Vertical reciprocating friction-wear testing machine with magnetic shielding function

A friction and wear test, magnetic shielding technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problem that the magnetic shielding effect of the shield is not particularly ideal, cannot monitor the change of the surface topography of the sample, and the reciprocating speed is difficult to control, etc. problem, to achieve the effect of good magnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

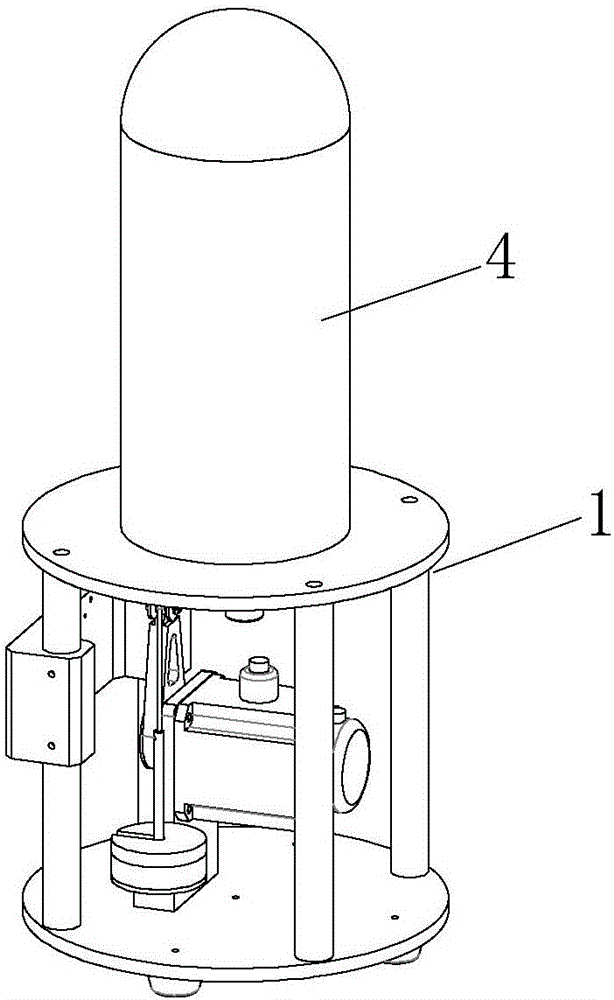

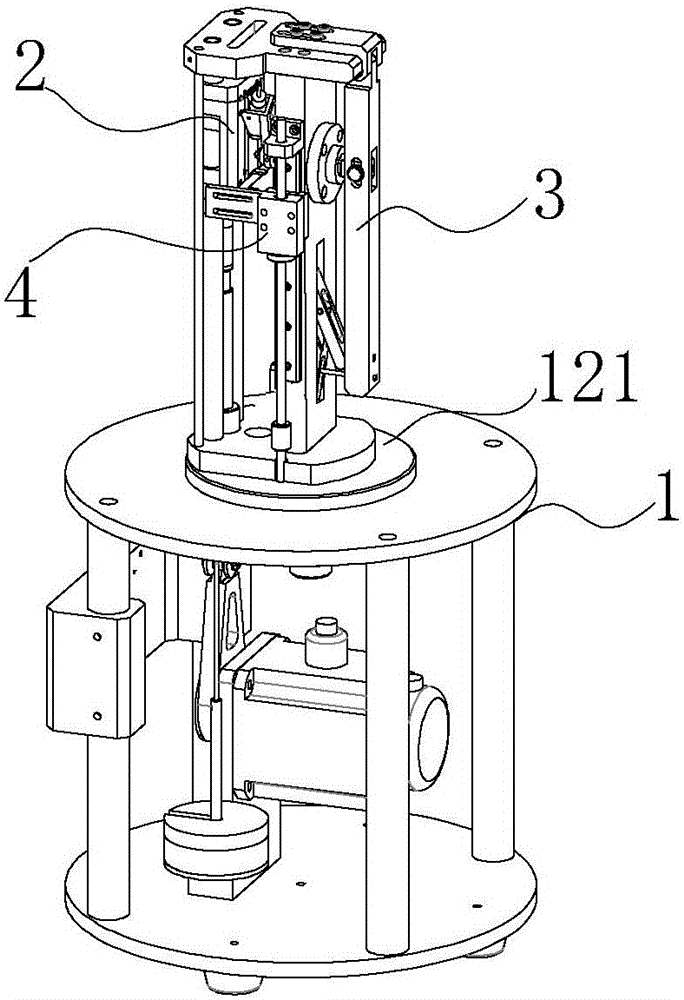

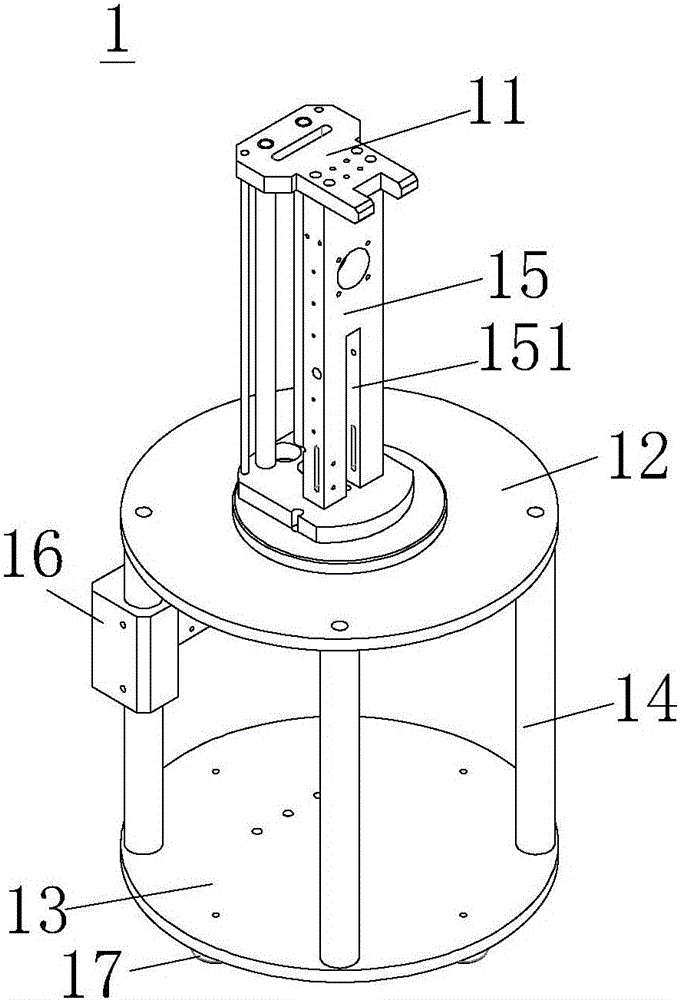

[0065] The present invention proposes a vertical magnetic shielding reciprocating friction and wear testing machine, which includes: a frame, including a top plate, a middle plate and a bottom plate, the middle plate and the bottom plate are connected by a support rod, and the middle plate An intermediate base plate is installed, and a supporting vertical plate is installed between the intermediate base plate and the top plate; the reciprocating mechanism includes a polished rod and a sliding seat for loading block samples, and the polished rod is fixed on the rear end of the top plate and between the middle bottom plate, the sliding seat is movably sleeved on the polished rod, which is driven by a driving device to reciprocate in the vertical direction; the friction loading mechanism is provided with a pressure head assembly, a lever , a support mechanism that can adjust the distance between the lever and the support vertical plate and a displacement loading device that can ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com