Self-locking mechanism for fast disassembly and assembly of propeller

A technology of propeller and propeller shaft, applied in propellers, aircraft parts, transportation and packaging, etc., can solve problems such as propeller separation, and achieve the effect of convenient propeller, novel and reasonable design, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

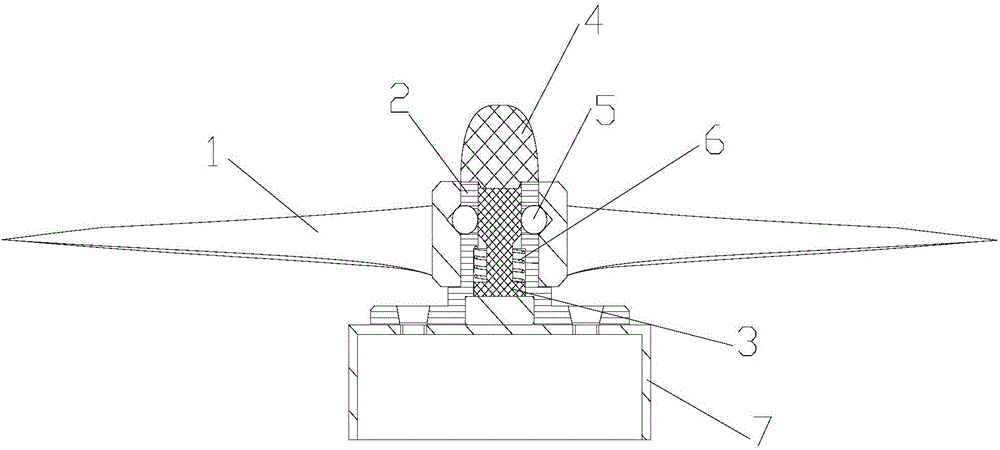

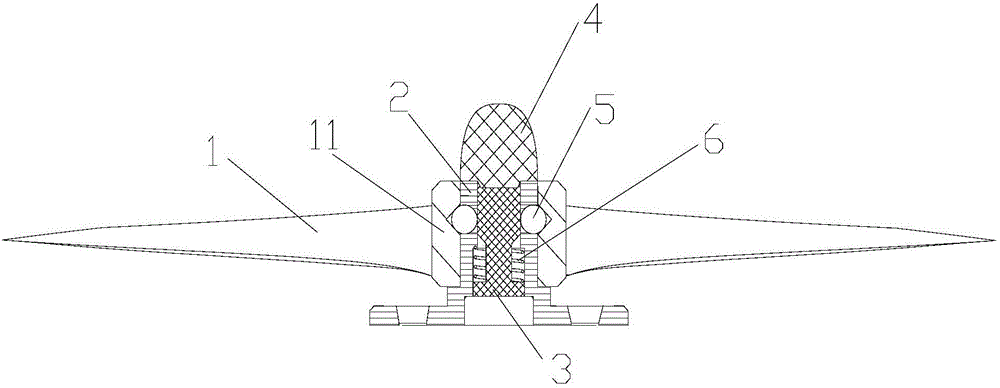

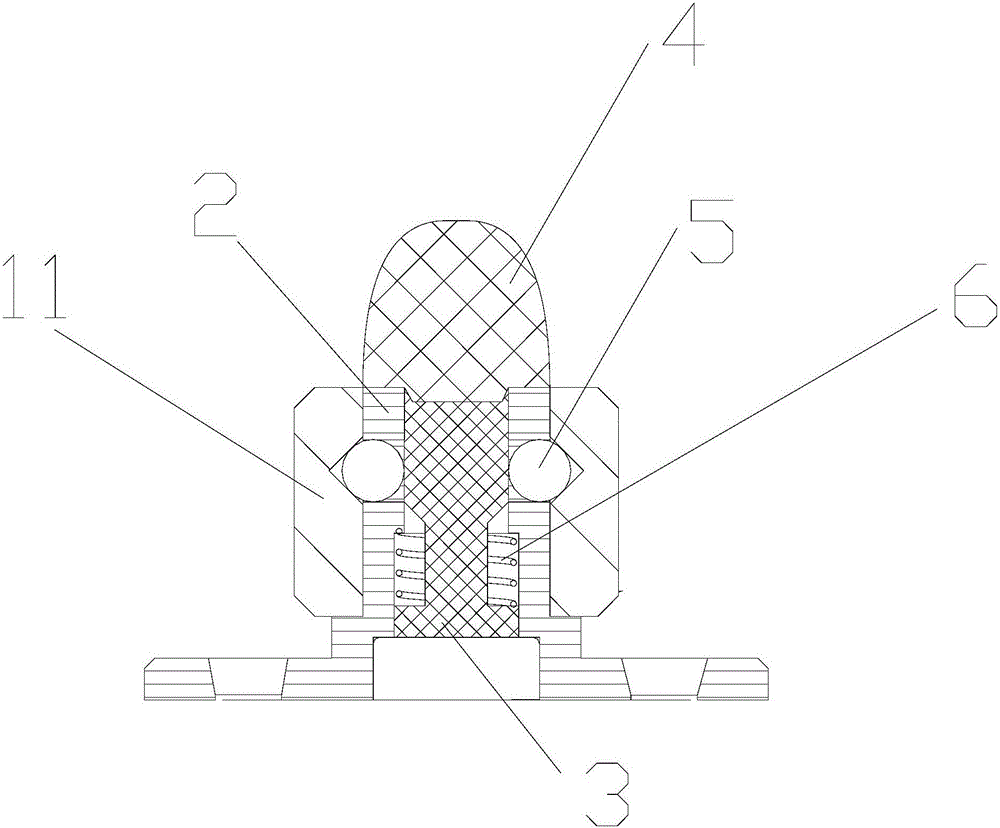

[0069] Embodiment 2, Embodiment 2 of the present invention provides a self-locking mechanism for rapid disassembly and assembly of a propeller, which also has a propeller 1, a propeller installation device 2, a self-locking pin shaft 3, a self-locking pin shaft cap 4, an embedded fitting 5 and a reset Structures such as the spring 6; its above-mentioned specific structural relationship, connection method, etc. are all the same as in Embodiment 1; the only difference lies in the connection structure between the self-locking pin shaft cap and the self-locking pin shaft. obviously, Figure 9 , Figure 10 as well as Figure 11 The specific structural relationship of another embodiment of the present invention (i.e. Embodiment 2) is illustrated respectively, which is the connection mode of the self-locking pin shaft cap and the self-locking pin shaft with the first embodiment, which belongs to the same technical conception.

[0070] continue to see Figure 1-Figure 8 , preferabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com