Variant design method of meeting engineering constraint conditions

A technology of variant design and constraint conditions, applied in constraint-based CAD, design optimization/simulation, calculation, etc., to improve efficiency, facilitate model parameter modification and batch modification of APDL code, and shorten the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the specific content of the present invention will be further described below in conjunction with the accompanying drawings, but the specific embodiments of the present invention are not limited thereto.

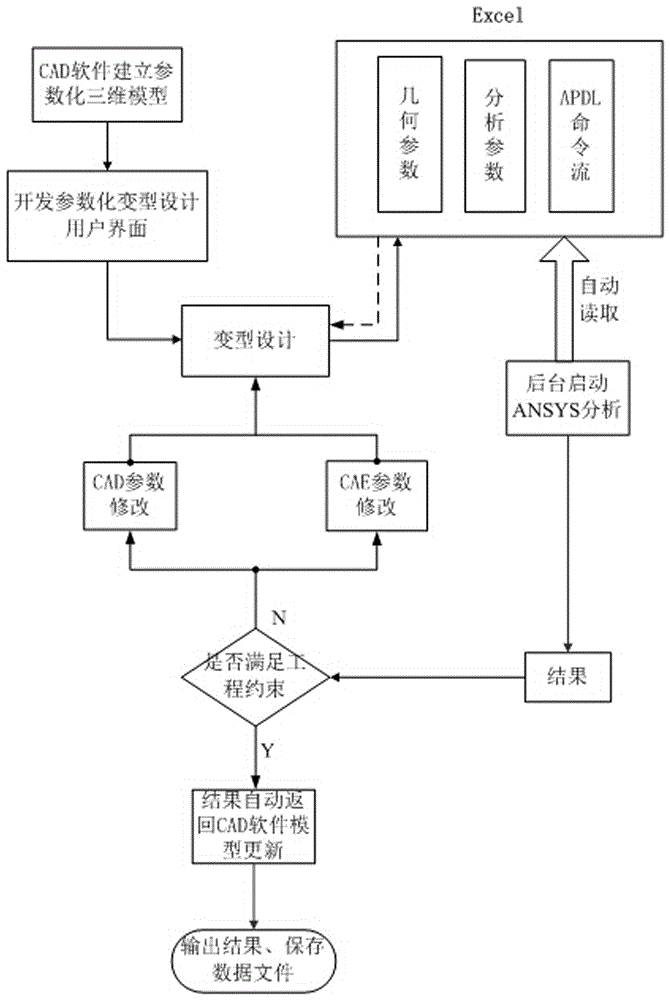

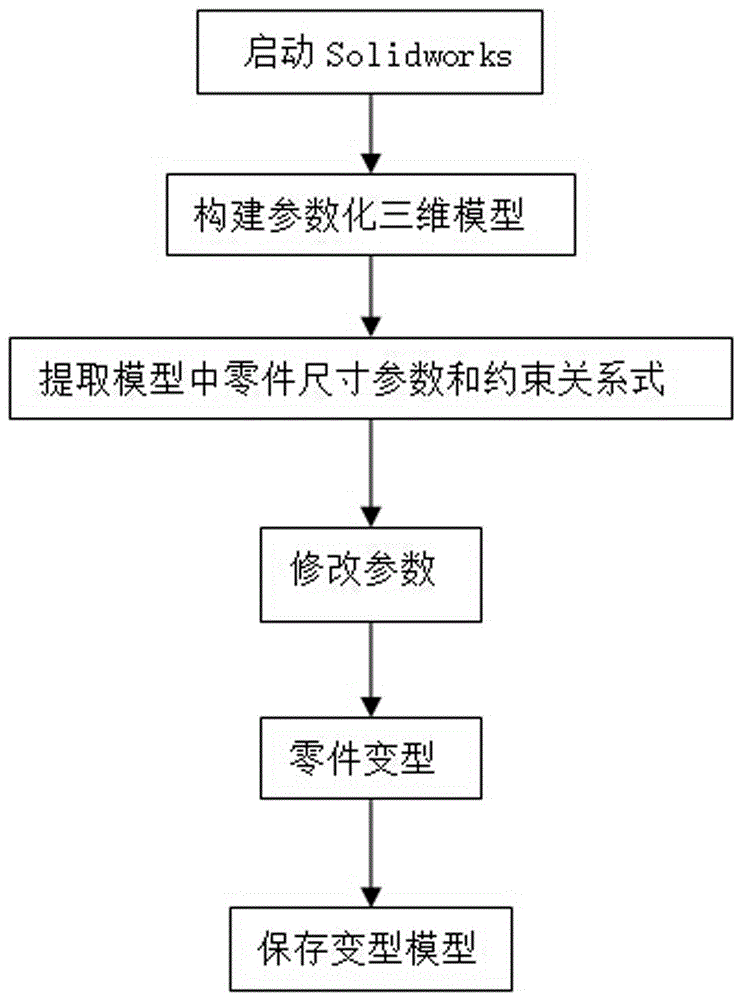

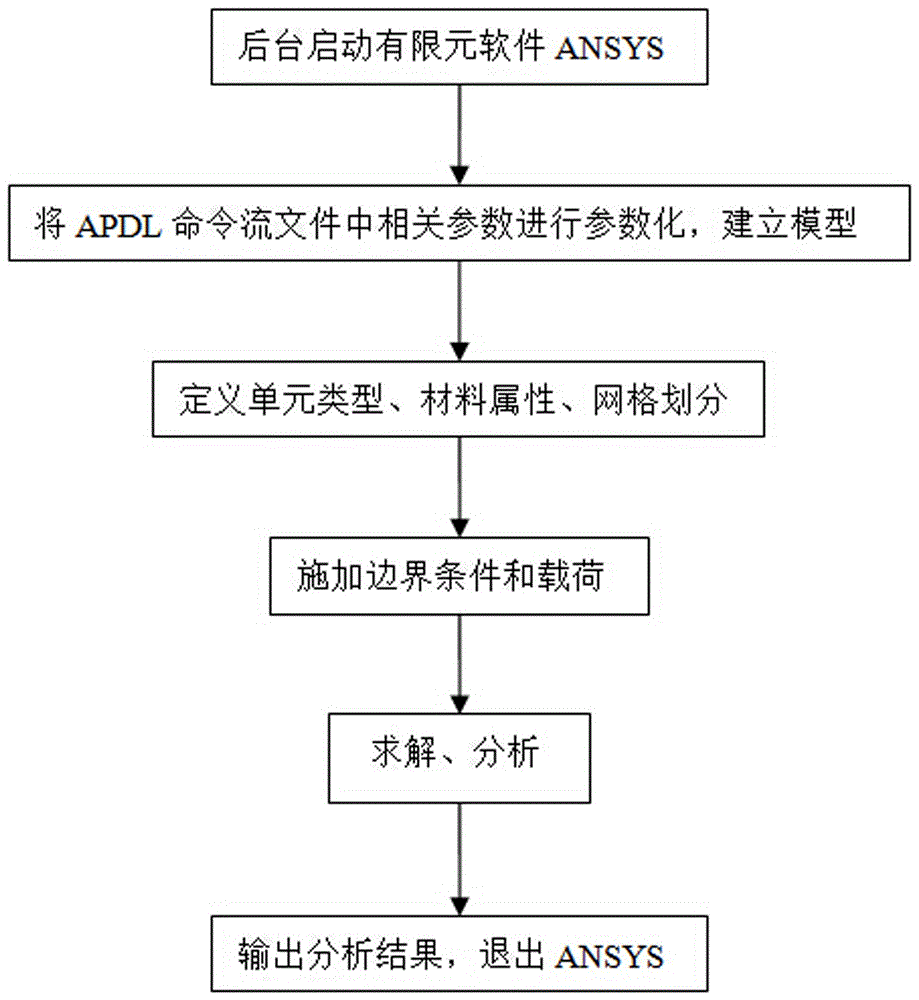

[0041] A variant design method that satisfies engineering constraints, including the steps of: Solidworks parametric 3D modeling, development of a parametric variant design user interface, writing model parameters and APDL command streams in Excel, and modifying and updating according to user interface parameter input , Start ANSYS in the background to automatically read the updated Excel modeling and analysis, automatically modify parameters and analysis until the output meets the engineering constraints, and the results are returned to the CAD remodeling model and Excel data update, figure 1 It is the main flow chart, and the specific steps are as follows:

[0042](1) An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com