3D powder printer and powder dampproof method thereof

A printer and powder technology, applied in the field of 3D powder printing equipment and powder moisture-proof, can solve the problems of loss of economic value, failure to print, material waste, etc., achieve the effect of reducing the agglomeration rate and saving consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

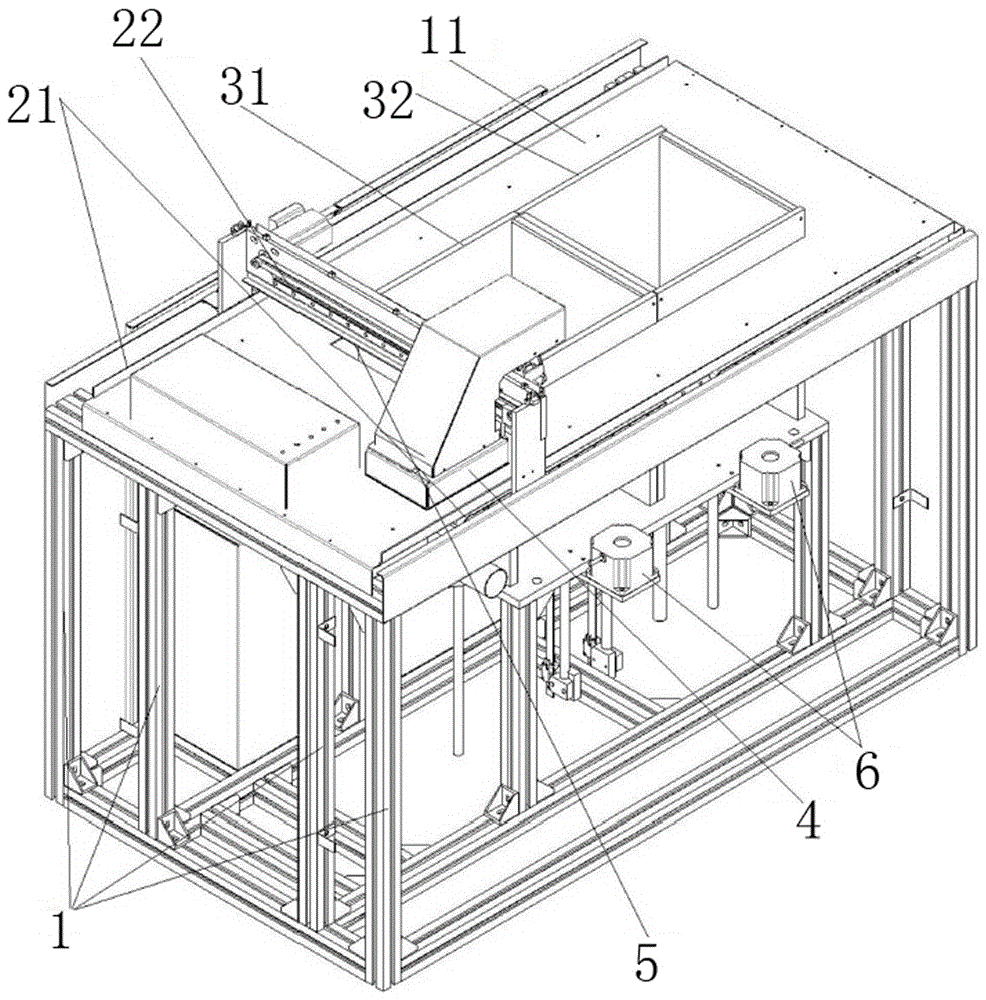

[0015] Such as figure 1 , figure 2 , a kind of 3D powder printing equipment comprises frame 1, and printing platform 11 is arranged on frame 1, and printing platform 11 is provided with the powder chamber of two upper openings, and one is printing chamber 31, and another warehouse chamber 32, The printing platform 11 is provided with a printing head 4 and a powder spreading scraper 5. The printing head 4 is connected to the Y-axis rail 22 through a slider. The rails 21 are respectively fixed on both sides of the printing platform 11 .

[0016] The print head 4 can move in a two-dimensional plane, and its two-dimensional movement is realized by the X-axis track 21 and the Y-axis track 22 . Specifically, the print head 4 slides on the X-axis track 21 to determine the X-axis position, and the X-axis track 21 can slide on the Y-axis track 22 to determine the Y-axis position.

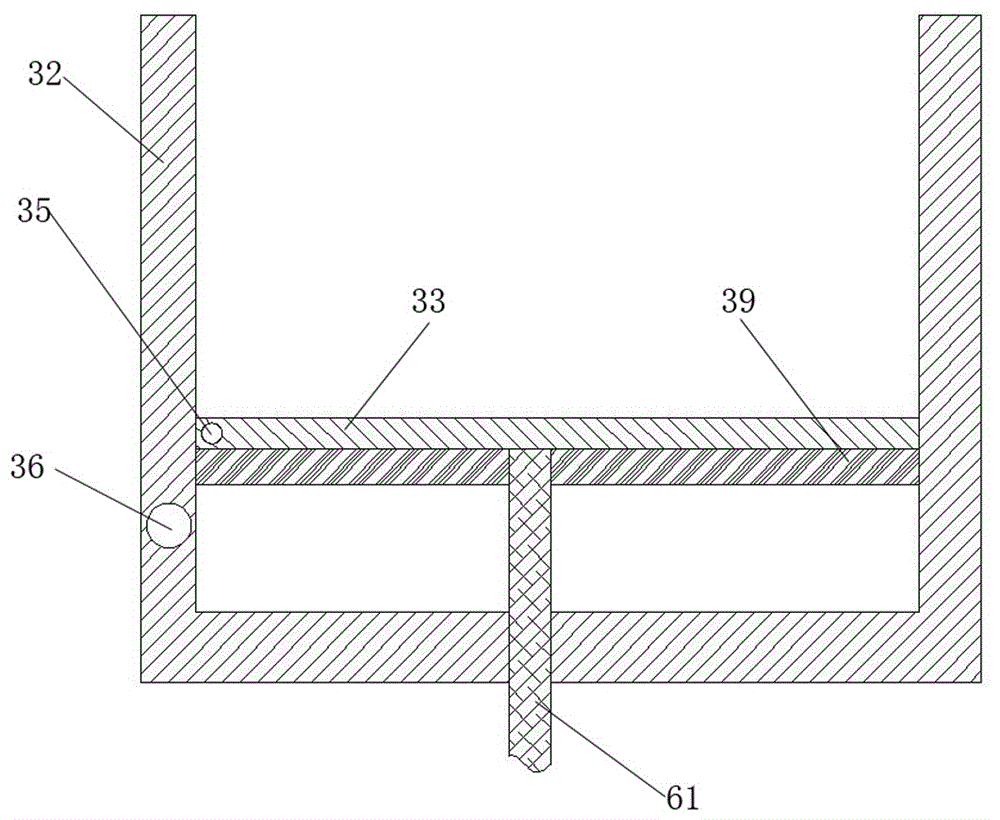

[0017] The bottom plate 33 of the printing room 31 and the warehouse room 32 can reciprocate up and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com