Fatigue life prediction method and device of wind power generator set

A fatigue life prediction, wind turbine technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as inability to accurately evaluate the fatigue life of wind turbines, and achieve a rigorous, clear, fast and accurate implementation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

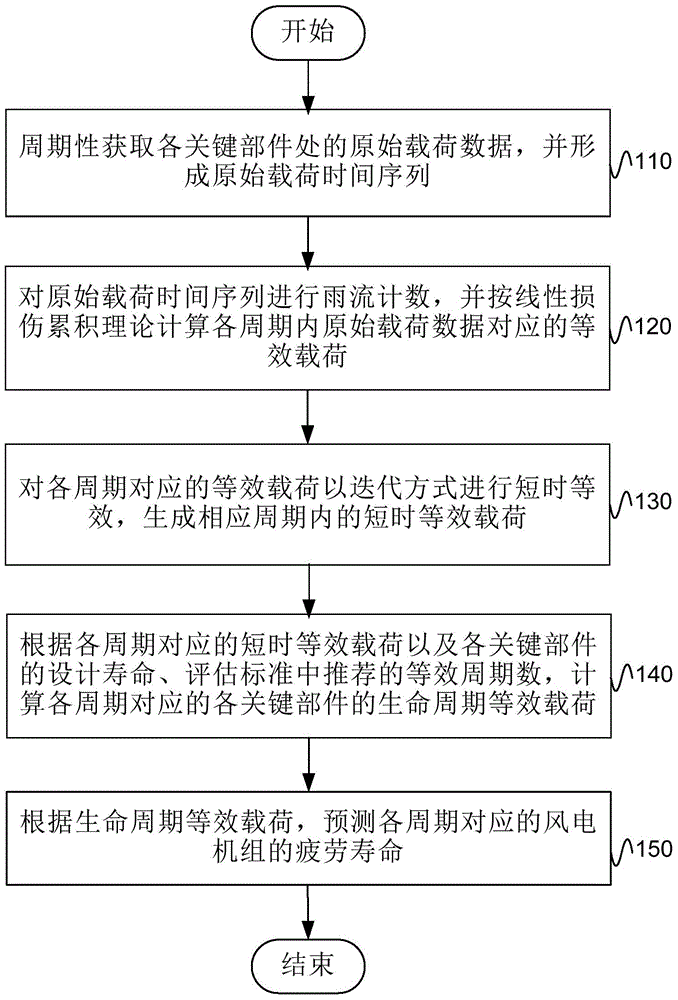

[0017] figure 1 It is a flow chart of an embodiment of the fatigue life prediction method of a wind turbine set provided by the present invention. The execution body of the method may be a controller set in a wind farm, or a controller of a wind turbine set. Such as figure 1 As shown, the method includes the following steps:

[0018] S110. Periodically acquire raw load data at each key component of the wind turbine, and form a time series of raw loads.

[0019] In this embodiment, the original load data at corresponding positions can be detected by setting such as acceleration sensors or strain gauges at key parts, such as the blade root, the main shaft of the wind turbine, the top of the tower, and the bottom of the tower, including: blades Root flapping and shimmy direction bending moment, main shaft torque, main shaft yaw direction bending moment, main shaft pitching direction bending moment, tower top torque, tower top forward and backward thrust and bending moment, towe...

Embodiment 2

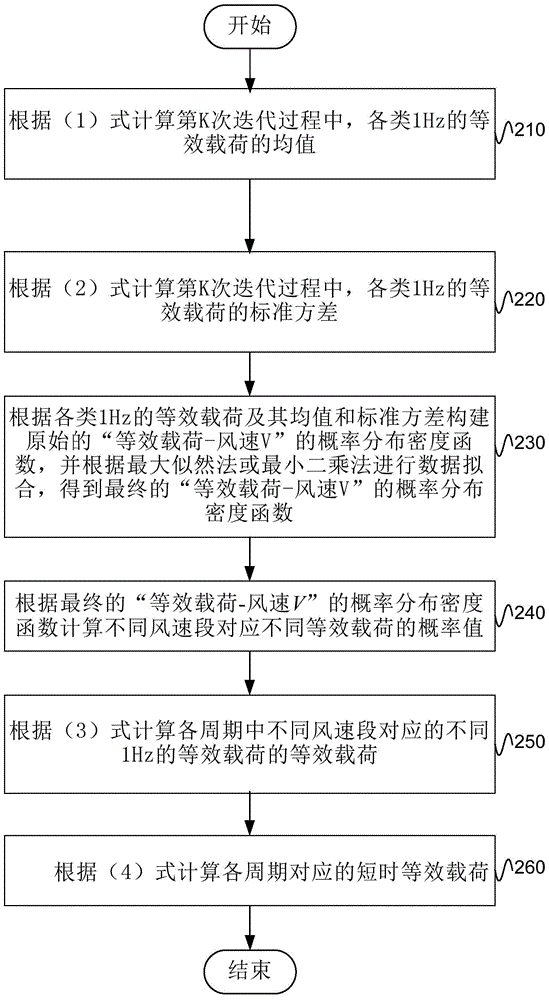

[0040] figure 2 A flowchart of an embodiment of the short-term equivalent load solution method provided by the present invention, the method can be regarded as figure 1 A specific implementation manner of step S130 in the illustrated embodiment. Such as figure 2 As shown, the short-term equivalent load solution method includes the following steps:

