Waterproof sealing construction method for planar joint seam and joint seam waterproof sealing structure for waterproof sealing construction method

A technology of waterproof sealing and construction method, applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of difficult remedial maintenance and emergency maintenance, difficulty, looseness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

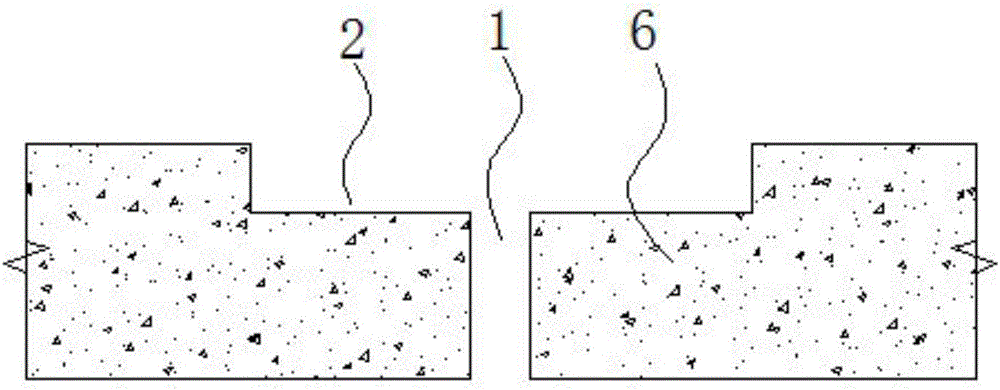

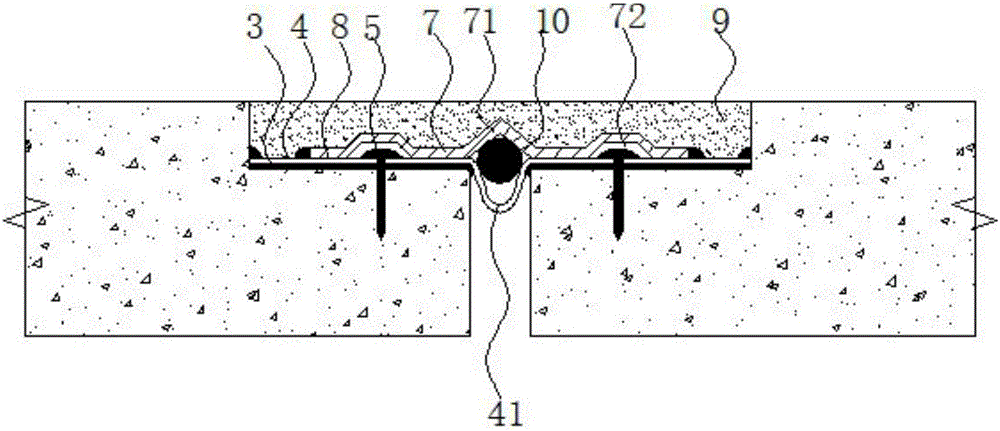

[0025] see figure 1 , 2 , the splicing seam waterproof sealing construction method provided in this embodiment includes the following steps:

[0026] 2) Set a sinking portion 2 on the outer base surface of the side of the planar splicing seam 1, and set the surface of the sinking portion 2 as an uneven rough surface (not shown in the accompanying drawings, but the technology in the art Personnel can clearly), the rough surface is specifically formed by a plurality of evenly distributed cones, and these cones are 0.3-1cm high and 0.3-1cm wide. The cone is formed by embossing the cement slurry leveling layer through a mold before it is completely dry and hard, wherein the cone is a pyramid-shaped quadrangular pyramid, and the distance between two adjacent cones is 1- 3cm. The uneven rough surface formed by these cones is essential, and it plays a vital role in the follow-up and subsequent cooperation with step 2). In the initial construction design, rough surfaces were not u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com