Double-plate pay-off rack with mechanical arm sterilizing system

A technology of robotic arms and pay-off racks, applied in chemistry, conveying filamentous materials, thin material processing, etc., can solve problems such as power supply in places where it is difficult to ensure use, pay-off racks do not have disinfection functions, and magnetic powder motors are not suitable. , to achieve the effect of compact structure, easy popularization and application, and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

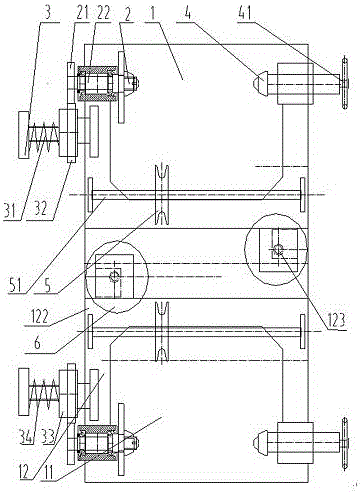

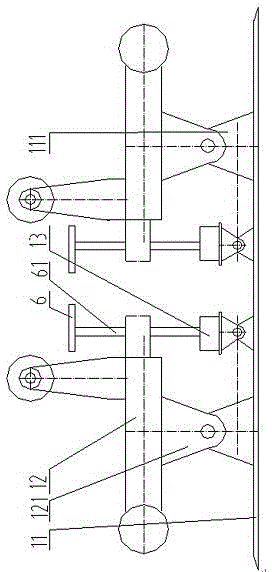

[0013] Such as figure 1 As shown, the present invention includes a frame body 1 and two pay-off devices, and the two pay-off devices are installed on the frame body 1; the pay-off device includes a thimble 4, a pay-off dial 2, a tension adjustment hand wheel 3 and a guide wheel 5. The tension adjustment handwheel 3 is installed on the frame body 1 through the fixed shaft 31, the outer end of the fixed shaft 31 is a threaded shaft, and the inner end is an optical axis, which is fixedly installed on the frame body 1; the tension adjustment hand wheel 3 Installed on one end of the threaded shaft through threads; the optical shaft is fitted with a taper shaft 33, and the optical shaft and the taper shaft 33 are connected by a guide key; the taper shaft 33 is installed with a driving gear 32, between the taper shaft 33 and the tension adjustment handwheel 3 Springs 34 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com