[0041] S210, according to:

[0042] μ k = k - 1 k μ k - 1 + 1 k ΔM ( 1 H z ) ... ( 1 )

[0043] Calculate the equivalent load ΔM of each type of 1Hz during the K-th iteration (1Hz) mean μ k .

[0044] Wher...

Embodiment 3

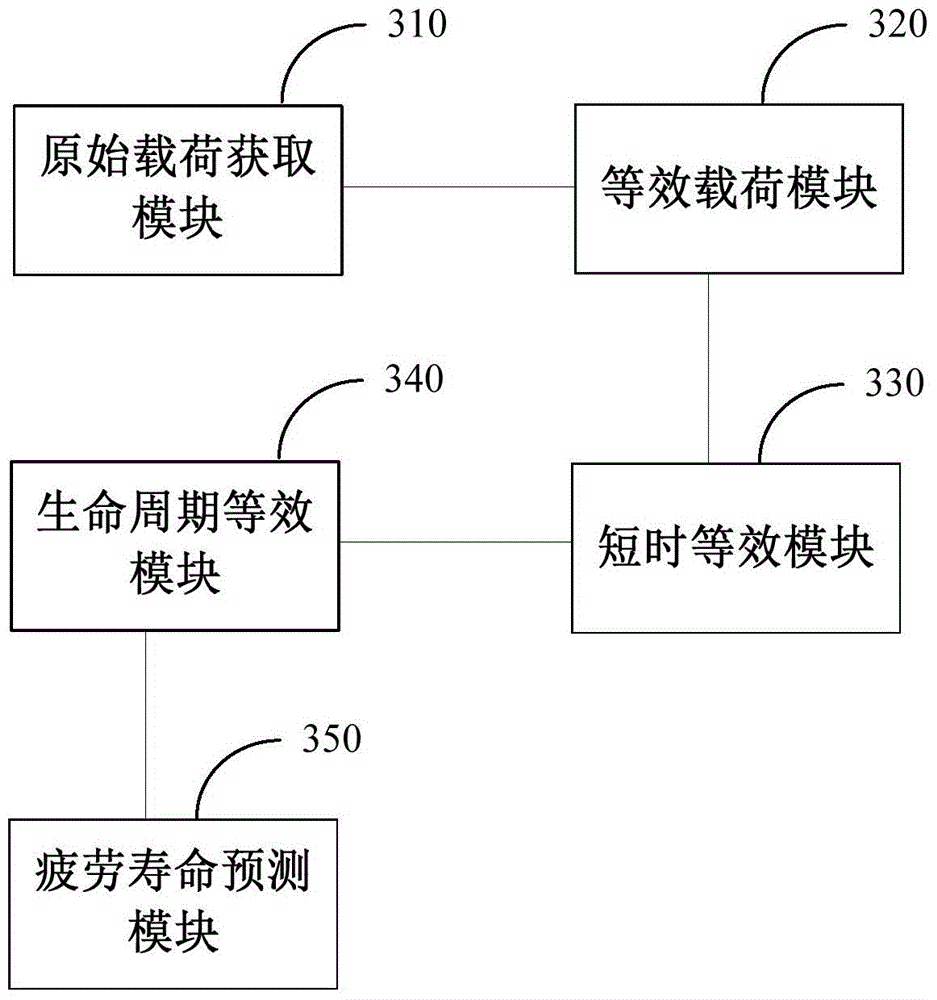

[0066] image 3 The structural block diagram of an embodiment of the fatigue life prediction device for wind turbines provided by the present invention can be used to perform such as figure 1 The method steps shown. Such as image 3 As shown, the device includes: an original load acquisition module 310, an equivalent load module 320, a short-term equivalent module 330, a life cycle equivalent module 340 and a fatigue life prediction module 350, wherein:

[0067] The original load acquisition module 310 is used to periodically acquire the original load data at each key component in the wind turbine, and form the original load time series; the equivalent load module 320 is used to count the rainflow of the original load time series, and press The linear damage accumulation theory calculates the equivalent load corresponding to the original load data in each period; the short-time equivalent module 330 is used to perform short-time equivalent on the equivalent load correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com