Reactive muffler special for inflation of automotive inflation pump

A technology for resistant noise reduction and air pumping, which is applied to pump components, variable displacement pump components, machines/engines, etc., and can solve problems such as high cost, limited application range of this type of muffler, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

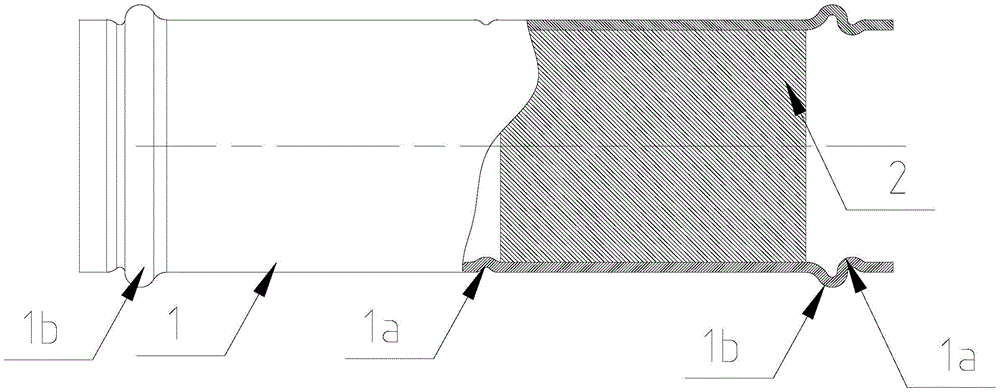

[0024] figure 1 Shown is a specific embodiment of the special resistance muffler for the air intake of the vehicle air pump of the present invention, which includes a metal tube 1, the metal tube 1 is a round tube, and it is filled with a material rolled by a porous mesh material. Formed porous filler 2.

[0025] In this example, the porous mesh material is rolled into many rolls, generally at least one roll.

[0026] Moreover, the porous mesh material is a braided fabric woven from flat yarns (ie, flat filamentous materials), and the mesh number of the braided fabric is preferably 8-12 meshes per square centimeter. During implementation, first weave a cylindrical braid with flat yarn, then radially flatten the braided cylindrical braid to form a double-layer porous braided material, and then roll it into Porous filler 2, the porous filler 2 is inserted into the metal pipe 1 to form a muffler section.

[0027] The flat yarn is preferably selected from a material with strong...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap