A ground treatment method

A technology of foundation treatment and steel pipes, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems of difficult control of pile diameter, no economical and effective treatment method, and large difference in bearing capacity, so as to improve the utilization of equipment High efficiency, good effect of immersed tube, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

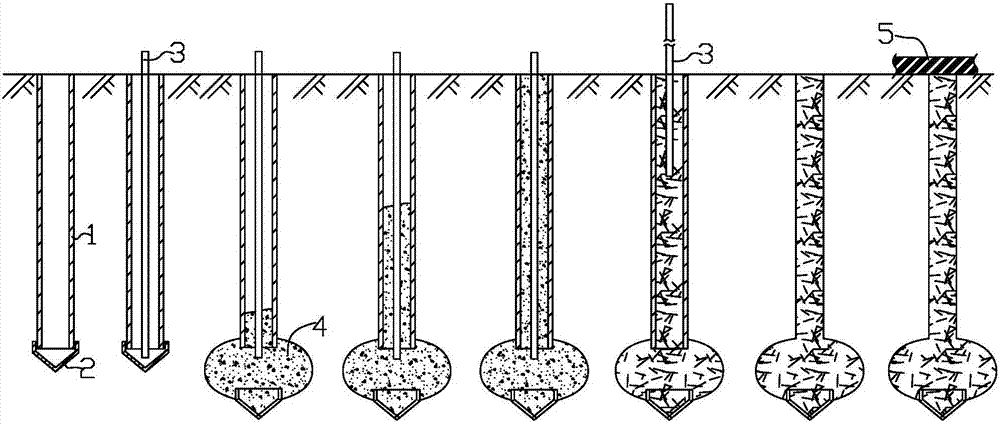

Method used

Image

Examples

Embodiment Construction

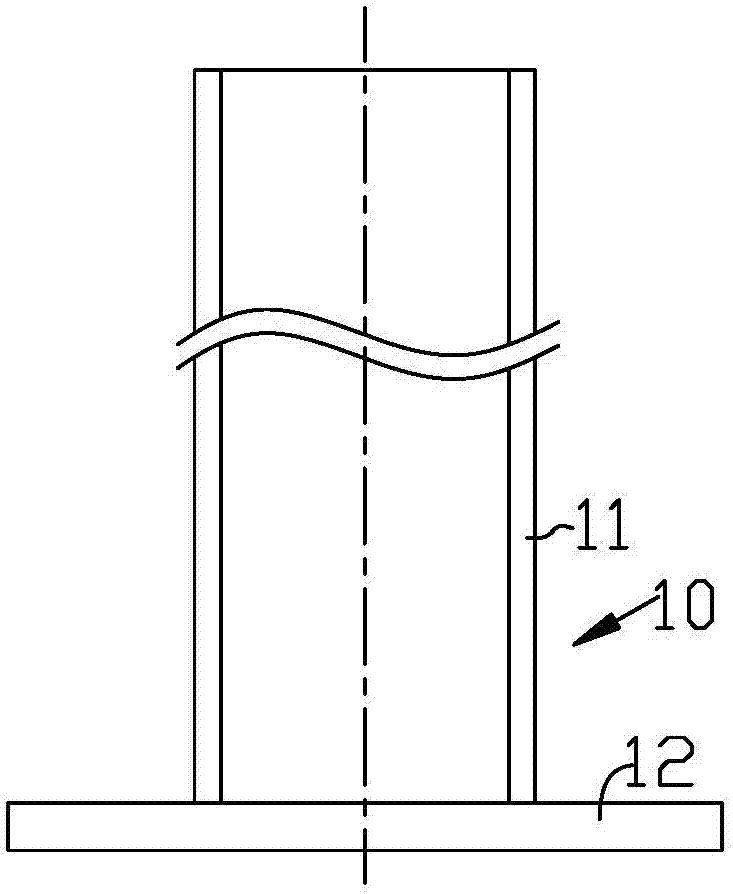

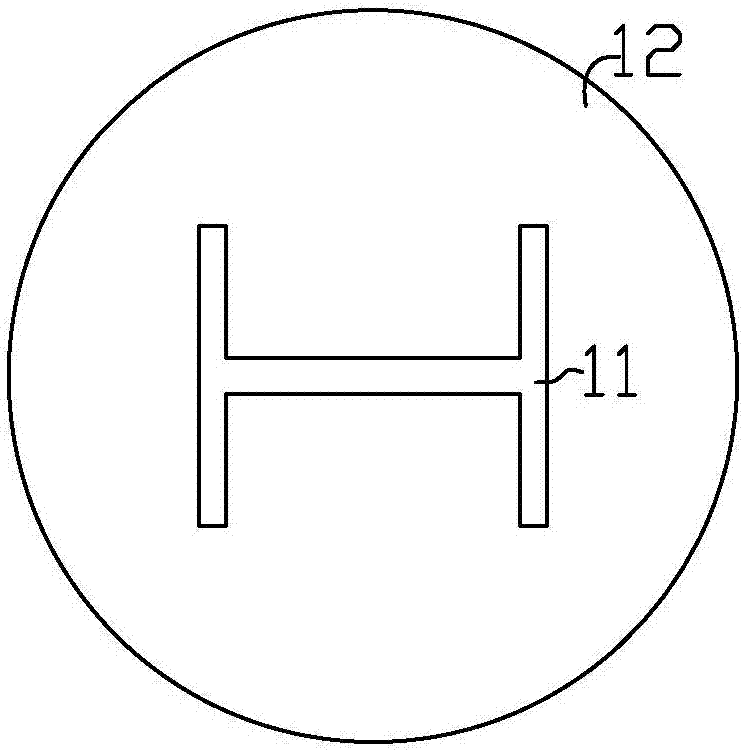

[0044] In this implementation at first make compacting bar 10, refer to figure 2 , image 3 , the compacting bar 10 is the channel steel 11 that the lower end is equipped with the horizontal plate 12, and the horizontal plate 12 is a circular steel plate, and the channel steel 11 and the horizontal plate 12 are welded together, and the diameter of the horizontal plate 12 is smaller than that of the steel pipe used for making the support pile The inner diameter is 180mm smaller to facilitate filling plain soil or construction waste into the steel pipe.

[0045] In this embodiment, the outer diameter of the steel pipe is 426 mm, and the diameter of the expanding head is 800 mm; the vibratory pile sinking and extracting machine uses a Dutch ICE hydraulic vibratory hammer of model 815C, hereinafter referred to as hydraulic vibratory hammer.

[0046] In this embodiment, what is filled into the steel pipe 1 is a mixture of plain soil and construction waste, hereinafter referred to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com