Single liquid drop support based external magnetic field driven micro rotating platform, driving method and driving apparatus for micro rotating platform

A technology of rotating platform and external magnetic field, applied in electromechanical devices, electric brakes/clutches, permanent magnet clutches/brakes, etc., can solve the problems of difficult installation and miniaturization, and achieve simple control methods, elimination of friction, and easy control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

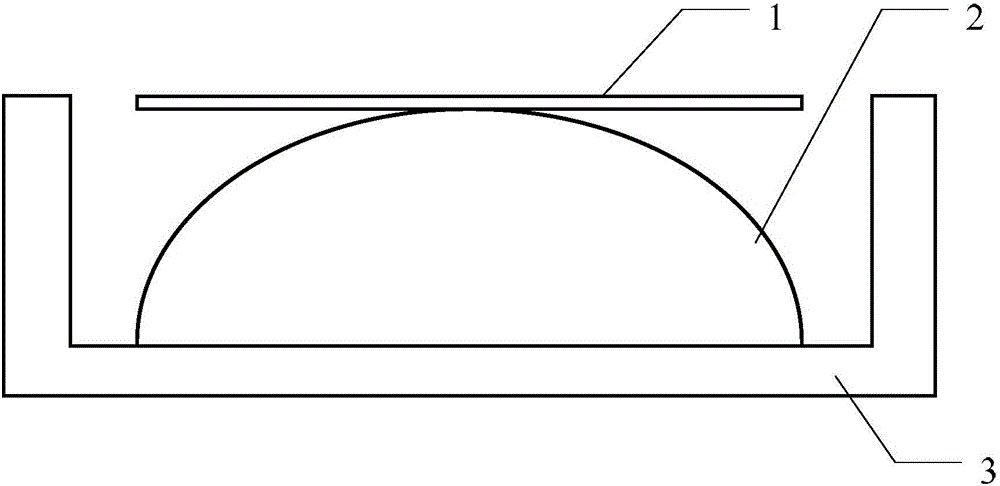

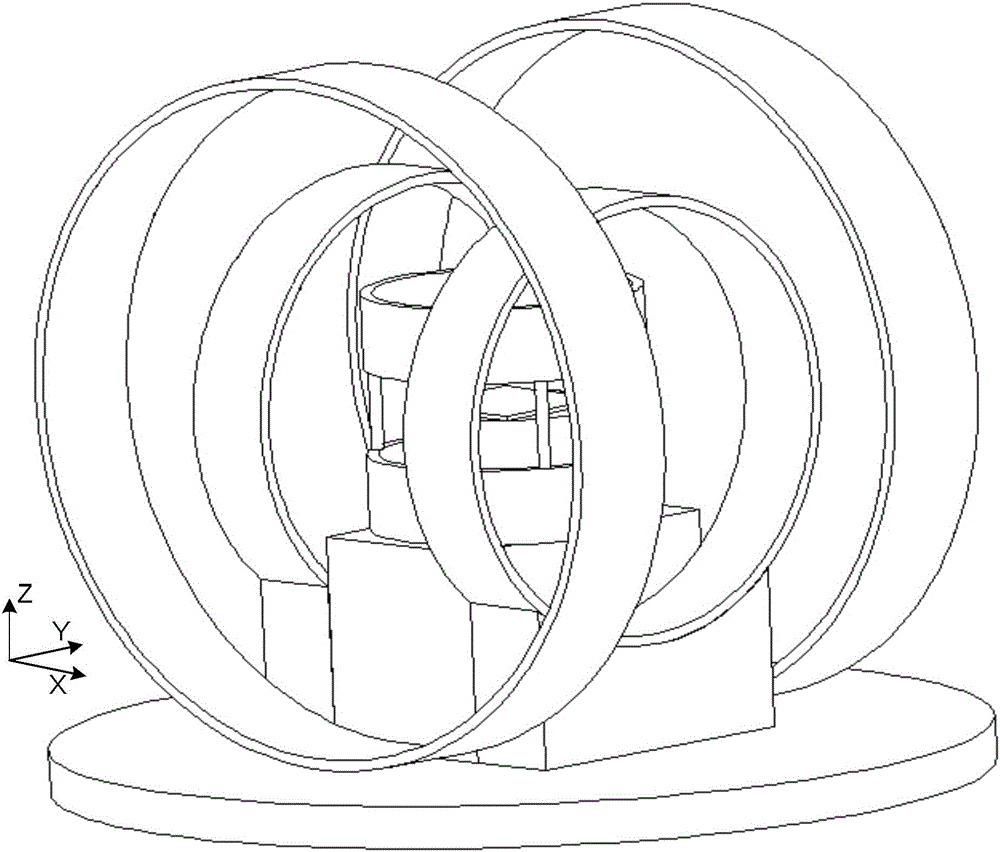

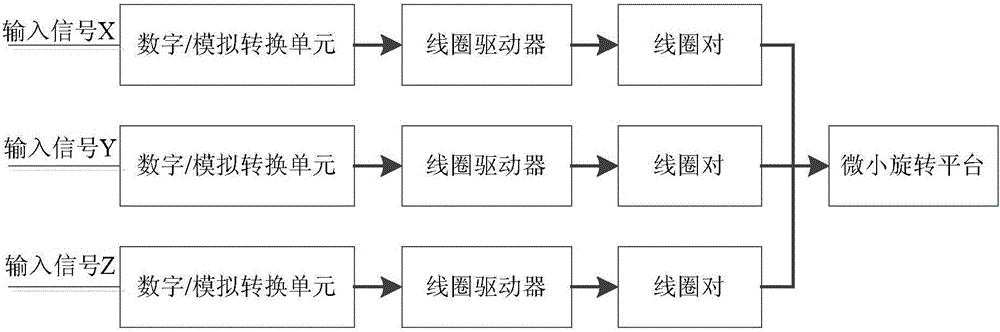

[0023] Specific implementation mode one: refer to figure 1 Describe this embodiment in detail. The micro-rotating platform driven by an external magnetic field supported by a single droplet described in this embodiment includes: a magnetic platform 1, a droplet 2 and a droplet base 3;

[0024] The droplet 2 is located on the droplet substrate 3, and the magnetic platform 1 floats horizontally on the upper surface of the droplet 2.

[0025] An external magnetic field-driven micro-rotating platform based on single droplet support described in this embodiment, wherein the magnetic platform 1 is made of magnetic materials and is magnetic.

[0026] In this embodiment, the capillary force formed between the droplet 2 and the magnetic platform 1 is used to make the magnetic platform 1 adhere horizontally to the upper surface of the droplet 2 . Since the magnetic platform 1 is supported by a single droplet, compared with the existing platform supported by tiny bearing components, the...

specific Embodiment approach 2

[0027] Specific embodiment 2: This embodiment is a further description of the external magnetic field-driven micro-rotating platform based on single droplet support described in specific embodiment 1. In this embodiment, the magnetic platform 1 is a square magnetic sheet, and the material is Spring steel with a thickness of 0.02mm and a length and width of 1mm.

specific Embodiment approach 3

[0028] Specific embodiment 3: This embodiment is a further description of the external magnetic field-driven micro-rotating platform supported by a single droplet described in specific embodiment 1 or 2. In this embodiment, the volume of droplet 2 is 0.3 μL. Droplet 2 is deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com