Air inlet silencer for local ventilator

A ventilator and air inlet technology, which is applied to components, machines/engines, mechanical equipment, etc. of pumping devices for elastic fluids, can solve problems such as hidden dangers, affect the normal work and physical and mental health of workers, and reduce Weight, improving the sound-absorbing effect, increasing the sound-absorbing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

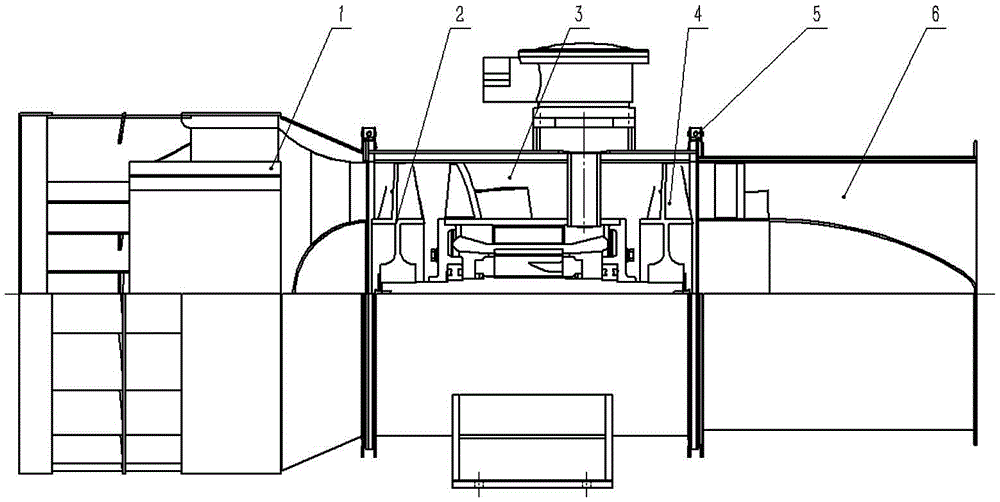

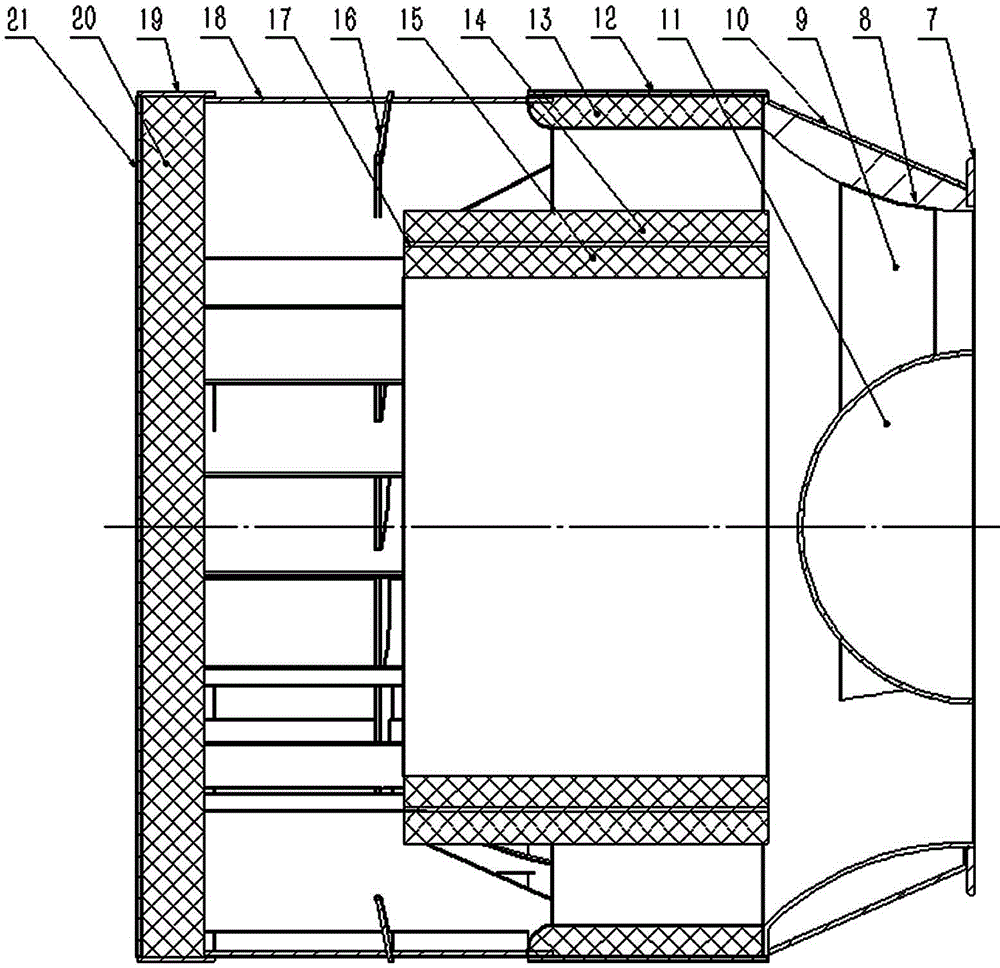

[0027] Embodiment 1, the present invention includes a current collector and a muffler made of plastic, the current collector is a cone-shaped cylindrical structure, the muffler is a straight cylinder, and the larger diameter end of the current collector is fixedly connected with the muffler , the collector includes a collector tube 8, a first support 9, a first conical tube 10, and a plastic suction deflector cap 11; The line position is fixed with a plastic suction diversion cap 11, and a first support 9 is provided between the collector tube 8 and the blister diversion cap 11; the first conical tube 10 and the collector tube 8 form a double-layer structure, which effectively increases the collection capacity. The sound insulation effect of the flow section; the muffler includes a first outer cylinder 12, a first inner cylinder 17, a second outer cylinder 19 and a first conical reflector 16, the first outer cylinder 12 is coaxially installed with the first inner cylinder 17, a...

