A quick saturation device for soil engineering model test

A geotechnical model and model test technology, used in measuring devices, suspension and porous material analysis, scientific instruments, etc., can solve problems such as soil disturbance, soil seepage damage, difficulty in detecting saturation effects, etc. , the effect of fast saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

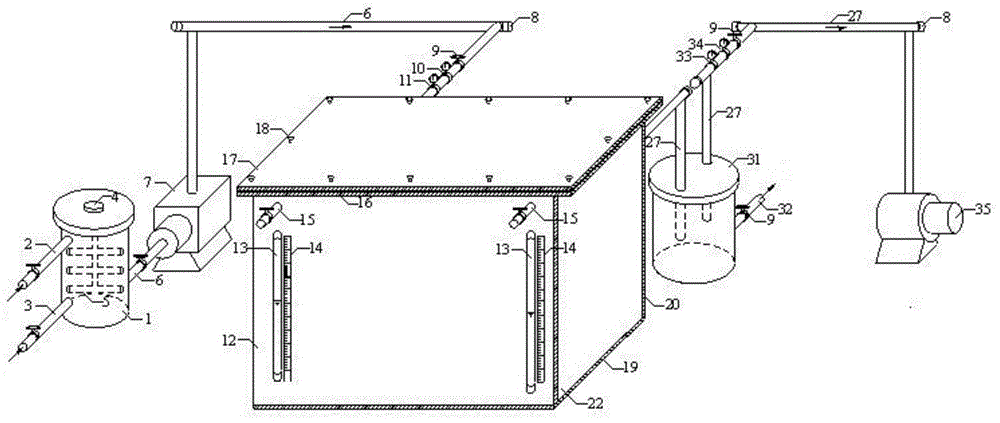

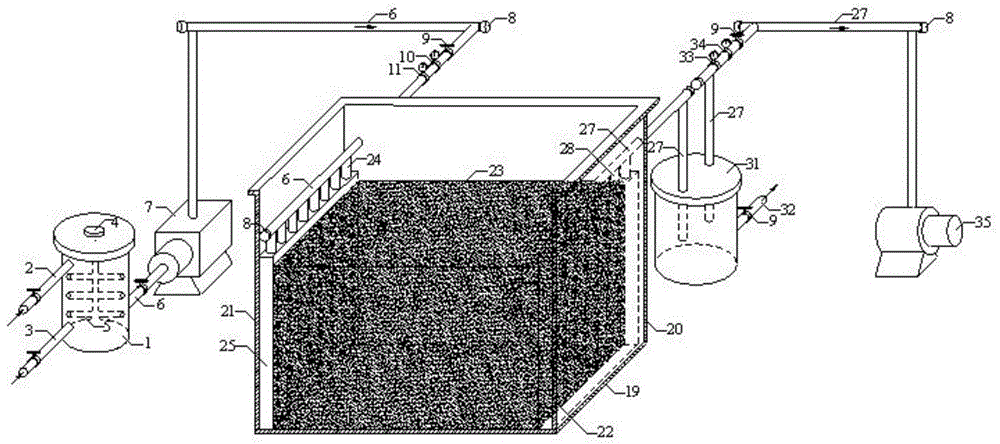

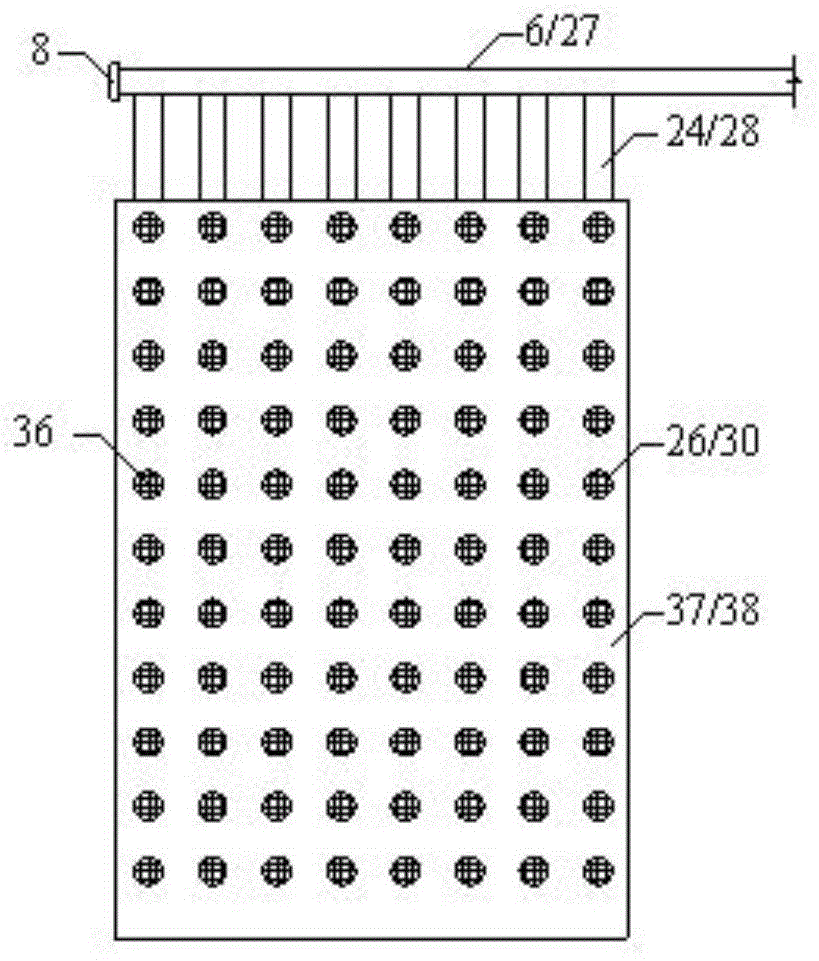

[0038] Such as Figure 1~2As shown, a rapid saturation device for geotechnical model tests, the device includes a saturated liquid mixing tank 1, a saturated liquid inlet pipe 6, a liquid pump 7, an air outlet pipe 27, a sealed gas-liquid separation tank 31, a vacuum pump 35 and a model test box , the saturated liquid mixing barrel 1 is sequentially connected to the liquid pump 7 and the liquid inlet of the model test box through the saturated liquid inlet pipe 6, and the air outlet of the model test box is connected to the sealed gas-liquid separation through the air outlet pipe 27 in turn. Bucket 31 and vacuum pump 35. One side wall of the saturated liquid mixing tank 1 is provided with two openings for connecting the liquid inlet pipe of the saturated liquid component a2 and the saturated liquid component b3, and a The opening is used to connect the saturated liquid inlet pipe 6; a stirring motor 4 is arranged above the saturated liquid mixing tank 1, and the power rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com