Secure the Seat Trim Cover to the Foam Insert

A decorative cover, seat technology, applied in vehicle seats, seat covers, transportation and packaging and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

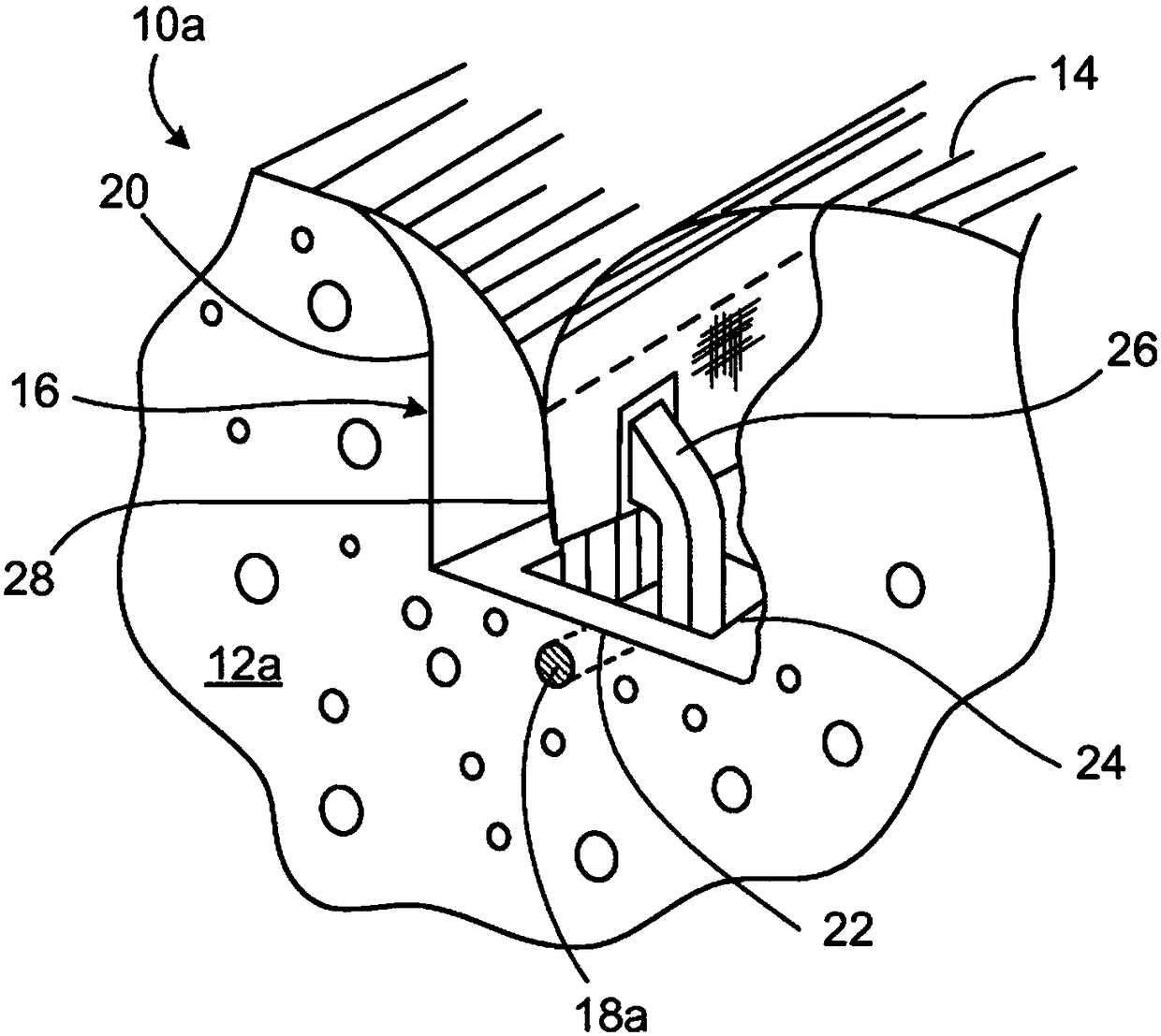

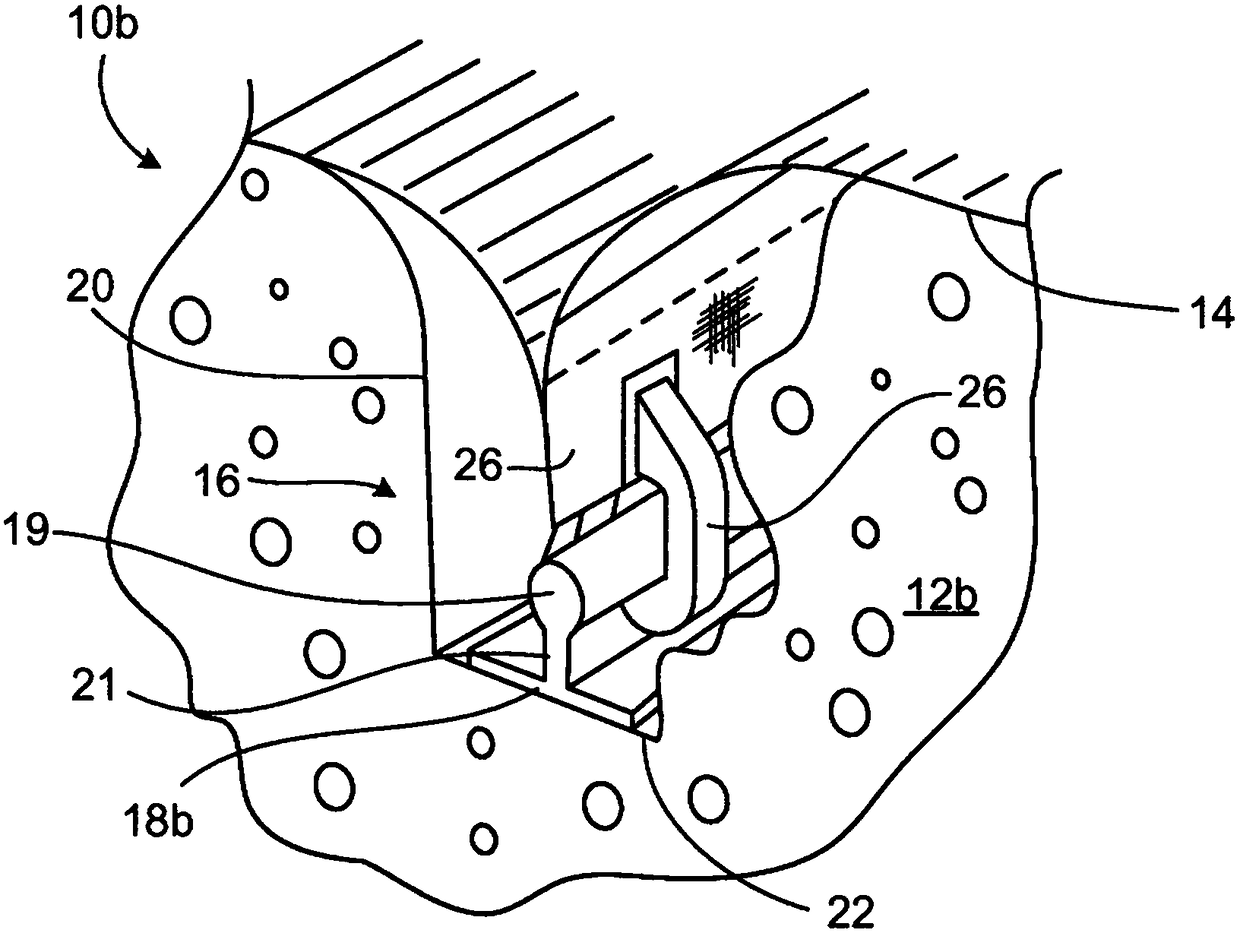

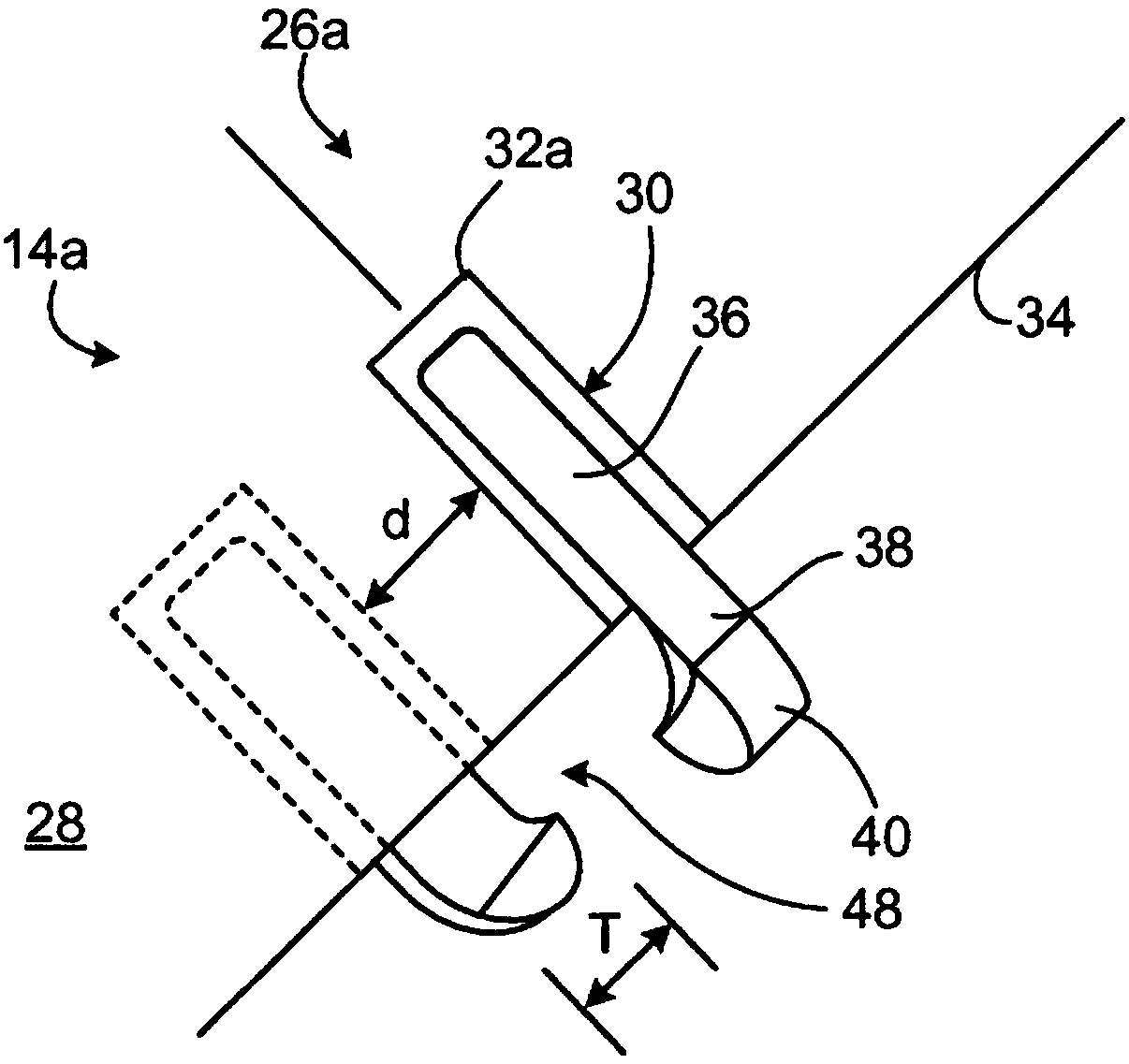

[0101] First refer to Figure 1AAn enclosed foam pad 10a includes a foam block 12a and an outer cover 14 extending over the molded outer surface of the foam block. The surface of the block features an elongated groove 16 where the housing 14 is held in place by a retainer 18a. In this example, the retainer 18a is a wire embedded under the groove 16 within the body of the foam block 12a. The trench 16 is defined by two opposing side walls 20 and a bottom 22 spanning the distance between the two side walls. In this example, the opposing trench sidewalls are parallel to each other and perpendicular to the trench bottom. However, other groove geometries are also conceivable and compatible with the concepts discussed here. The groove is positioned relative to the block profile such that holding the cover tightly against the block at the channel helps to hold the cover tightly against the remainder of the profile of the foam block. In this example, foam padding is designed for us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com