Embodiment 2

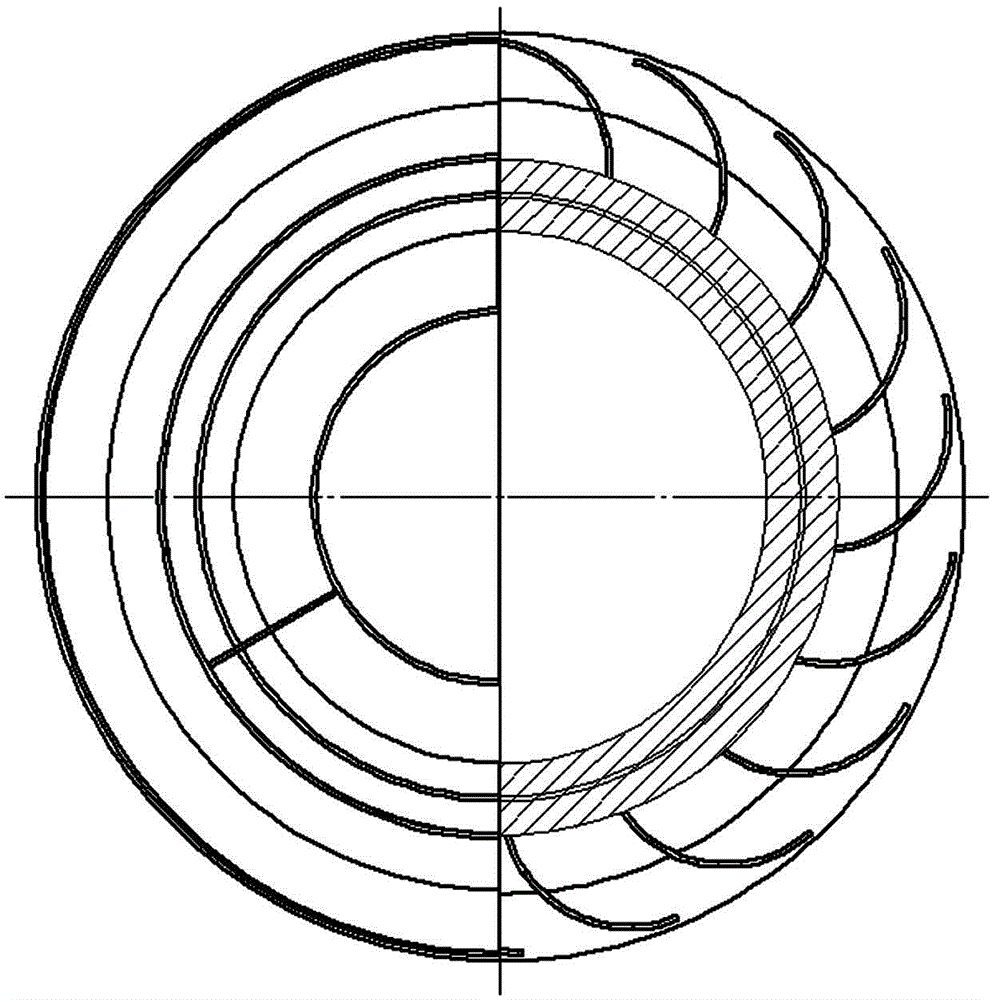

[0029] Embodiment 2, the present invention is provided with two or more first arc-shaped reflectors 18 in the first tapered reflector 16 located between the outer end of the first inner cylinder 17 and the first cover plate 21, The first curved reflector 18 is curved. refer to Figure 1 to Figure 3 , and the rest are the same as the above-mentioned embodiment.

Embodiment 3

[0030] Embodiment 3, the first outer cylinder 12 and the outer cylinder sound-absorbing foam layer 13 of the present invention form an outer ring, the inner-tube outer layer sound-absorbing foam layer 14, the inner cylinder inner layer sound-absorbing foam layer 15 and the first inner cylinder 17 form an inner ring, The multi-ring structure can effectively divide the airflow and increase the noise reduction area; secondly, the side air inlet structure is adopted, and the second outer cylinder 19, the outer sound-absorbing foam layer 20 and the first cover plate 21 can effectively block the linear propagation of radiation noise; The first conical reflector 16 and the n first arc-shaped reflectors 18 evenly distributed along the surroundings prevent radiation noise from spreading outwards by reflecting sound waves. refer to Figure 1 to Figure 3 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com