Antibacterial polyvinyl alcohol water-soluble film and preparation method thereof

A technology of polyvinyl alcohol and polyvinyl alcohol resin, which is applied in the field of daily chemical industry and new materials, can solve problems such as microbial pollution, achieve high antibacterial activity, reduce costs, and inhibit the growth of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

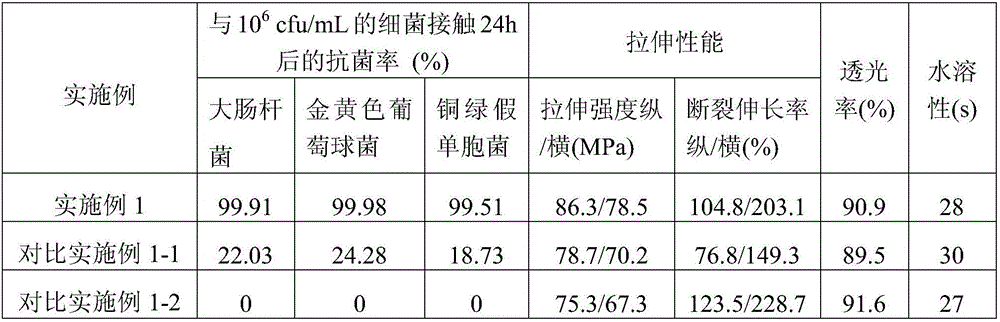

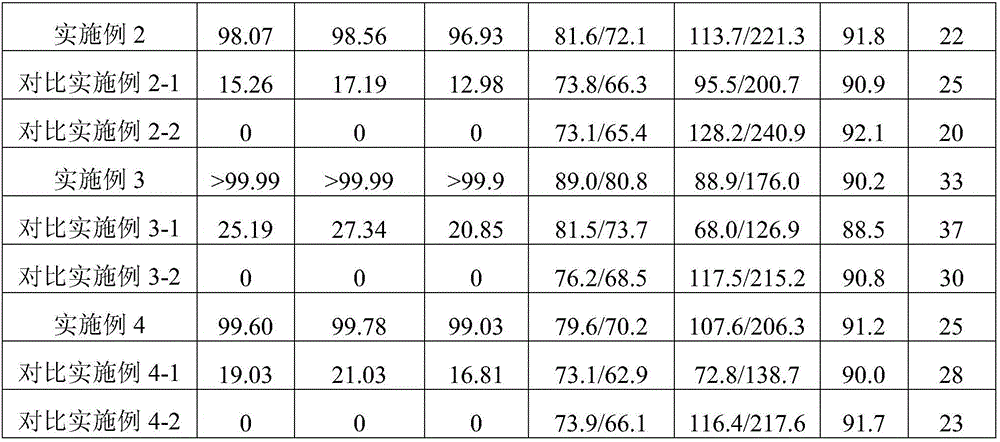

Examples

preparation example Construction

[0035] Preparation of nano-copper-loaded montmorillonite: 1kg Na-based montmorillonite (ion exchange capacity is 1mmol / g) is prepared into a 5wt% (mass fraction) suspension, and then 0.5mol / L of Cu(NO 3 ) 2 1.2L, stirred and reacted in a water bath at 90°C for 6 hours, then added excess ascorbic acid for reduction, then repeatedly washed with deionized water and suction filtered, finally dried and ultrafinely pulverized to obtain nano-copper-loaded montmorillonite, in which nano-copper The mass fraction is 3.1wt%.

[0036] Preparation of nano-copper and quaternary ammonium cationic montmorillonite: disperse 1kg of nano-copper montmorillonite prepared above in 19L deionized water, then add 0.5mol / L brominated bis(dodecyldimethyl ) Ethylene diammonium 1.2L, and adjust the pH value to 7.0, stirred and reacted at 70°C for 7h, then repeatedly washed with deionized water and suction filtered, finally dried and ultrafinely pulverized to obtain nano-copper and quaternary ammonium cat...

Embodiment 1

[0038]In terms of parts by mass, first 72.0 parts of polyvinyl alcohol resin (1788), 13.0 parts of ethylene glycol, 10.0 parts of glycerol, 1.0 parts of nano copper and quaternary ammonium cationic montmorillonite composite antibacterial agent, 3 octadecyl -(3,5-di-tert-butyl-4-hydroxyphenyl) propionate 0.5 parts, bis(2,4,6-tri-tert-butylphenyl) pentaerythritol diphosphite 0.3 parts, water-soluble starch 1.5 parts parts, 0.9 parts of hydroxymethylcellulose, 0.5 parts of calcium stearate, and 0.3 parts of zinc stearate were uniformly mixed in a high-speed mixer at 65° C. to obtain a mixture.

[0039] Then the obtained mixture is added to an extrusion blown film machine, and the blown film is extruded at a temperature of 160° C. to obtain an antibacterial polyvinyl alcohol water-soluble film with a thickness of 0.05 mm.

Embodiment 2

[0044] In terms of parts by mass, 65.0 parts of polyvinyl alcohol resin (1788), 10.0 parts of glycerol (glycerol), 10.0 parts of dipropylene glycol (diglycerin), 10.0 parts of trimethylolpropane, nanometer-loaded copper and quaternary Ammonium cationic montmorillonite compound antibacterial agent 0.5 part, 4-[(4,6-dioctylthio-1,3,5-triazin-2-yl)amino]-2,6-di-tert-butylphenol 0.3 Parts, 0.2 parts of tris(2,4-di-tert-butylphenyl) phosphite, 1.9 parts of hydroxymethyl cellulose, 1.1 parts of calcium chloride, 0.7 parts of zinc stearate, 0.3 parts of magnesium stearate at high speed Mix uniformly at 50° C. in a mixer to obtain a mixture.

[0045] The resulting mixture is then added to an extrusion blown film machine, and the blown film is extruded at a temperature of 150° C. to obtain an antibacterial polyvinyl alcohol water-soluble film with a thickness of 0.04 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap