Volute of centrifugal fan

A centrifugal fan and volute technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of unsatisfactory design, increase the volume of fan volute, etc., achieve reasonable structure, increase static pressure, and improve fluency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

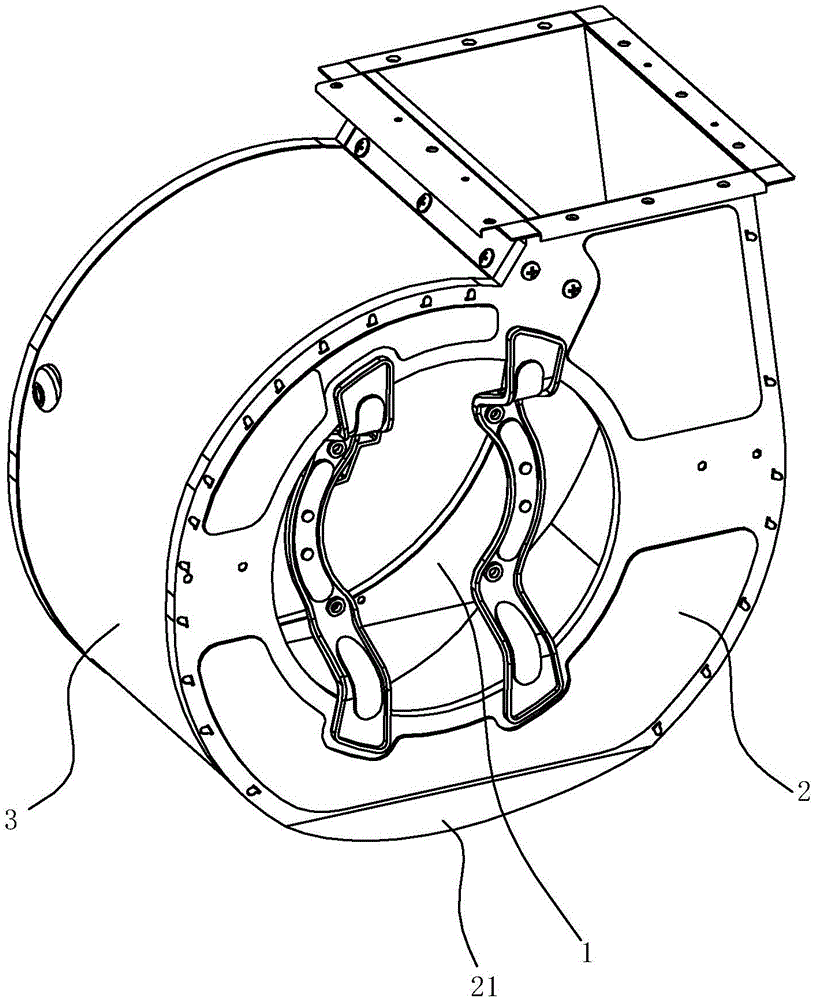

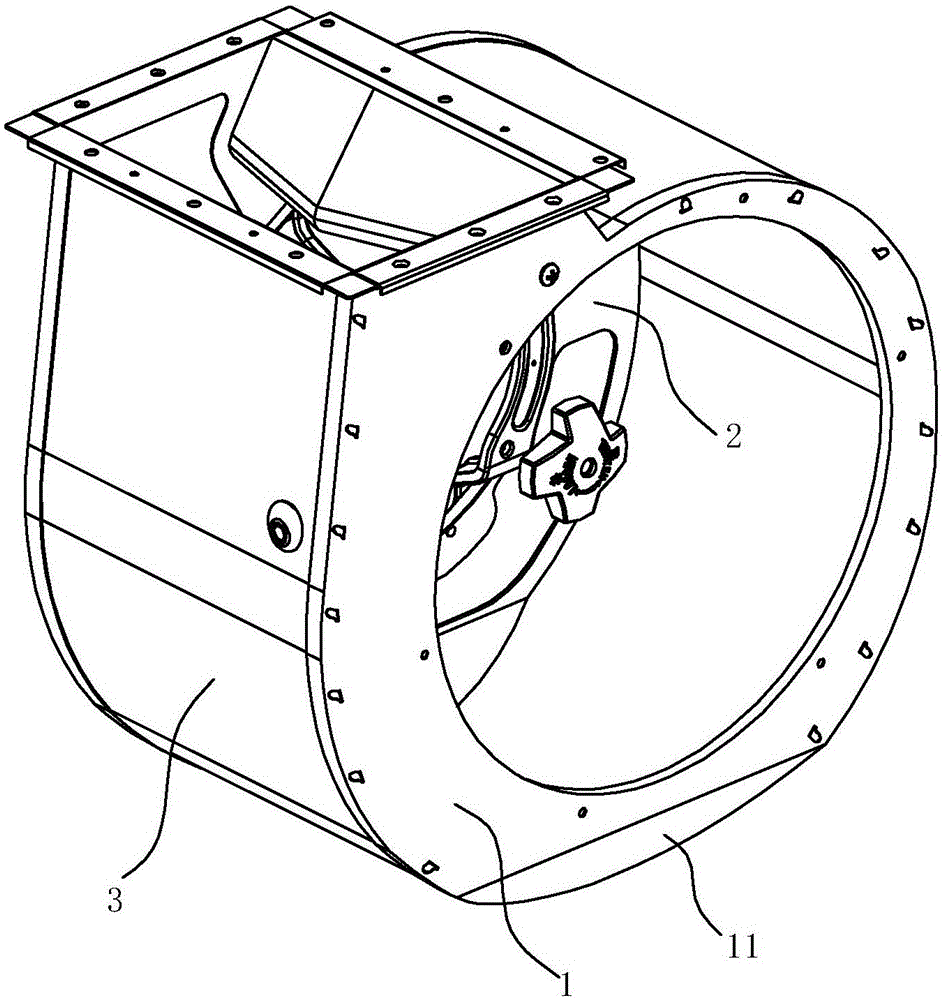

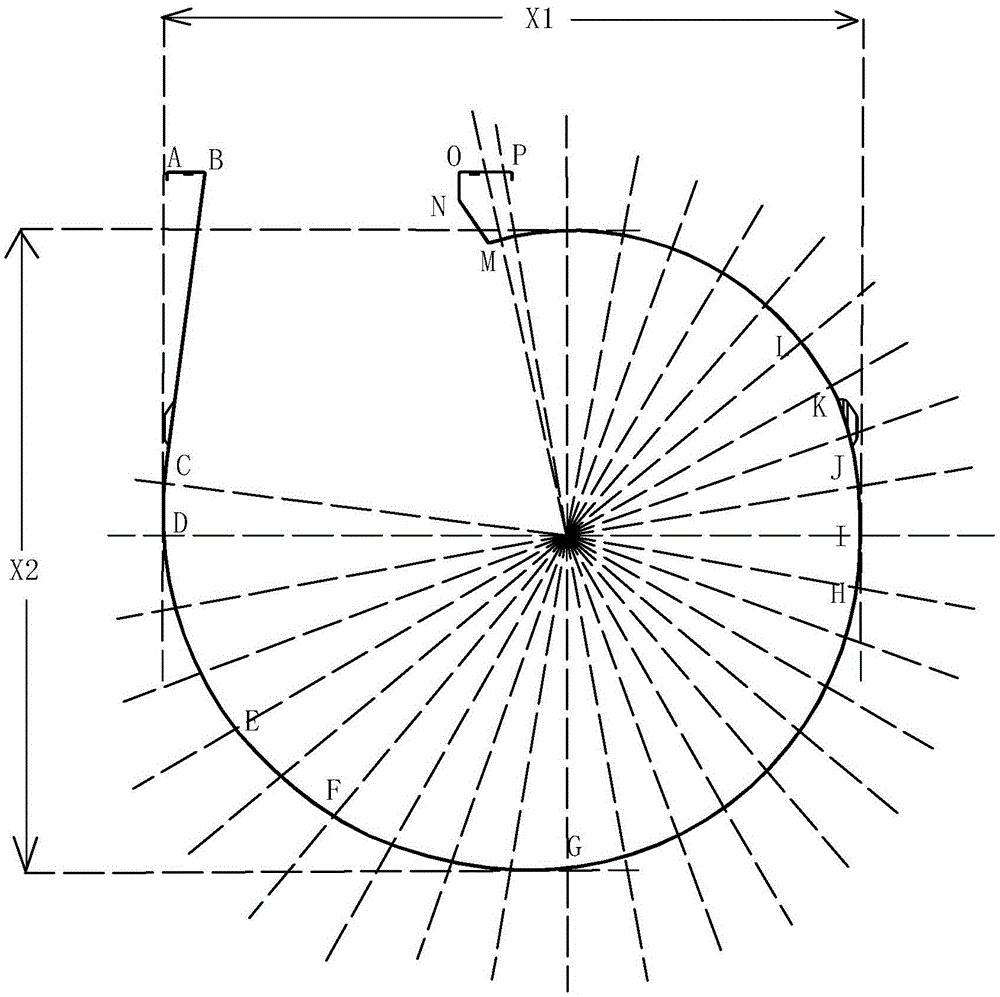

[0019] Such as figure 1 and 2 The volute of the shown centrifugal fan includes a front cover plate 1, a rear cover plate 2 and an annular middle ring wall 3, and the middle ring wall 3 connects the front cover plate 1 and the rear cover plate 1 with a twisted surface with a continuous smooth transition. The cover plate 2 is connected, and the front cover plate 1 and the rear cover plate 2 are respectively provided with a forward air hole and a rear air intake hole, and the projection of the center of the forward air hole on the plane where the rear cover plate 2 is located coincides with the center of the circle of the rear air intake hole , and the edge profile of the front side of the intermediate ring wall is composed of straight line AB, straight line BC, curve CD, curve DE, curve EF, curve FG, curve GH, curve HI, curve IJ, curve JK, curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com