A Method for Extracting Fault Features of Wind Turbine Bearings Based on Vibration Data

A technology for wind turbines and vibration data, applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve problems such as powerlessness, inability to judge the type of failure, and complex frequency components of vibration signals, and achieve the effect of eliminating noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

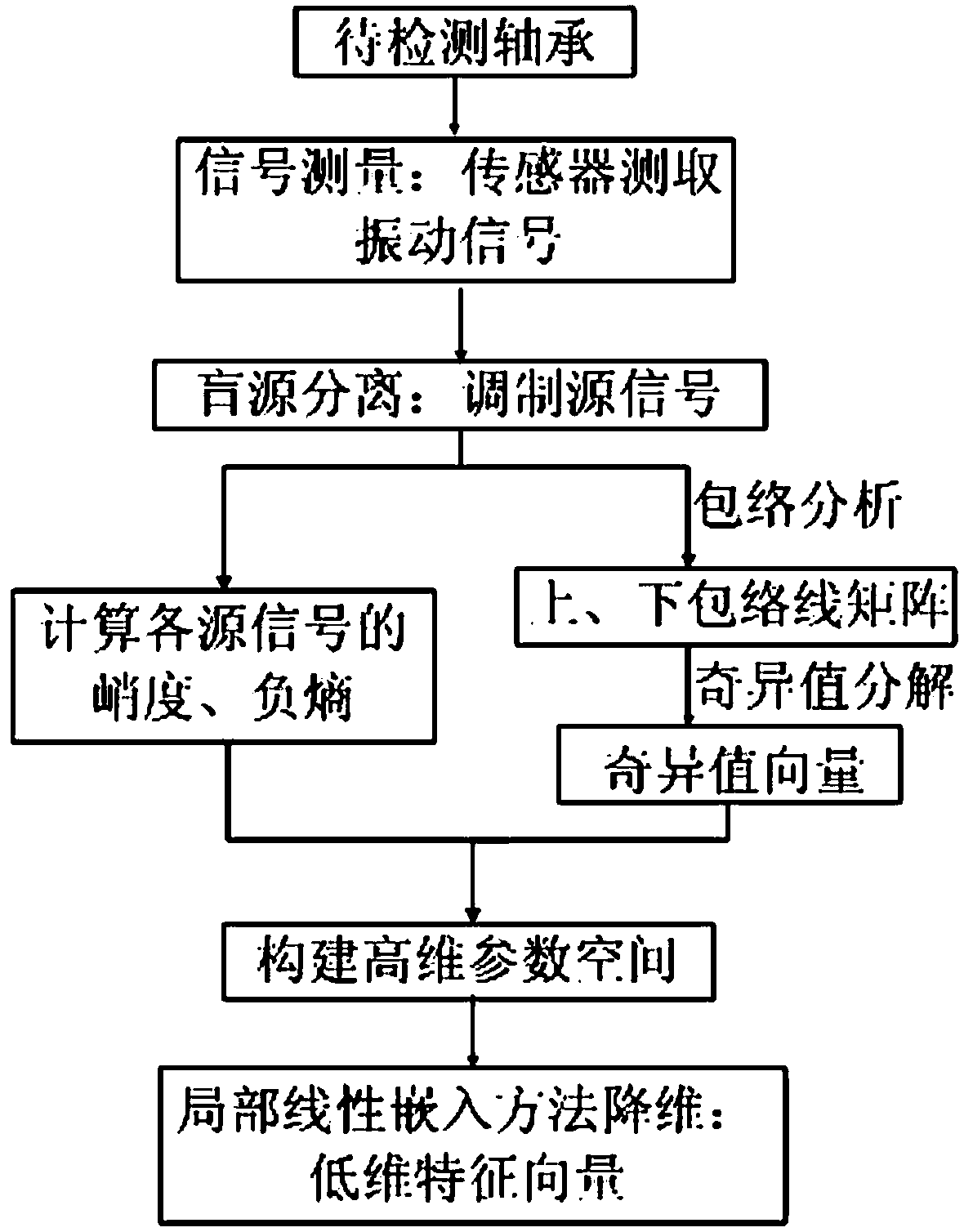

[0068] See attached figure 1 , 2 As shown, the steps of a method for extracting fault features of wind turbine bearings based on vibration data in the present invention are:

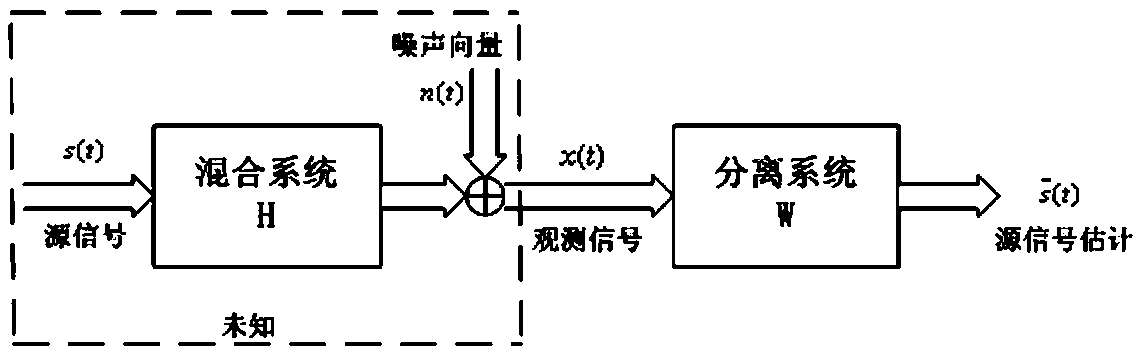

[0069] (1) Use the JADE algorithm to perform blind source separation on the observed signal to obtain the source signal

[0070] Blind source separation refers to the process of separating or estimating the source signal from the observed signal according to the statistical characteristics of the source signal when the source signal and the transmission channel are unknown; the observed signal comes from the output of a set of sensors, each sensor A set of mixtures receiving multiple original signals can be modeled as:

[0071] x(t)=HS(t)+n(t)

[0072] In the formula, x(t)=[x 1 (t),x 2 (t),...,x m (t)] T is the m×1 observation signal, S(t) is the source signal vector; similarly, x(t) is the m×1 mixed signal vector, n(t) is the m×1 noise vector, and m represents the vector The number of rows, H is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com