Multi-purpose drilling and excavating trolley for single track railway tunnel

A single-track railway and multi-purpose technology, applied in tunnels, drilling equipment and methods, earthwork drilling and mining, etc., can solve problems affecting tunnel construction progress, construction cost waste, and not very large, so as to reduce construction organization costs and improve construction efficiency. The effect of speeding up the schedule, reducing time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

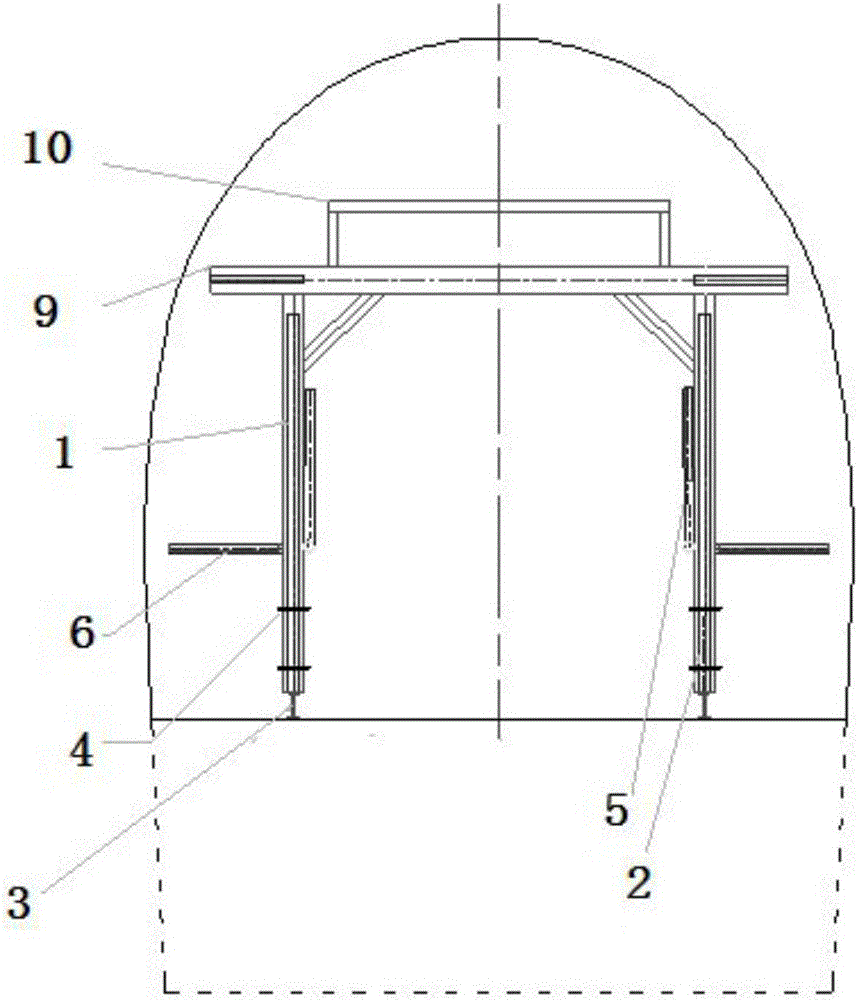

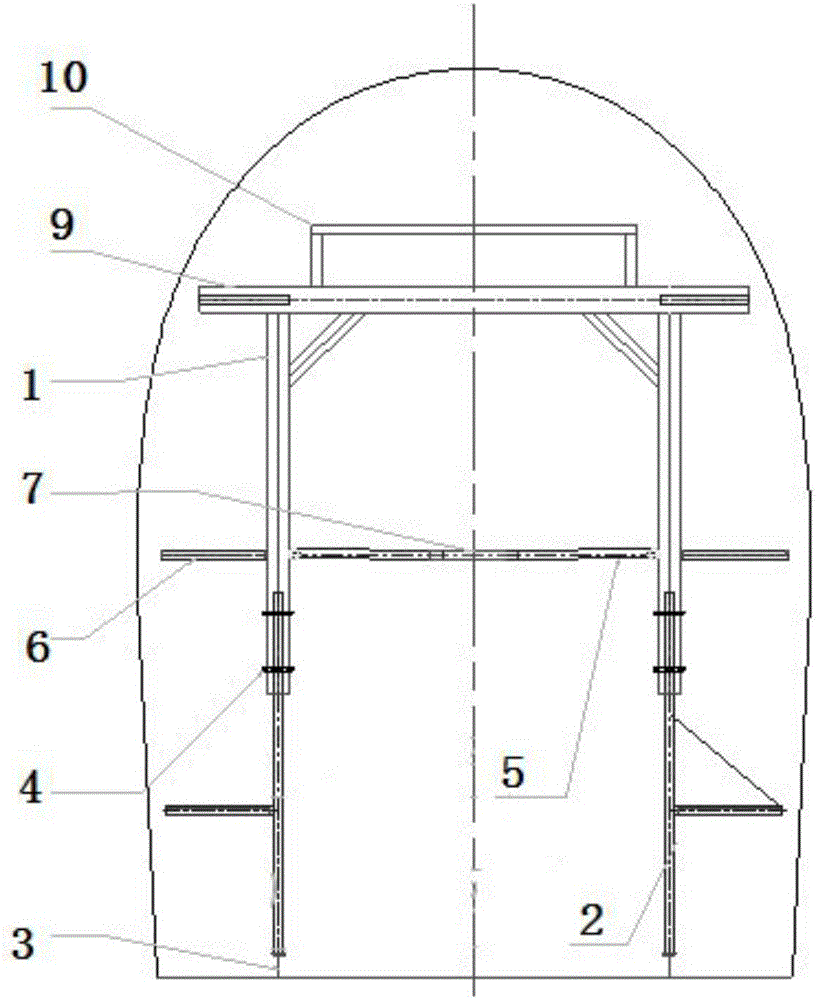

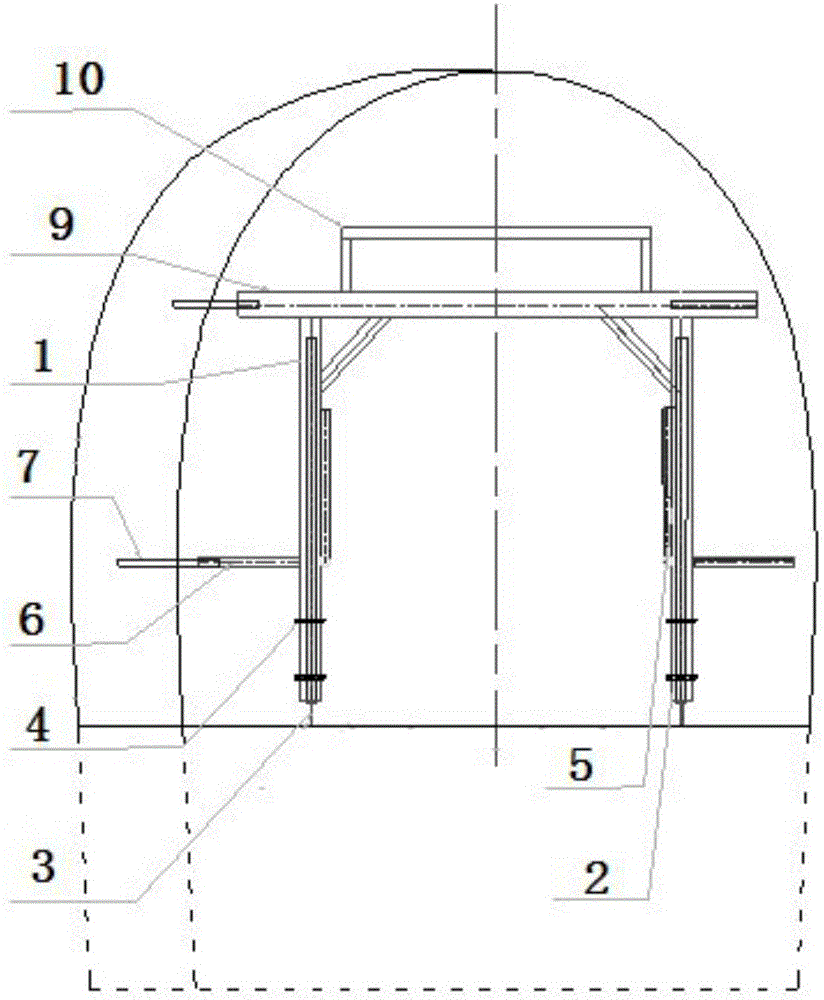

[0034] A multi-purpose drilling and excavation trolley for a single-track railway tunnel, the column (1) of the trolley is set as a hollow structure, the inner groove of the column (1) is provided with telescopic outriggers (2), and the upright column (1) and the inner telescopic outrigger (2) It is locked by the pin shaft (4), and a platform (5) in the layer drilling operation is usually a protective structure, and can form a drilling operation platform after being unfolded; the implementation method is carried out according to the following steps

[0035] S1 According to the step excavation method, the design reference trolley height of the upper step excavation section, and the width of the lower door opening of the trolley must meet the requirements of construction machinery and vehicles.

[0036] The column (1) of the S2 trolley is designed to be hollow, and the telescopic outrigger (2) is installed inside the column. The telescopic outrigger (2) is welded together with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com