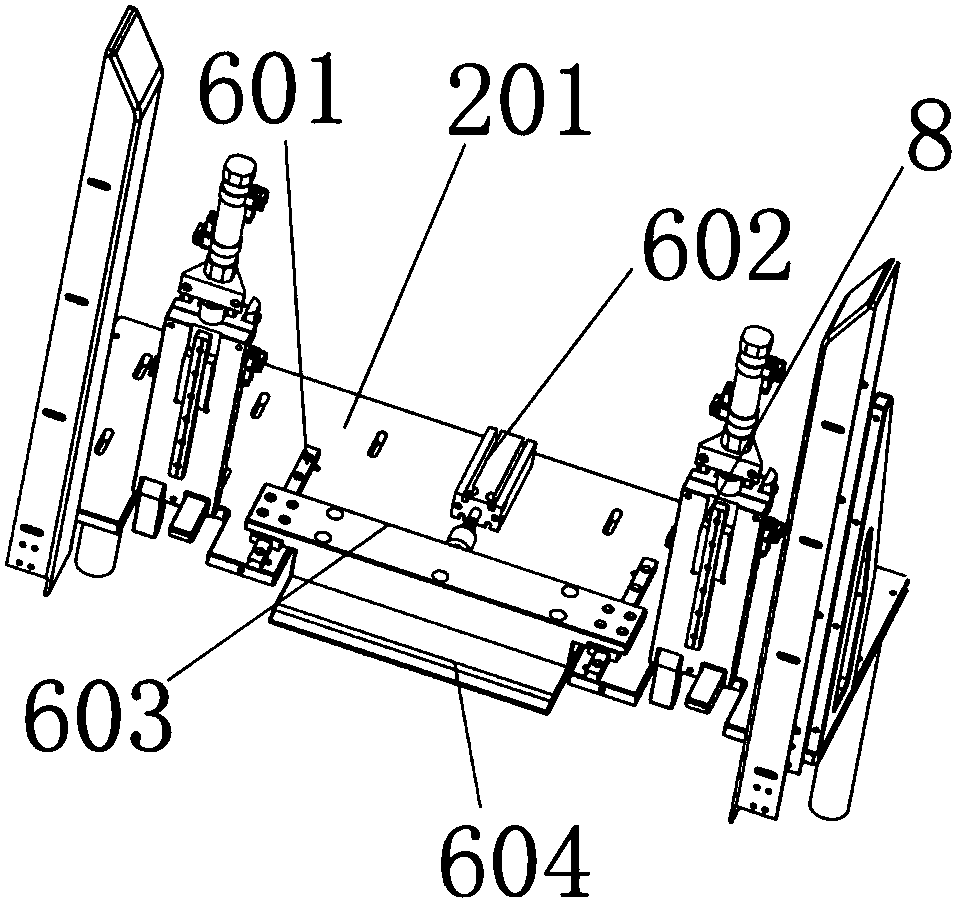

[0039] refer to Figure 1-Figure 11 The present embodiment provides a feeding device, including a bottom plate 1 provided with a receiving tank 101, a material storage mechanism 2 fixed at one end of the bottom plate 1 through a pillar 102, a bottom plate 1 fixed at the bottom end of the storage mechanism 2, and The correction mechanism 3 corresponding to the storage mechanism 2, the transport mechanism 4 arranged on the bottom plate 1 corresponding to the correction mechanism 3 and used in conjunction with the receiving tank 101, and the lower end surface of the bottom plate 1 and the receiving mechanism 5 corresponding to the receiving tank 101;

[0040] And the receiving trough 101 is provided with a blanking guide plate 103;

[0041] The material storage mechanism 2 includes a material storage bottom plate 201 fixedly arranged on the pillar 102 and having a discharge chute (not marked in the figure), and a storage base 201 fixedly arranged on the left and right sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com