Polyester resin composition and moldings made therefrom

A polyester resin and molded product technology, applied in the parts of lighting devices, lighting and heating equipment, semiconductor devices, etc., can solve the problems of time reflectance decrease, difficulty in obtaining brightness, deterioration of production capacity, etc., and achieve improved anti-yellowing Effects of denaturation, improved light extraction, excellent initial reflectance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0088] Next, some examples for demonstrating the excellent effects of the polyester resin composition according to the present invention will be described in detail.

[0089] Details of components of the polyester resin compositions used in Examples and Comparative Examples are as follows.

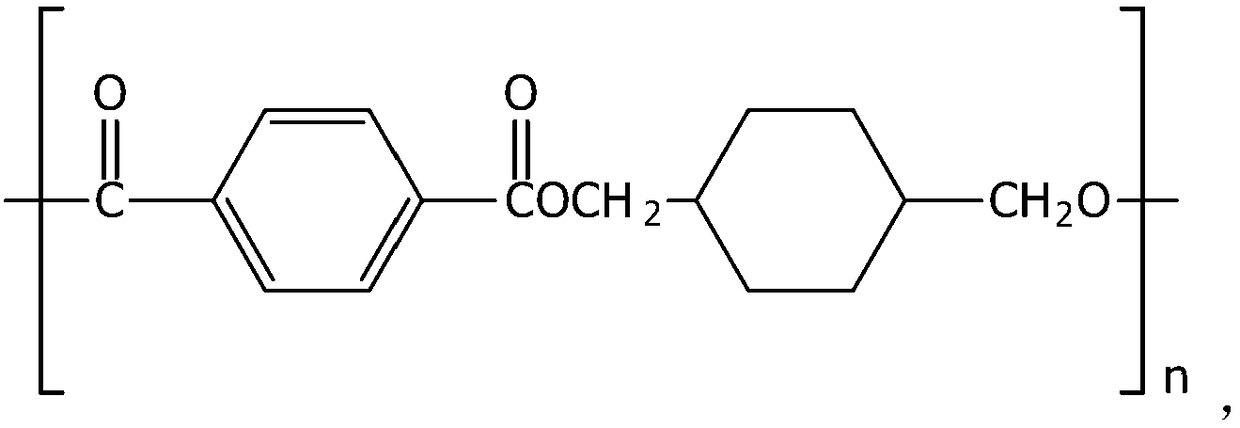

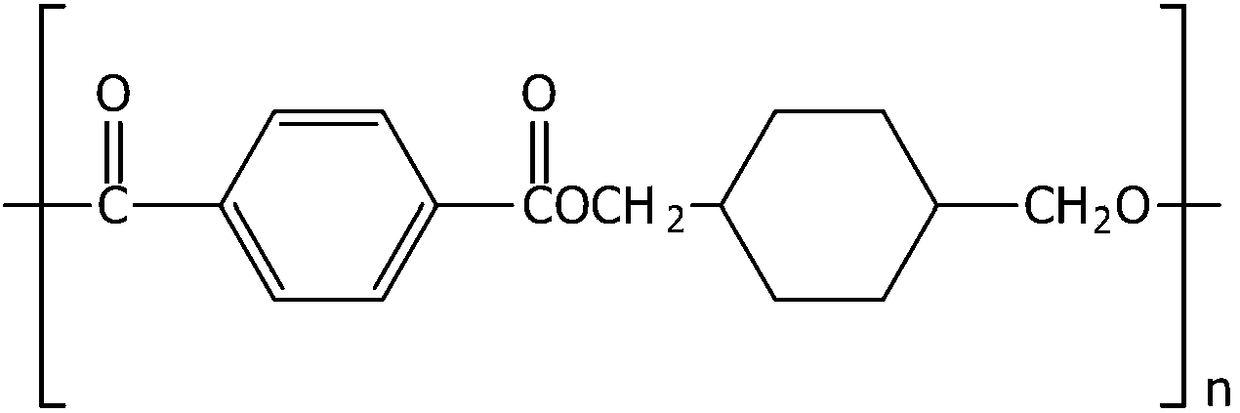

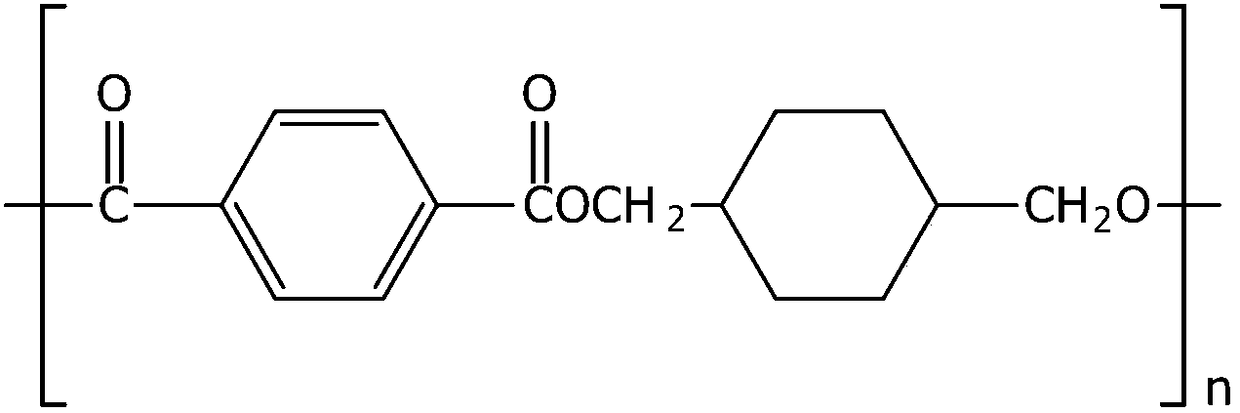

[0090] (a) Polyester resin

[0091] Puratan 0502 (SK Chemical Co., Ltd.) corresponding to poly(hexanedimethyl cyclo-1,4-terephthalate) (PCT) was used.

[0092] (b) white pigment

[0093] CR-470 (Tronox Co., Ltd.) corresponding to titanium dioxide was used.

[0094] (c) Reflectance maintaining agent

[0095] (c-1) A metal inorganic compound (calcium silicate) having a pH of 9.7 was used.

[0096](c-2) A metal inorganic compound (calcium silicate) having a pH of 10.3 was used.

[0097] (c-3) A non-metallic inorganic compound (glass fiber) having a pH of 4.3 was used.

[0098] (c-4) A non-metallic inorganic compound (glass fiber) having a pH of 5.3 was used.

[0099] The components as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com