A rock permeability test equipment for simulating deep underground rock mass environment

A technology of testing equipment and simulated ground, which is applied in the direction of permeability/surface area analysis, measuring device, suspension and porous material analysis, etc., to achieve the effects of reducing errors, convenient and simple operation, and convenient adjustment and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described.

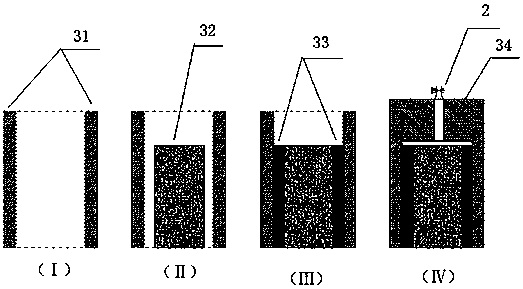

[0026] Such as figure 1 Shown is a schematic diagram of the installation of the rock sample testing platform 3. As shown in the figure, the steps of the installation process are as follows: (I) first place a cylindrical special steel tank 31 with a height of 200 mm and a diameter of 85 mm vertically; (II) place a cylindrical test rock in the center of the steel tank 31 sample 32; (Ⅲ) pour non-shrinkage concrete 33 into the gap between test rock sample 32 and steel tank 31, and keep poured non-shrinkage concrete 33 flush with test rock sample 32; (Ⅳ) after non-shrinkage concrete 33 is hardened, A flange 34 is provided at both ends of the steel tank 3, which are the water inlet flange and the water outlet flange respectively. A water inlet is arranged in the middle of the water inlet flange, and a water outlet is arranged in the middle of the water outlet flange. , and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com