Limiting device

A technology of limit device and flat sheet, which is applied in the direction of positioning device, clamping, support, etc., can solve the problems of height or flatness of parts, failure of other parts to connect normally, and low trimming efficiency, so as to improve accuracy and Reliability, solving stability problems, and scientific and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

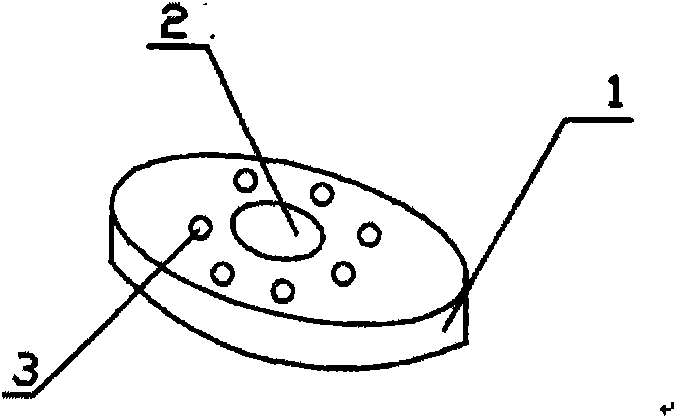

[0012] Such as figure 1 A position-limiting device mainly includes a flat sheet 1, the thickness of which is 10 mm, a transition hole 2 is processed in the middle of the flat sheet 1, and several through holes 3 are processed around the transition hole 2;

[0013] The flat sheet 1 is made of hard rubber.

[0014] A limiting device provided by the present invention adopts the above-mentioned structure. When in use, the parts to be processed are placed on the operating platform, and the parts to be processed pass through the transition hole 2. The connection part and the through hole 3 are fixed by screws. Operation through the limit device can improve the accuracy and reliability of the repair height.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com